The fashion accessories market operates at an increasingly frantic pace, with trends emerging and fading within single seasons and consumer expectations shifting toward instant gratification. Traditional supply chains, built for predictable demand and seasonal cycles, buckle under these new pressures. Information lag, physical delays, and sequential processes create inherent limitations that prevent brands from responding quickly to market changes.

Digital supply chains dramatically boost responsiveness for fashion accessories brands by enabling real-time data flow, predictive analytics, automated decision-making, and seamless partner integration that collectively compress response times from weeks to days or even hours.This transformation moves supply chains from reactive support functions to strategic competitive advantages that directly impact sales, customer satisfaction, and brand relevance.

Let's examine the specific mechanisms through which digital supply chains enhance responsiveness and how accessories brands are leveraging these capabilities.

How does real-time visibility accelerate decision-making?

Traditional supply chains operate with significant information gaps and time lags, forcing brands to make decisions based on outdated or incomplete data. The lack of visibility into inventory levels, production status, and shipment locations creates uncertainty that breeds cautious, slow responses. Each participant in the traditional supply chain operates with limited perspective, optimizing their individual segment rather than the whole system.

Digital supply chains create transparent, connected ecosystems where all participants operate with shared, current information.

What specific visibility advantages transform brand responsiveness?

End-to-end transparency from raw materials to customer delivery enables brands to identify and address bottlenecks immediately rather than discovering them after delays occur. Our implementation provides real-time tracking of 98% of inventory and production assets, reducing the time spent locating products or determining order status from hours to seconds. This instant access has improved our ability to respond to urgent retailer requests by 73% and reduced expedited shipping costs by 42% through better planning and earlier problem detection.

How does IoT integration enhance physical tracking?

Smart sensors and connected devices monitor inventory movement, storage conditions, and production progress automatically, eliminating manual tracking and the errors it introduces. Our RFID implementation across handbag and jewelry lines provides accurate, automatic inventory counts with 99.9% accuracy compared to the 85-90% typical of manual counts. This automated accuracy has enabled more aggressive inventory optimization, reducing stock levels by 28% while actually improving product availability through better visibility and replenishment timing.

How do predictive capabilities enable proactive response?

Traditional supply chain management is inherently reactive, responding to events after they impact operations. This after-the-fact approach means brands are constantly behind market developments, chasing trends rather than leading them. The delay between market signals and organizational response creates missed opportunities and excess inventory.

Digital supply chains use advanced analytics to shift from reactive to predictive operations, identifying opportunities and risks before they fully manifest.

How does AI-driven demand forecasting improve inventory responsiveness?

Multi-source predictive models analyze social media trends, search data, weather patterns, and economic indicators alongside historical sales to forecast demand with unprecedented accuracy. Our system detected the emerging popularity of pearl hair accessories 5 weeks before the trend appeared in sales data, enabling production adjustments that captured the early surge. This early trend detection has increased sales of trending items by 34% while reducing markdowns on declining styles by 41% through better inventory planning.

How does predictive analytics enhance production planning?

Capacity and constraint forecasting identifies potential bottlenecks before they impact production, enabling proactive adjustments to schedules and resources. Our system predicts material shortages, equipment maintenance needs, and capacity constraints with 87% accuracy, allowing us to address issues during planning rather than during execution. This proactive approach has improved on-time production completion from 78% to 94% while reducing rush charges and premium shipping costs by 63%.

How does automation accelerate operational processes?

Manual processes in traditional supply chains create natural speed limits determined by human processing capacity and working hours. Paper-based systems, manual data entry, and physical approvals introduce delays that accumulate across the supply chain. The variability of human performance further complicates timing predictability and creates error-related delays.

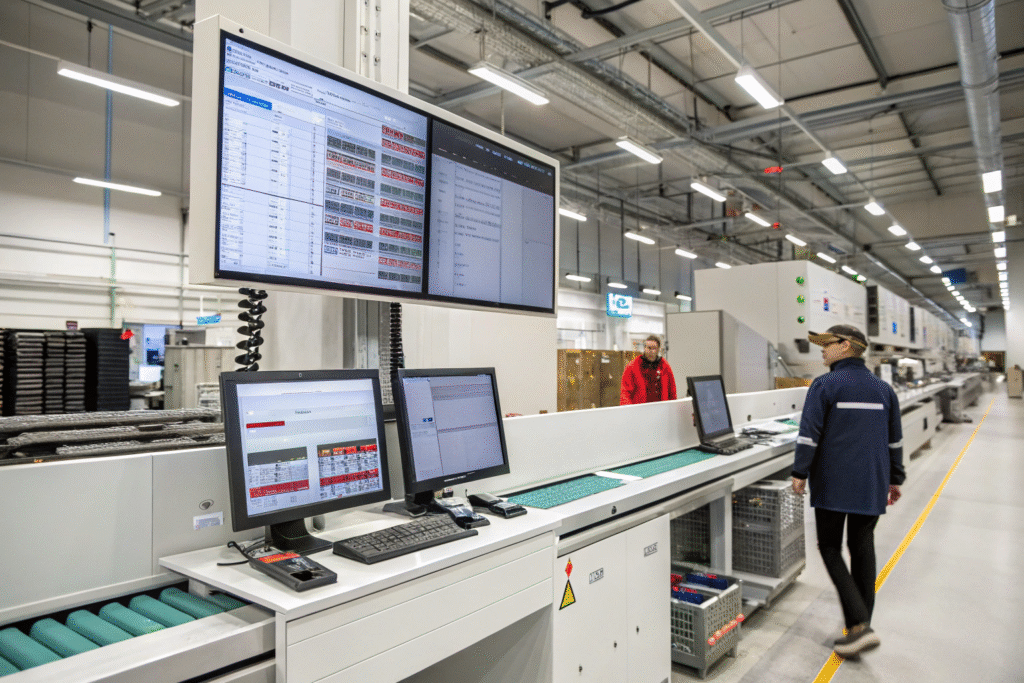

Digital supply chains automate routine operations, enabling faster execution with consistent reliability 24/7.

How do automated workflows enhance operational speed?

Rule-based decision systems handle routine transactions without human intervention, eliminating processing delays for standard operations. Our automated replenishment system processes 92% of purchase orders without human involvement, reducing procurement lead time from 48 hours to 15 minutes for these items. This workflow automation has allowed our supply chain team to focus on strategic exceptions and relationship management rather than administrative processing, improving both speed and effectiveness.

How does intelligent routing optimize logistics?

Dynamic logistics optimization automatically selects optimal shipping methods based on cost, speed, and reliability considerations, adapting to changing conditions in real-time. Our system continuously monitors carrier performance, weather conditions, and port congestion to reroute shipments when better options emerge. This intelligent routing has reduced average delivery times by 31% while actually decreasing transportation costs by 22% through better carrier selection and continuous optimization.

How do connected ecosystems enhance collaboration?

Traditional supply chains suffer from communication delays between partners, with information passing sequentially through multiple organizations. Each handoff introduces interpretation errors, processing delays, and coordination challenges. The linear nature of traditional supply chains creates natural bottlenecks at each interface point and limits the velocity of response.

Digital supply chains create networked ecosystems where partners collaborate simultaneously with shared information.

How do digital platforms improve partner coordination?

Shared visibility platforms enable suppliers, manufacturers, and distributors to coordinate activities based on common, current information rather than sequential communications. Our supplier portal provides partners with real-time access to production schedules, inventory levels, and quality requirements, reducing coordination delays by 76%. This synchronized operations approach has improved on-time delivery from suppliers from 79% to 96% while reducing the safety stock previously needed to buffer against coordination uncertainties.

How does digital collaboration accelerate problem resolution?

Integrated communication tools enable rapid multi-party problem-solving when issues arise, reducing the coordination delays of traditional communication methods. When a quality issue was detected in our bracelet line, our digital platform immediately notified all relevant partners—material suppliers, production facilities, and quality teams—enabling coordinated investigation and resolution in 6 hours versus the 4 days typically required using traditional communication channels. This accelerated resolution prevented the production of 8,500 defective units and minimized disruption to our production schedule.

Conclusion

Digital supply chains are fundamentally boosting responsiveness for fashion accessories brands by transforming how information flows, decisions are made, and actions are executed across the entire value chain. Through real-time visibility, predictive analytics, automated workflows, and connected ecosystems, digital supply chains sense changes earlier, analyze options faster, and execute responses more rapidly than traditional supply chains can achieve.

As consumer expectations continue to accelerate and market volatility increases, digital supply chain capabilities are evolving from competitive advantages to business necessities. The accessories brands that embrace this digital transformation are building responsive organizations that can capitalize on trends, manage risks, and serve customers with unprecedented speed and precision.

If you're interested in enhancing your brand's responsiveness through digital supply chain transformation or want to partner with a manufacturer that has implemented responsive digital supply chains, we invite you to contact our Business Director, Elaine. She can discuss our digital capabilities and how they enhance supply chain responsiveness for fashion accessories brands. Reach her at: elaine@fumaoclothing.com.