Traditional knitted beanie manufacturing often operates with disconnected processes, creating inefficiencies, quality inconsistencies, and communication gaps between departments. The implementation of connected production systems represents a transformative approach that integrates every aspect of manufacturing into a cohesive, data-driven ecosystem. Through our successful implementation across our knitting facilities, we've documented clear pathways to connectivity that deliver remarkable improvements in efficiency, quality, and responsiveness.

Implementing connected production systems for knitted beanie manufacturing requires integrating IoT sensors on knitting machines, establishing centralized data platforms, automating workflow coordination, and creating real-time visibility systems that connect design, production, quality control, and logistics.This digital transformation turns isolated manufacturing steps into a unified, intelligent production organism.

Connected manufacturing represents a fundamental shift from sequential to simultaneous processes. Let's explore the practical implementation strategies that can transform your knitted beanie production into a seamlessly connected system.

What infrastructure foundations support production connectivity?

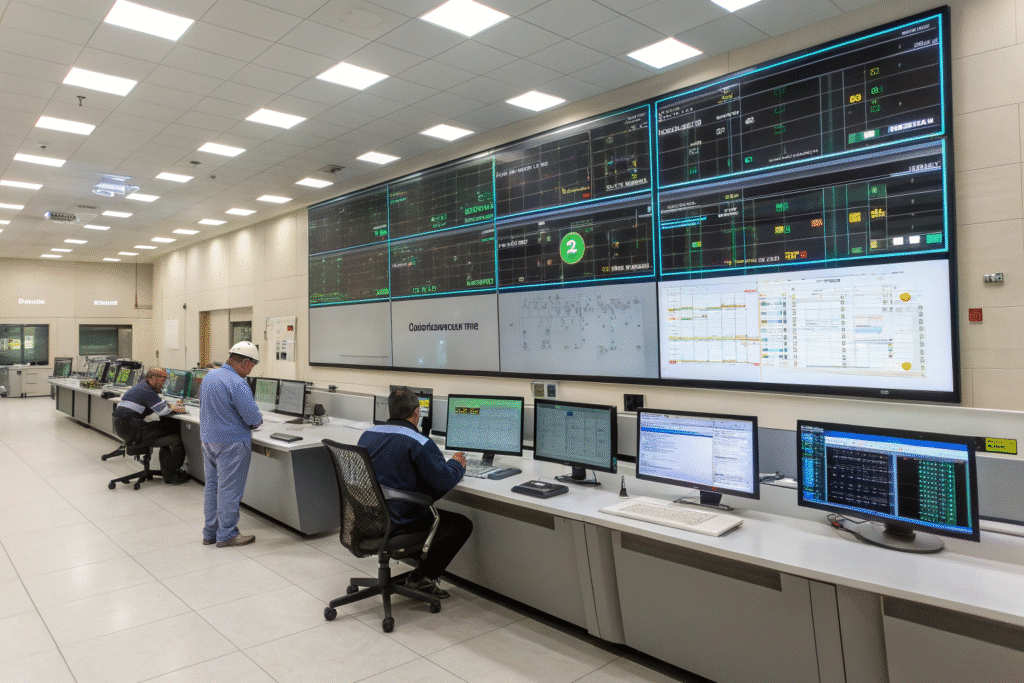

Before implementing connected systems, manufacturers must establish the technological infrastructure that enables seamless communication between equipment, software, and personnel. This foundation transforms traditional knitting facilities into smart factories capable of real-time data exchange and coordinated action.

The infrastructure layer consists of both hardware and software components that collectively create the nervous system of connected beanie manufacturing.

How do IoT sensors enable machine connectivity?

Traditional knitting machines operate as isolated islands of production. We retrofit our knitting machines with industrial IoT sensors that monitor critical parameters including production speed, yarn tension, needle status, and energy consumption. These sensors connect via wireless mesh networks that ensure reliable data transmission even in electromagnetically noisy industrial environments. The data collected provides real-time visibility into machine status, enabling predictive maintenance that reduces downtime by up to 45%. For beanie manufacturing specifically, we install specialized tension sensors that detect yarn variations that might affect fabric quality, allowing immediate adjustments before defective products are produced. This sensor network forms the sensory foundation of our connected production system.

What data architecture supports manufacturing integration?

Collecting data is meaningless without structures to organize and contextualize it. We've implemented a unified data platform that ingests information from all production sources—knitting machines, quality cameras, inventory systems, and order management. This platform uses standardized data models that ensure information from different systems can be correlated and analyzed together. For beanie production, we've developed specialized data schemas that capture knit-specific parameters like stitch density, pattern complexity, and elastane content. The platform includes data lakes for raw information and data warehouses for structured analysis, enabling both real-time monitoring and historical trend analysis. This architectural foundation makes connected intelligence possible rather than just connected equipment.

How can production processes be digitally connected?

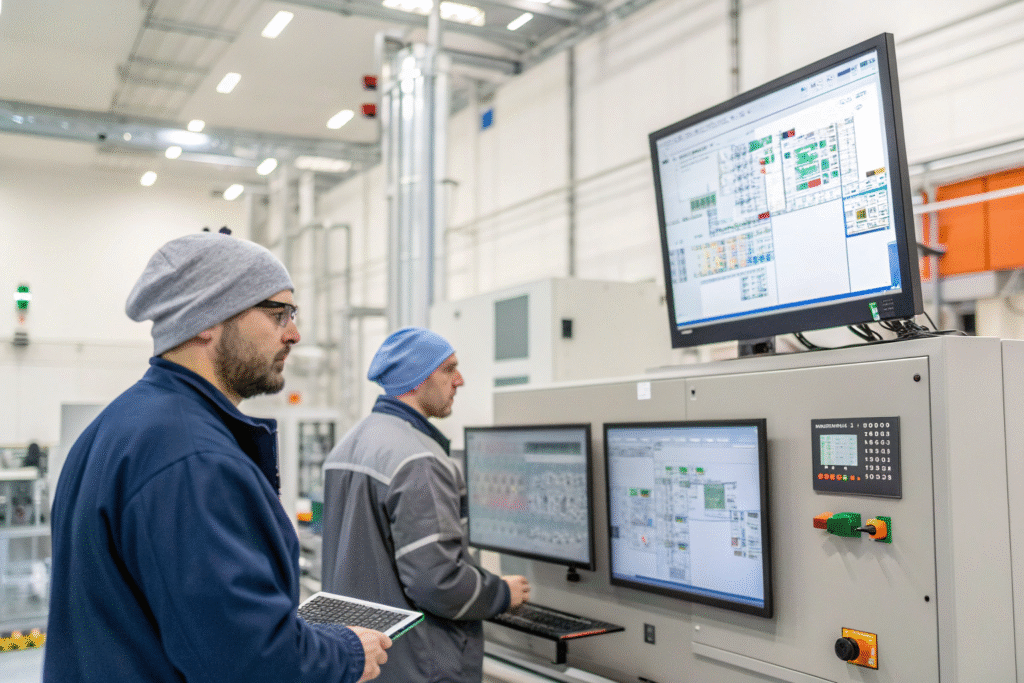

With infrastructure established, the next implementation phase focuses on connecting manufacturing processes into coordinated workflows. This digital thread links design, planning, production, and quality assurance into a seamless sequence that eliminates traditional handoff delays and information gaps.

Process connectivity transforms sequential operations into synchronized activities that respond dynamically to changing conditions and priorities.

What digital workflow systems coordinate production?

Traditional beanie manufacturing suffers from departmental silos where information moves slowly between teams. We've implemented digital workflow platforms that automatically route information and tasks between design, production planning, knitting operations, and finishing departments. When a new beanie design is approved, the system automatically generates manufacturing instructions, reserves materials, schedules machine time, and alerts quality teams about inspection requirements—all without manual intervention. The platform includes escalation protocols that automatically alert supervisors if processes deviate from planned timelines. This connectivity has reduced our order-to-production time by 60% while eliminating the communication errors that traditionally caused rework and delays.

How does machine-to-machine communication enhance efficiency?

Knitting machines operating in isolation cannot optimize overall production flow. Our connected system enables direct machine-to-machine communication where equipment shares status information and coordinates activities. When one machine completes a beanie batch, it automatically notifies downstream equipment and material handling systems to prepare for the next operation. The machines collectively optimize production sequences based on real-time conditions—perhaps prioritizing urgent orders when materials arrive early or adjusting speeds to balance workload across the facility. This machine coordination has increased our overall equipment effectiveness by 28% while reducing the manual supervision previously required to coordinate production steps.

How can quality management integrate into connected systems?

Quality assurance traditionally occurs at the end of production, creating costly delays when issues are detected. Connected systems integrate quality monitoring throughout manufacturing, enabling immediate correction and preventing the amplification of defects.

Integrated quality transformation moves inspection from a separate function to an embedded characteristic of the connected production ecosystem.

How do computer vision systems provide real-time quality data?

Traditional quality inspection happens after knitting completion, allowing defects to propagate through multiple production stages. We've installed computer vision systems at each knitting station that continuously monitor fabric quality as beanies are produced. These systems detect defects like dropped stitches, tension variations, pattern errors, and color inconsistencies in real-time. When issues are detected, the system automatically alerts operators and can, in some cases, initiate self-correction procedures on the knitting machines. The quality data is integrated with production records, creating complete quality histories for each beanie batch. This approach has reduced our defect rate by 75% while virtually eliminating the material waste previously generated by undetected knitting errors.

How does predictive quality analysis prevent defects?

Connected systems don't just detect defects—they predict and prevent them. Our predictive quality algorithms analyze production data to identify conditions that typically lead to quality issues. The system might detect that certain yarn lots produce more tension variations or that specific pattern combinations increase stitch error probability. Using these insights, the system automatically adjusts machine parameters or flags items for enhanced inspection before defects occur. For beanie production, we've trained these systems on thousands of historical quality incidents, enabling remarkably accurate prediction of issues based on subtle production signatures. This proactive quality approach has transformed our quality management from reactive detection to preventive assurance.

How can supply chain elements connect to production?

True production connectivity extends beyond factory walls to incorporate suppliers, logistics partners, and customers. This extended connectivity optimizes material flow, inventory levels, and delivery performance while enhancing responsiveness to market changes.

Supply chain integration creates a truly connected ecosystem where production responds dynamically to real-world conditions rather than operating on fixed schedules and forecasts.

How does supplier integration optimize material flow?

Yarn and material availability directly impacts beanie production efficiency. Our connected systems include supplier integration portals that share production schedules with material suppliers, enabling them to align their operations with our needs. The system automatically generates replenishment orders based on real-time consumption data, maintaining optimal inventory levels without manual intervention. For critical materials, we've established vendor-managed inventory arrangements where suppliers monitor our stock levels and initiate shipments automatically. This connectivity has reduced our raw material inventory by 30% while completely eliminating production stoppages due to material shortages—a common problem in traditional knitting operations.

How does customer connectivity enhance responsiveness?

Traditional manufacturing operates on forecasts that often misalign with actual market demand. Our connected systems include customer integration channels that receive real-time sales data from retail partners, enabling production to respond immediately to selling patterns. If a particular beanie style sells faster than anticipated, the system automatically adjusts production priorities and material allocations to increase output. For custom beanie programs, customers can directly input specifications through web interfaces that automatically generate manufacturing instructions. This demand-driven approach has reduced our finished goods inventory by 40% while improving our order fulfillment rate to 98.7%—transforming our business from push-based to pull-based manufacturing.

Conclusion

Implementing connected production systems for knitted beanie manufacturing requires a systematic approach that builds from technological infrastructure through process integration, quality embedding, and supply chain connectivity. This transformation delivers remarkable improvements in efficiency, quality, and responsiveness that provide significant competitive advantages in fast-fashion accessory markets. Companies that successfully implement these connected systems position themselves as industry leaders capable of delivering superior products with shorter lead times and greater customization capabilities.

If you're ready to transform your knitted beanie manufacturing through connected production systems, we invite you to contact our Business Director, Elaine. Our implementation experience and technical expertise can guide your connectivity journey to achieve similar efficiency and quality breakthroughs. Reach her at: elaine@fumaoclothing.com.