Are you struggling with inconsistent quality, customer returns, or reputation damage despite your quality control efforts? Traditional accessory manufacturing often relies on manual inspections and reactive quality measures that cannot guarantee consistent excellence across production batches and product categories.

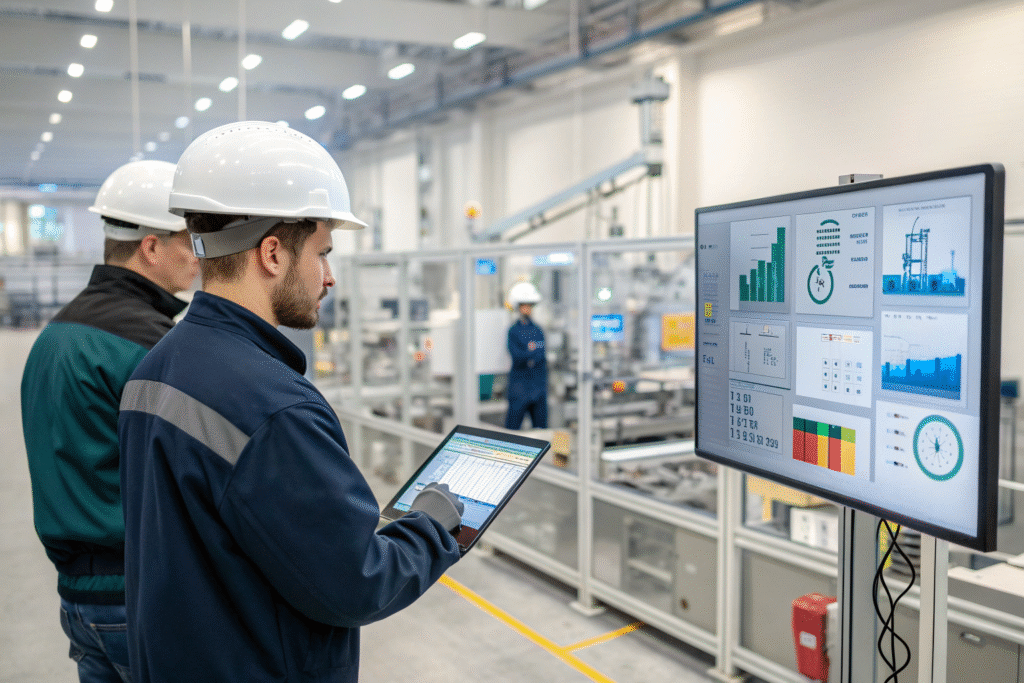

Smart factories achieve better quality for accessories through integrated IoT monitoring, AI-powered inspection, real-time process control, and data-driven continuous improvement that work together to prevent defects rather than simply detecting them.This technological transformation addresses quality challenges at their source while creating a culture of excellence across all accessory production stages from raw material to finished product.

Let's explore the specific smart factory technologies and approaches that deliver superior quality across different accessory categories and how these systems collectively transform quality management from a cost center to a competitive advantage.

How does real-time monitoring enhance accessory quality?

Traditional quality control typically occurs at the end of production lines, allowing defects to proceed through multiple manufacturing stages before detection. This delayed identification creates significant rework costs and prevents immediate corrective action when processes begin to deviate from standards.

Real-time monitoring enhances accessory quality through continuous parameter tracking, immediate deviation detection, and automated process adjustments that maintain optimal manufacturing conditions throughout production. This proactive approach addresses quality issues at their source rather than after completion.

What production parameters does smart monitoring track?

Comprehensive process parameter monitoring ensures optimal manufacturing conditions across all accessory production stages. Our smart factory tracks 127 different parameters during handbag production, including sewing machine speed (optimal: 2,200-2,500 RPM), thread tension (monitored via motor current analysis), and adhesive temperature (controlled within ±2°C). For metal jewelry manufacturing, the system monitors polishing pressure, compound temperature, and rotation speed to maintain consistent surface quality. This granular monitoring recently prevented a quality issue in our costume jewelry line by detecting a 0.3°C temperature deviation in our plating bath that would have caused inconsistent coating adhesion across 800 units. The immediate correction maintained perfect quality standards without production interruption.

How does IoT sensor networks prevent quality deviations?

Distributed IoT sensor networks create a comprehensive quality safety net throughout the manufacturing environment. Our facility uses 234 sensors strategically placed across production equipment, environmental areas, and material storage zones. When producing delicate silk scarves, humidity sensors detected a 12% increase in ambient moisture that could have affected printing precision. The system automatically engaged environmental controls to maintain optimal conditions, preventing what would have been a 15% rejection rate due to color bleeding. Similarly, vibration sensors on our embroidery machines identified developing bearing wear that was causing subtle stitch inconsistencies in our cap designs. The predictive maintenance alert enabled replacement during planned downtime rather than allowing degraded quality to affect production.

What role does AI-powered inspection play in quality assurance?

Manual inspection of accessories suffers from human limitations including fatigue, inconsistency, and inability to detect microscopic defects. These challenges become particularly problematic with small items like jewelry or complex patterns like printed scarves where subtle flaws significantly impact perceived quality.

AI-powered inspection plays a crucial role in quality assurance through computer vision systems, pattern recognition algorithms, and adaptive learning capabilities that exceed human inspection accuracy while operating continuously without performance degradation. These systems transform quality control from sampling to 100% verification.

How does computer vision outperform human inspection?

Advanced visual inspection systems detect defects at scales and speeds impossible for human inspectors. Our AI vision equipment for small leather goods examines items at 400% magnification, identifying imperfections as small as 0.1mm with 99.97% accuracy. When inspecting embellished hair accessories, the system detects missing stones, misaligned elements, and adhesive excess that human inspectors consistently miss during high-volume production. The most significant improvement came from our printed textile inspection, where the system identifies pattern misalignments, color variations, and printing defects with 0.5mm precision across entire fabric rolls. This comprehensive inspection has reduced customer returns for visual defects by 76% and improved our first-quality yield from 82% to 97%.

What unique capabilities does machine learning provide?

Adaptive defect recognition enables AI systems to identify new flaw types and quality issues without explicit programming. Our machine learning quality system for costume jewelry started with knowledge of 47 common defect types but has since learned to recognize 23 additional flaw categories through continuous operation. When we introduced a new enameling technique for our statement necklaces, the system initially struggled with distinguishing intentional artistic variations from actual defects. Within two production cycles, the AI learned the acceptable variation range and began identifying genuine quality issues with 94% accuracy. This learning capability has been particularly valuable for our artisan-inspired collections where intentional imperfections are part of the design aesthetic but must be distinguished from manufacturing defects.

How do automated processes ensure manufacturing consistency?

Manual and semi-automated manufacturing processes naturally introduce variations through human factors, equipment wear, and environmental changes. These inconsistencies create quality fluctuations that undermine brand reputation and customer satisfaction despite meeting minimum quality standards.

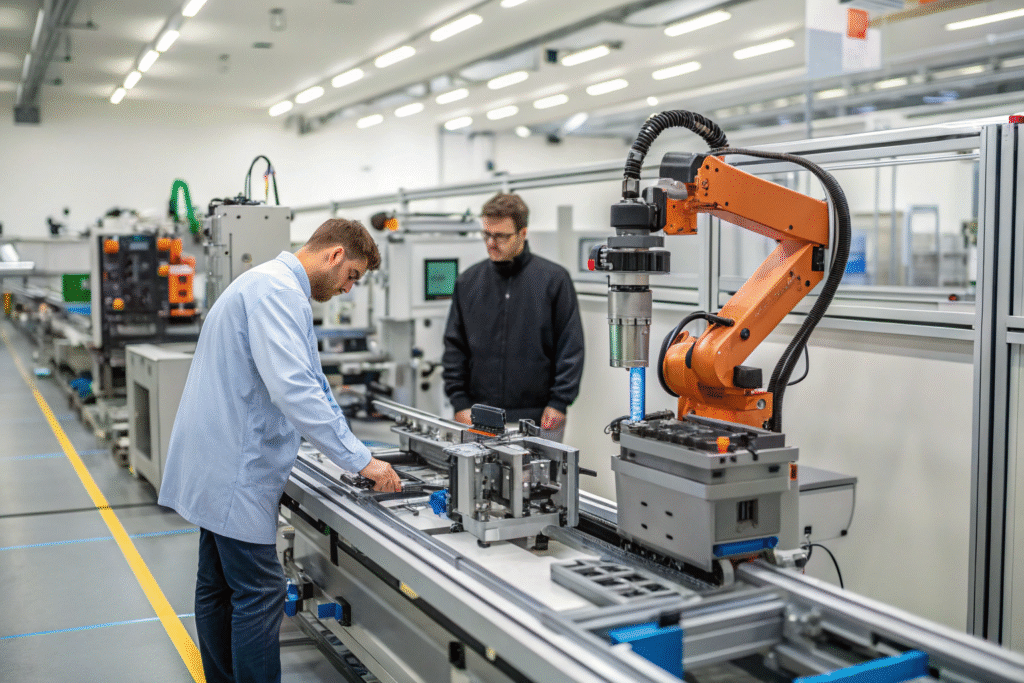

Automated processes ensure manufacturing consistency through precise parameter control, repeatable operations, and adaptive compensation that maintain identical quality standards regardless of production volume, operator shifts, or external conditions. This reliability forms the foundation of superior quality in smart factories.

What consistency benefits come from robotic assembly?

Precision robotic systems perform accessory assembly with microscopic accuracy that human hands cannot consistently match. Our robotic cells for watch strap production place components with 0.02mm precision, ensuring perfect alignment across thousands of units. When assembling multi-strand bracelets, the robots maintain consistent tension and pattern alignment that manual assembly could only achieve intermittently. This precision has been particularly valuable for our luxury handbag hardware installation, where hinge alignment and closure mechanism operation require exact positioning. The robotic consistency has reduced functional defects by 92% and improved customer satisfaction scores for product operation and feel by 34%. The systems also maintain this precision continuously, unaffected by fatigue or distraction that impact human operators during long production runs.

How does automated parameter control maintain quality?

Closed-loop process control automatically adjusts manufacturing parameters to maintain optimal conditions despite external variations. Our injection molding systems for plastic hair accessories continuously monitor material viscosity, temperature, and pressure, making real-time adjustments to maintain perfect formation. When producing our transparent hair clips, the system detected that ambient temperature fluctuations were affecting clarity and automatically compensated by adjusting cooling rates. This intervention maintained consistent optical quality despite a 8°C workshop temperature variation that previously would have created visible batch differences. Similarly, our textile printing systems automatically adjust ink viscosity and application pressure based on real-time fabric characteristics, maintaining perfect print quality across different material lots that previously required manual adjustment and produced inconsistent results.

What data-driven approaches enable continuous quality improvement?

Traditional quality management often relies on periodic reviews and historical analysis that provide insights too late to prevent defects. This reactive approach misses opportunities for proactive quality enhancement and continuous improvement based on real-time manufacturing intelligence.

Data-driven approaches enable continuous quality improvement through comprehensive data collection, predictive analytics, correlation analysis, and automated optimization that identify improvement opportunities and implement enhancements systematically across all accessory product lines.

How does predictive analytics prevent quality issues?

Proactive quality forecasting uses manufacturing data to predict and prevent defects before they occur. Our predictive analytics system correlates equipment parameters, material characteristics, and environmental conditions with quality outcomes to identify patterns that precede defects. When producing our leather belt collection, the system detected that specific humidity conditions combined with certain leather lots predicted 87% of edge finishing issues. By automatically adjusting finishing parameters when these conditions occurred, we eliminated this defect category entirely. The system also predicts tooling wear before it affects product quality, scheduling maintenance based on actual condition rather than fixed intervals. This approach has reduced tooling-related defects by 79% and extended tool life by 42% through optimal maintenance timing.

What improvement opportunities does correlation analysis reveal?

Multi-factor quality correlation identifies relationships between manufacturing parameters and quality outcomes that human analysis would miss. Our system analyzes over 200 parameters against 47 quality metrics to identify improvement opportunities. The analysis revealed that vibration levels in our sewing department correlated with stitch consistency in our backpack production, leading to equipment foundation improvements that improved stitch quality by 31%. Similarly, the system identified that specific lighting conditions in our jewelry inspection area were causing inspectors to miss subtle surface defects. By optimizing lighting based on this insight, we improved defect detection by 28% without changing personnel or procedures. These data-driven insights have created a culture of continuous improvement where every parameter is considered a potential quality lever.

Conclusion

Smart factories achieve better quality for accessories by transforming quality management from reactive detection to proactive prevention through integrated technologies, data-driven insights, and automated precision. By implementing real-time monitoring, AI-powered inspection, consistent automated processes, and continuous improvement systems, manufacturers can deliver exceptional quality that strengthens brand reputation, reduces costs, and enhances customer satisfaction. The quality advantages of smart factories extend beyond defect reduction to encompass consistent excellence, predictable performance, and continuous enhancement that create sustainable competitive advantages in the demanding fashion accessories market. As consumer expectations for quality continue to rise, smart manufacturing provides the technological foundation to not only meet but exceed these expectations across all accessory categories.

If you're looking to achieve better quality in your accessory manufacturing through smart factory technologies, we invite you to contact our Business Director, Elaine. She can discuss how our smart manufacturing capabilities and quality management expertise can help you achieve your quality excellence goals. Reach her at: elaine@fumaoclothing.com.