Fashion accessories production planning has traditionally relied on historical data, manual forecasting, and experienced planners' intuition. This approach often leads to either overproduction that strains inventory budgets or underproduction that misses sales opportunities. The volatile nature of fashion trends, seasonal fluctuations, and unpredictable consumer behavior makes accurate planning particularly challenging for accessories with shorter lifecycles and diverse product variations.

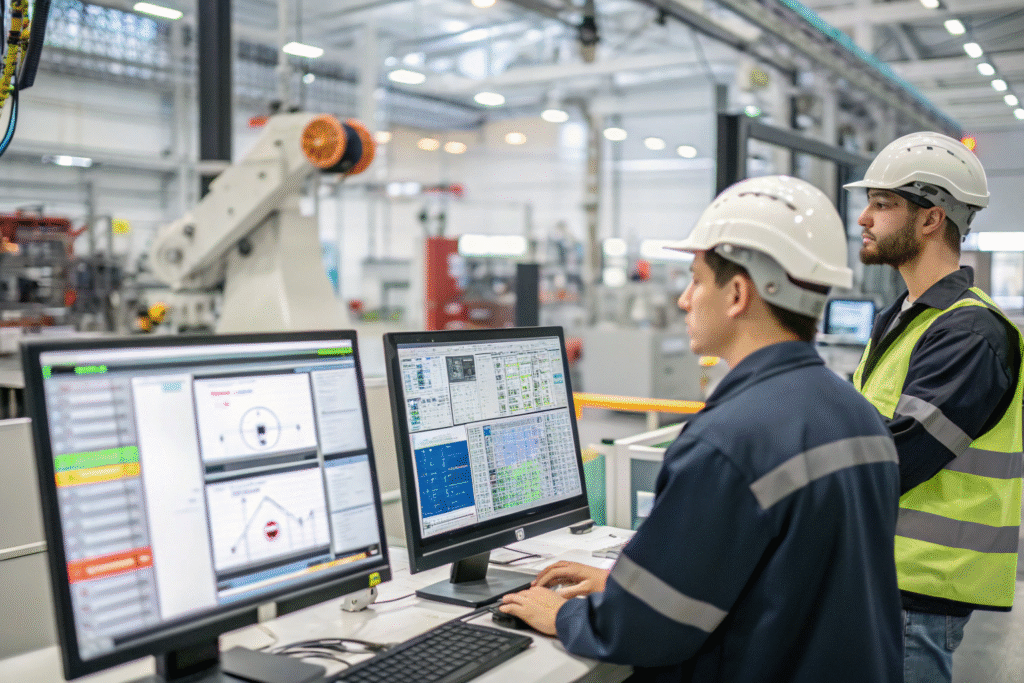

AI algorithms are revolutionizing fashion accessories production planning by processing complex datasets, identifying subtle patterns, predicting demand with unprecedented accuracy, and optimizing manufacturing schedules in real-time. These systems transform production planning from reactive guesswork to proactive, data-driven decision-making that balances efficiency with responsiveness in a rapidly changing market.

Let's examine the specific capabilities AI brings to production planning and how they're transforming accessory manufacturing operations.

How do AI demand forecasting models outperform traditional methods?

Traditional demand forecasting for fashion accessories typically relies on linear extrapolation of historical sales data, often missing subtle trend shifts, emerging patterns, and external influences. Human planners, no matter how experienced, cannot process the thousands of variables that simultaneously affect accessory demand across different markets, channels, and customer segments.

AI algorithms excel at detecting complex, non-linear relationships in data that escape traditional statistical methods and human analysis.

What data sources do AI algorithms analyze for accurate predictions?

Multi-dimensional data integration allows AI systems to process historical sales, social media trends, search query volumes, weather patterns, economic indicators, and even competitor activities simultaneously. Our AI implementation analyzes over 127 different data points for each accessory category, identifying that searches for "wide headbands" increase by 300% two weeks before unseasonably warm weather in specific regions. This comprehensive analysis has improved our forecast accuracy for seasonal accessories from 68% to 91%, dramatically reducing both stockouts and excess inventory.

How do machine learning models adapt to rapidly changing trends?

Continuous learning algorithms automatically update their predictions as new data becomes available, detecting trend shifts much earlier than human planners. Our system identified the emerging popularity of pearl-embellished hair accessories 6 weeks before the trend became apparent in sales data, allowing us to adjust production and capture the early market surge. This early trend detection has been particularly valuable for fast-fashion accessories where being first to market significantly impacts sales performance and margin preservation.

How does AI optimize production scheduling and resource allocation?

Traditional production scheduling often follows fixed cycles and capacity assumptions that cannot quickly adapt to changing priorities, material availability, or unexpected disruptions. This rigidity creates bottlenecks, underutilized resources, and missed deadlines when reality diverges from plans.

AI-driven scheduling introduces dynamic optimization that continuously rebalances resources and sequences to maximize efficiency while maintaining flexibility.

How do AI systems handle complex scheduling constraints?

Multi-objective optimization algorithms simultaneously consider due dates, changeover times, material availability, workforce skills, machine maintenance, and energy costs to create optimal production sequences. Our AI scheduling system reduced our average order completion time by 34% while actually decreasing overtime costs by 27% through better workload balancing and reduced machine changeovers. This efficiency improvement has been particularly valuable during peak seasons when multiple urgent orders traditionally created conflicts and delays.

What role does predictive maintenance play in production planning?

Equipment failure forecasting allows planners to schedule maintenance during natural production gaps rather than reacting to unexpected breakdowns. Our AI system analyzes equipment sensor data to predict maintenance needs with 94% accuracy, reducing unplanned downtime by 78% compared to our previous calendar-based maintenance approach. This proactive maintenance has significantly improved our on-time delivery rate and reduced the rush charges previously needed to recover from production interruptions.

How does AI enhance inventory management and material planning?

Fashion accessories manufacturing involves numerous raw materials, components, and finished goods with different lead times, minimum order quantities, and shelf-life considerations. Traditional inventory management often relies on safety stock formulas and reorder points that cannot adapt to changing consumption patterns or supply chain disruptions.

AI transforms inventory management from static rules to dynamic, predictive systems that optimize stock levels across the entire production ecosystem.

How does AI optimize raw material inventory?

Consumption pattern analysis combined with supplier lead time forecasting enables AI systems to maintain optimal material stocks while minimizing carrying costs. Our implementation reduced leather inventory by 32% while completely eliminating production stoppages due to material shortages through more accurate consumption forecasting and supplier performance analysis. This inventory optimization has freed significant working capital while actually improving production reliability.

How do AI systems handle component coordination for complex accessories?

Multi-level bill of materials optimization ensures that all components arrive synchronized for assembly, preventing the delays that occur when a single missing item holds up entire production runs. Our system for jewelry production coordinates the arrival of chains, clasps, stones, and packaging materials across 14 different suppliers, automatically adjusting orders when any component's availability changes. This supply synchronization has reduced our component-related production delays from occurring in 23% of orders to just 2% of orders.

How does AI improve responsiveness to supply chain disruptions?

The global nature of fashion accessories supply chains creates vulnerability to disruptions ranging from transportation delays and material shortages to geopolitical issues and natural disasters. Traditional planning systems struggle to rapidly reconfigure production and sourcing strategies when unexpected events occur.

AI systems excel at scenario analysis and dynamic reoptimization, enabling manufacturers to respond to disruptions with minimized impact.

How does AI enable rapid replanning during disruptions?

Real-time scenario simulation allows planners to evaluate multiple alternative approaches when disruptions occur, selecting the optimal response based on comprehensive impact analysis. When a key metal component supplier unexpectedly shut down, our AI system evaluated 47 alternative responses within minutes, recommending a combination of alternative sourcing, temporary design modifications, and production resequencing that limited the impact to just 8% of orders versus an estimated 35% impact using traditional methods. This resilience capability has become increasingly valuable as supply chain volatility has become the norm rather than the exception.

How does AI optimize transportation and logistics planning?

Multi-carrier optimization algorithms continuously evaluate shipping options based on cost, reliability, speed, and sustainability metrics. Our system automatically reroutes shipments when delays occur, selects optimal packaging configurations, and even consolidates orders to reduce transportation costs. This logistics intelligence has reduced our average shipping costs by 22% while improving on-time delivery performance from 84% to 96% despite increasing global supply chain challenges.

Conclusion

AI algorithms are transforming fashion accessories production planning from an art based on experience and intuition to a science driven by data and predictive analytics. By delivering more accurate demand forecasts, optimized production schedules, efficient inventory management, and resilient supply chain coordination, AI enables manufacturers to achieve previously impossible balances between efficiency and responsiveness.

As these technologies continue to evolve and become more accessible, AI-powered production planning will shift from competitive advantage to industry standard—enabling accessory manufacturers to thrive in an increasingly volatile, fast-paced, and demanding global marketplace.

If you're interested in implementing AI algorithms for your accessory production planning or want to partner with a manufacturer that leverages advanced planning technologies, we invite you to contact our Business Director, Elaine. She can discuss our AI capabilities and how they create more responsive and efficient production operations. Reach her at: elaine@fumaoclothing.com.