Are you concerned about over-automation in your accessory production or wondering where human craftsmanship still delivers irreplaceable value? While automation has transformed manufacturing, certain artistic and technical processes resist complete machine replacement due to their inherent need for human judgment, creativity, and adaptability.

Several accessory making processes cannot be fully replaced by machines, including creative design conception, artisan craftsmanship, complex material selection, quality judgment of natural materials, and adaptive problem-solving during production.These areas require human intuition, aesthetic judgment, and creative problem-solving that current technology cannot replicate, preserving essential roles for skilled artisans in an increasingly automated industry.

Let's explore the specific accessory manufacturing processes where human expertise remains irreplaceable and why these areas continue to depend on human skills despite technological advancements.

Why can't machines replicate creative design conception?

The initial creative process of accessory design involves inspiration, cultural understanding, and emotional intelligence that machines cannot genuinely replicate. While AI can generate patterns and variations, the fundamental creative spark and contextual understanding remain uniquely human capabilities.

Creative design conception cannot be replicated by machines because it requires emotional intelligence, cultural context understanding, and the ability to draw inspiration from abstract concepts and human experiences. These deeply human capabilities form the foundation of truly innovative accessory design that resonates emotionally with consumers.

What aspects of initial design inspiration remain human-dependent?

Conceptual creativity and emotional intelligence form the foundation of design that machines cannot authentically replicate. Our lead designers draw inspiration from cultural movements, personal experiences, and emotional responses that AI systems cannot genuinely feel or understand. When creating our artisan jewelry collections, designers incorporate storytelling elements and emotional narratives that connect with customers on a personal level. While machines can analyze trend data and generate variations, the original creative vision—the "spark" that makes a design compelling and emotionally resonant—comes from human experience and intuition. This human touch is particularly valued in our limited edition collections where each piece carries a story that transcends its physical attributes.

How does cultural context understanding require human designers?

Cultural intelligence and contextual understanding enable designers to create accessories that respectfully incorporate traditional elements while remaining commercially viable. Our design team includes members from diverse cultural backgrounds who understand the subtle nuances of incorporating traditional patterns, symbols, and techniques into contemporary accessories. When developing our ethnic-inspired scarf collection, human designers ensured cultural elements were used respectfully and appropriately, considering historical significance and contemporary sensitivity. Machines might replicate patterns mathematically but cannot understand the cultural meaning, historical context, or potential appropriation concerns that require human judgment and empathy.

Which artisan techniques resist full automation?

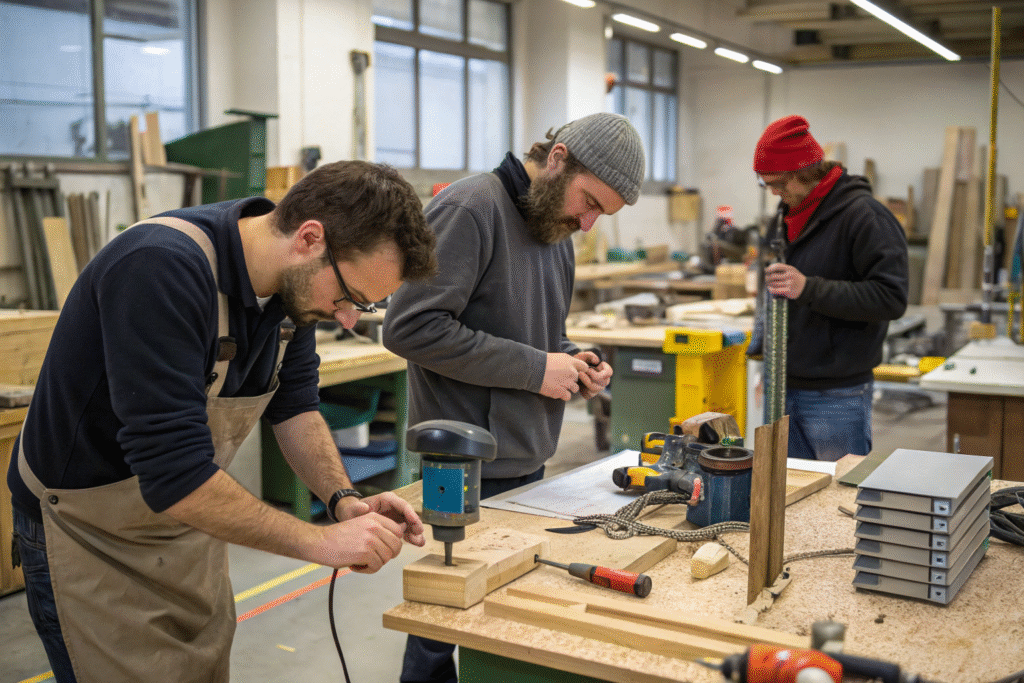

Many traditional artisan techniques have evolved over centuries and involve subtle hand movements, material feel, and adaptive responses that automated systems cannot duplicate. These techniques often produce the unique characteristics that define luxury and artisanal accessories.

Artisan techniques that resist full automation include hand-embroidery, leather tooling, certain metal-smithing operations, and free-form sculpting that require the adaptive pressure, rhythmic variation, and intuitive material response that only human artisans can provide. These techniques create the imperfections and unique qualities that define handmade luxury.

Why does hand-embroidery remain superior to machine alternatives?

Adaptive stitching and artistic interpretation make hand-embroidery irreplaceable for high-end accessories. Our artisans working on luxury handbags and decorative hair accessories adjust thread tension, stitch direction, and density in real-time based on material behavior and design requirements. While machines can replicate patterns with perfect consistency, they cannot adapt to material variations or incorporate the subtle artistic interpretations that make each hand-embroidered piece unique. The slight imperfections and human touch in our hand-beaded evening bags are actually valued characteristics that justify premium pricing and distinguish them from mass-produced alternatives. Customers specifically seek out these human-made nuances that signal quality and artistry.

What makes traditional leather tooling impossible to automate fully?

Intuitive material response and artistic pressure variation prevent complete automation of quality leather work. Our master leather craftsmen working on artisan belts and handbags develop a "feel" for the material that guides their tooling pressure, moisture application, and working speed. This tactile feedback loop allows them to adapt to natural variations in hide thickness, texture, and responsiveness—something machines programmed for consistency cannot accommodate. The hand-tooled patterns on our signature leather goods display depth variations and subtle asymmetries that customers recognize as marks of authentic craftsmanship rather than manufacturing defects. These characteristics actually increase the perceived value and individuality of each piece.

How does natural material selection require human judgment?

The selection and matching of natural materials like leather, wood, stones, and organic fibers involve aesthetic judgment, pattern recognition, and quality assessment that exceed current machine capabilities. These decisions often determine the final appearance and quality of the finished accessory.

Natural material selection requires human judgment because it involves assessing aesthetic qualities, predicting material behavior, matching patterns and grains, and making value decisions based on visual appeal and character rather than just measurable specifications. This subjective evaluation creates the unique character of artisanal accessories.

Why can't machines effectively match leather grains and characteristics?

Aesthetic pattern recognition and character assessment in natural materials requires human visual perception and experience. Our leather experts selecting materials for matched accessory sets can identify subtle grain patterns, color variations, and surface characteristics that machines might classify as defects but actually contribute to the material's character. When creating our high-end leather portfolios, craftsmen spend hours matching panels so grain patterns flow harmoniously across the piece—a subjective aesthetic decision that requires an eye for beauty and proportion that algorithms cannot replicate. This human curation ensures that natural materials are used to their best advantage, highlighting their unique beauty rather than treating variations as imperfections to be eliminated.

What makes gemstone and natural stone selection human-dependent?

Value judgment based on unique characteristics rather than standardized measurements makes gemstone selection particularly human-dependent. Our jewelry specialists evaluating stones for statement pendants and ring designs consider not just carat, clarity, and color, but how these elements interact to create stones with character and presence. Two stones with identical technical specifications can have completely different visual impacts based on cut, light performance, and unique inclusions. This nuanced evaluation requires human perception and experience, particularly for our artisan jewelry line where we specifically select stones with unique characteristics rather than seeking flawless uniformity. Customers appreciate that each piece features a stone with its own personality, selected by human experts for its unique beauty.

Where does adaptive problem-solving defeat automation?

Manufacturing complex accessories often presents unexpected challenges that require creative solutions, improvisation, and judgment calls that cannot be pre-programmed into automated systems. These situations test the limits of artificial intelligence and robotics.

Adaptive problem-solving defeats automation in situations requiring improvisation with material limitations, creative solutions to unexpected production issues, and judgment calls balancing quality with practicality. These scenarios demand the flexibility and creative thinking that remain uniquely human strengths in manufacturing.

How do human artisans solve unexpected material challenges?

Improvisational material management allows experienced craftspeople to adapt when materials behave unexpectedly. When a batch of vegetable-tanned leather for our belt collection arrived with unusual moisture content that affected tooling precision, our master leatherworker adjusted his technique, tool temperature, and finishing approach to accommodate the material's behavior. An automated system would have either rejected the material or produced inferior results following its programmed parameters. Similarly, when working with natural fiber materials for our summer hat collection, artisans adapt weaving tension and technique based on the specific characteristics of each fiber batch, ensuring quality results despite natural variations that would confuse automated equipment.

Why does prototype development require human intervention?

Creative iteration and intuitive adjustment during prototype development involves constant evaluation and modification that automated systems cannot replicate. Our design team creating prototypes for architectural jewelry pieces makes countless subtle adjustments based on how materials interact, how pieces feel when worn, and how designs translate from concept to physical form. This iterative process involves tactile evaluation, wear-testing, and aesthetic judgments that require human sensory perception and creative problem-solving. While 3D modeling and printing accelerate certain aspects, the final refinement of our signature cuff bracelets and statement necklaces requires human hands to adjust balance, comfort, and visual impact in ways that machines cannot comprehend or execute.

Conclusion

While automation has transformed many aspects of accessory manufacturing, numerous processes remain firmly in the domain of human expertise due to their requirement for creativity, judgment, adaptation, and emotional intelligence. The most successful accessory manufacturers recognize that the future lies not in choosing between automation and craftsmanship, but in strategically integrating both—using machines for consistency and efficiency where appropriate, while preserving and valuing human skills where they deliver irreplaceable quality and character. This balanced approach creates products that combine manufacturing precision with artistic soul.

If you're looking to preserve artisanal quality while implementing appropriate automation in your accessory production, we invite you to contact our Business Director, Elaine. She can discuss how our hybrid approach maintains craftsmanship while leveraging technology efficiently. Reach her at: elaine@fumaoclothing.com.