You're designing a new scarf or beanie line and need a unique pattern. You see amazing designs online, but you're stuck: should you choose jacquard or print? Making the wrong choice can lead to a product that looks cheap, feels uncomfortable, or blows your budget. For fashion buyers, this technical mistake can turn a promising collection into a warehouse of unsold goods.

The core difference between jacquard and print lies in how the pattern is created. Jacquard is a weaving technique where the pattern is structurally integrated into the fabric by controlling individual warp threads. Printing is a surface application where color and design are applied onto an already-woven fabric. At Shanghai Fumao Clothing, we produce both types daily for our accessory lines. The right choice depends on your desired look, texture, budget, and production volume. Understanding this is key to developing a successful product.

Let’s unravel the details so you can confidently specify the perfect technique for your next accessory collection.

What is Jacquard Weaving and How is it Made?

Imagine a pattern that isn't just on the fabric but is the fabric itself. That's jacquard. It's not a separate layer; the colored threads are woven to form the design during the loom process. This technique creates a rich, often textured, and reversible pattern that is durable and has a premium feel. For buyers looking for classic, high-end scarves, shawls, or even intricate hat bands, jacquard is often the gold standard.

Jacquard weaving uses a special loom—historically using punch cards, now computer-controlled—that can individually lift thousands of warp threads. This allows for complex, detailed patterns like florals, damasks, or geometrics to be woven directly. The resulting fabric is characterized by its structural integrity, potential for texture (the pattern can be raised), and color complexity from the interplay of dyed threads.

Mastering this technique is a hallmark of a manufacturer with deep design and development capability, as it involves significant technical planning and expertise.

What Are the Key Characteristics of Jacquard Fabric?

Jacquard fabrics have distinct traits that set them apart. First, they are reversible; the pattern is visible on both sides, though often in inverted colors (a positive/negative effect). This makes it ideal for accessories like scarves and shawls that are seen from multiple angles. Second, they have a tactile texture. You can often feel the raised pattern with your fingers. Third, they are extremely durable; since the design is woven in, it won't peel or wash out. Common fibers used include cotton, polyester, silk, and wool blends. The feel can range from light and crisp to heavy and drapey, depending on the yarn.

Is Jacquard Weaving Expensive and Slow?

Generally, yes, jacquard is more costly and time-consuming than printing, especially for smaller orders. The cost comes from the complex loom setup. Creating the digital weave file and setting up the loom is a fixed cost. This makes minimum order quantities (MOQs) higher to amortize that setup cost. The weaving process itself is also slower than fabric printing. However, for larger runs, the per-unit cost becomes more competitive. The premium price is justified by the luxury feel, durability, and unique structural quality it offers—a value that brands like Shanghai Fumao Clothing help clients communicate to their end customers.

What is Fabric Printing and How is it Applied?

Now, think of printing like a high-quality tattoo on fabric. The base cloth (which can be any weave—plain, satin, etc.) is first produced, and then the design is applied to its surface. This method unlocks unlimited color possibilities, photorealistic images, and is fantastic for bold, graphic designs or detailed artwork that would be impossible to weave.

Modern fabric printing, especially digital printing, has revolutionized the industry. It allows for rapid prototyping, extremely low MOQs, and design changes with minimal cost. For fashion accessories responding to fast trends, like seasonal bandanas, printed scarves, or novelty tote bags, printing is the go-to for its flexibility and speed to market.

The quality of print, however, hinges on a factory's stringent quality control and certifications to ensure colorfastness and print durability.

What are the Main Types of Fabric Printing?

Several printing methods are used for accessories, each with pros and cons:

- Digital Printing (Inkjet): The most versatile for fashion. It's like a giant desktop printer for fabric. It's ideal for complex designs with many colors, gradients, and photorealistic images. MOQs are very low, making it perfect for test runs and small collections. The feel is generally soft, as the ink saturates the fibers.

- Screen Printing: A traditional method where a separate screen is made for each color. It's cost-effective for simple designs with few colors and large production runs (e.g., logoed baseball caps or uniform scarves). The print can have a slightly thicker, more palpable hand-feel.

- Sublimation Printing: Used primarily on polyester fabrics. The dye turns into a gas and bonds with the synthetic fibers. The result is extremely vibrant, wash-resistant colors that won't crack or peel. It's ubiquitous in sporty accessories like performance headbands and activewear scarves.

Is Printed Fabric Less Durable Than Jacquard?

It depends on the print technique and fabric base. A poorly done print on cheap fabric can crack, fade, or wash out. However, a high-quality print with proper fixation and finishing on a suitable fabric can be very durable. Digital prints on treated natural fibers (like silk or cotton) or sublimation prints on polyester offer excellent colorfastness. The durability is in the surface layer, so it can eventually wear with extreme abrasion—unlike jacquard, where the pattern is integral. Reputable suppliers ensure durability through testing, as guided by standards from organizations like the American Association of Textile Chemists and Colorists (AATCC).

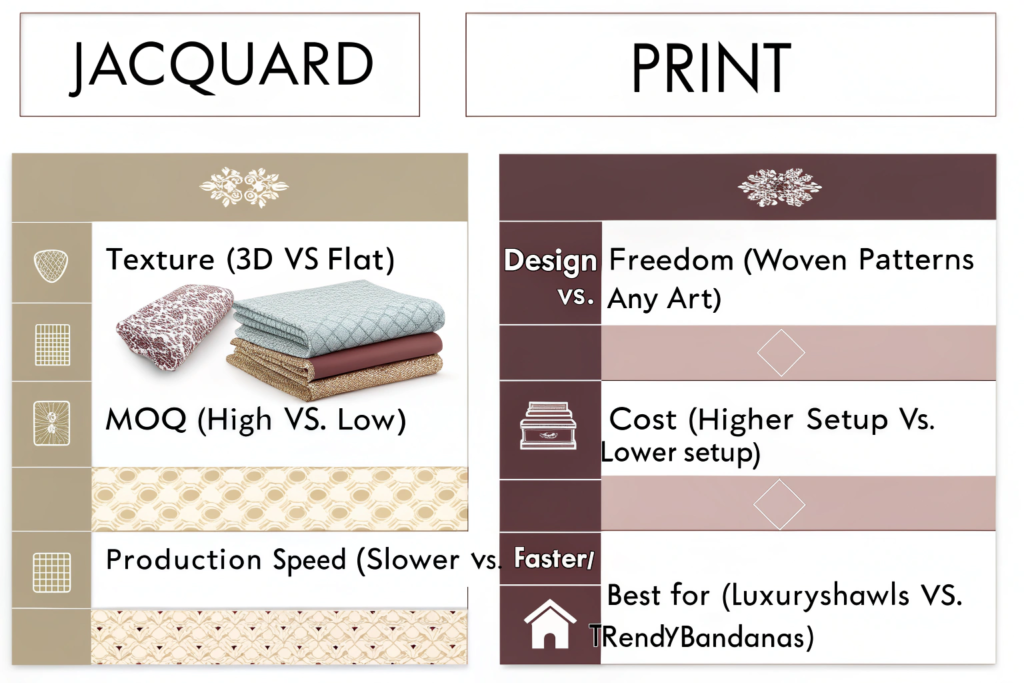

Side-by-Side Comparison: Jacquard vs. Print

To make the best sourcing decision, you need to see them side-by-side. Each method excels in different areas, and your product's purpose should guide your choice. Choosing print for a heritage-style wool scarf might make it feel insubstantial, while choosing jacquard for a trendy, photo-based design would be prohibitively expensive and technically limited.

Here’s a breakdown of how they compare across key decision-making factors for accessory production.

This comparison is crucial when planning your logistics and sourcing strategy, as lead times and costs differ significantly.

How Do They Compare on Design Freedom and Color?

This is the most significant trade-off.

- Jacquard: Design freedom is constrained by the weaving process. Very fine details, subtle gradients, and an unlimited number of colors are difficult or impossible. Designs work best with clear, defined shapes and a limited color palette (though the interweaving of threads can create the illusion of more colors). It excels in classic, repeating patterns.

- Print: Offers near-total design freedom. Photographs, watercolor effects, intricate illustrations, and gradients are all possible. You can use millions of colors without increasing cost. This is ideal for artistic, narrative, or highly detailed designs on accessories.

What About Cost, MOQ, and Lead Time?

| These practical factors often dictate the choice for businesses. | Factor | Jacquard Weaving | Fabric Printing (Digital) |

|---|---|---|---|

| Setup Cost | Very High (loom programming) | Relatively Low (digital file setup) | |

| Unit Cost | Higher, but decreases with volume | Lower, especially for small runs | |

| MOQ | High (often 500-1000+ meters per design) | Very Low (can be as little as 1-10 meters for sampling) | |

| Production Speed | Slower (weaving is a linear process) | Very Fast (once printing begins) | |

| Best For | Established lines, luxury goods, high-volume seasonal basics | Fast fashion, test marketing, custom/niche products, trend-driven items |

How to Choose the Right Technique for Your Accessory?

So, how do you decide? It comes down to asking the right questions about your specific product. What is the desired hand-feel? What is the price point? How quickly do you need it? How complex is the design? A reliable partner like Shanghai Fumao Clothing can help you navigate this decision based on your sample and goals.

The choice isn't always either/or. Sometimes, a combination can be stunning—for example, a jacquard-woven base fabric with a delicate printed overlay for metallic accents. This level of innovation requires a supplier with strong technical integration.

When Should You Definitely Choose Jacquard?

Choose jacquard when:

- Texture and Luxury are Key: For products like winter wool scarves, elegant shawls, or high-end hat bands where a substantial, textured feel defines quality.

- Reversibility is a Feature: For scarves and wraps designed to be worn in multiple ways, showing different sides.

- You Need Classic Durability: For items like belt straps or bag accents that will undergo friction and need the pattern to last the lifetime of the product.

- You Have Large, Forecasted Orders: The high MOQ and setup cost are justified by volume, leading to a beautiful product at a good value.

When is Printing the Undisputed Best Choice?

Choose printing when:

- Design Complexity is High: Your design has photorealism, sketches, gradients, or more than 8-10 colors.

- You are Testing the Market or Have Low Volume: You want to launch a small, niche line without committing to large MOQs. Digital printing is perfect for made-to-order or limited-edition accessory runs.

- Speed to Market is Critical: You need to catch a fast trend. From final art to finished product, printing is much faster.

- You Want a Specific Fabric Hand-Feel: You love the drape of a lightweight silk twill or viscose challis and want to add your pattern to it, which would be impossible to achieve through weaving that specific base.

Conclusion

Jacquard and print are two fundamentally different languages of textile design. Jacquard speaks in structure, texture, and enduring elegance, woven into the very soul of the fabric. Print speaks in color, artistry, and limitless expression, painted onto the fabric's surface. There is no "better" technique—only the right technique for your specific design vision, product requirements, and business model.

By understanding their core differences in production, cost, and final appearance, you empower yourself to make informed sourcing decisions. This knowledge allows you to develop accessories that not only look beautiful but also perform and feel exactly as intended, building trust with your customers and strengthening your brand.

Ready to bring your next patterned accessory concept to life with the perfect production technique? Contact our Business Director Elaine at Shanghai Fumao Clothing. Our team of experts can guide you from concept to sample, helping you choose between jacquard, print, or even a combination to create a standout product. Email her at: elaine@fumaoclothing.com to start your next project.