Sourcing accessories that feature LED lights may sound exciting, but it often comes with unique challenges that many buyers overlook. From quality inconsistencies to supply chain delays, many fashion and retail buyers struggle to balance cost, durability, and performance. These problems can directly impact their brand reputation if not handled carefully.

The main challenges in sourcing LED accessories involve quality control, compliance with international certifications, supply chain timeliness, and managing pricing pressures while keeping designs fresh and reliable.

For buyers in the U.S. and Europe, where competition is fierce, ensuring a reliable supply of high-quality LED-integrated products requires careful supplier selection and proactive management. Let me share what I have learned as a manufacturer in this field.

Quality Control Issues in LED Accessories

When buyers source LED accessories, quality control is one of the first major challenges. LED technology may be small, but it brings higher risks compared to regular fabric or plastic accessories. Poor soldering, weak battery cases, and inconsistent brightness often create customer complaints.

Quality problems in LED accessories come from unstable components, poor assembly practices, and inconsistent testing methods.

Why is durability often compromised?

Durability is the most common complaint. Accessories like LED hair bands or caps often fail after short use. Batteries may run out quickly, wires may break, and moisture can damage the circuit. Unlike regular products, LED versions need extra protection to keep performance consistent. Without strong supplier-side testing, many products don’t meet real-life usage needs.

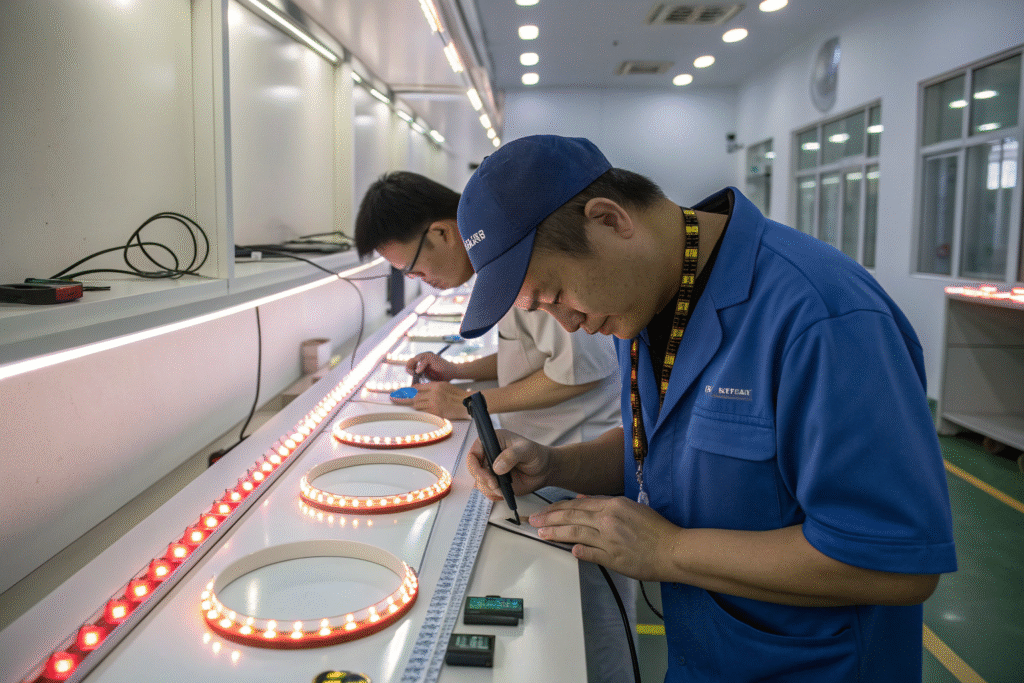

How can manufacturers improve testing?

The solution lies in better testing standards. Suppliers must use drop tests, water resistance tests, and repeated lighting cycles to simulate actual usage. Reliable suppliers also use ISO-certified processes. Buyers should request detailed reports before bulk orders. This helps reduce returns and protects brand reputation.

Compliance and Safety Certifications

Another big challenge is compliance. Accessories with LED parts fall under electronic product regulations in many countries. This means that a supplier who can make a good-looking product is not enough. They must also meet international certification standards.

LED accessories must comply with safety, environmental, and battery transport certifications before entering Europe or the U.S. market.

What certifications are required for U.S. and Europe?

In the U.S., buyers often need FCC approval for electronic components, while in Europe CE marking is mandatory. Additionally, environmental standards like RoHS compliance ensure that LED components are free of harmful materials. Without these, customs clearance becomes difficult and costly.

Why do many suppliers fail certification tests?

Many small suppliers skip certification because of cost. They use uncertified LED chips or batteries, which reduces price but increases risk. Products may be blocked at customs or recalled after entering the market. Buyers should always request documents and verify them with official databases. Working with certified manufacturers saves both time and money in the long run.

Supply Chain and Delivery Delays

Even if quality and compliance are ensured, the supply chain itself brings difficulties. LED accessories often involve mixed materials, such as fabrics, plastics, and electronic chips. Each component may come from different suppliers. Any delay in one part can slow down the entire order.

Supply chain delays in LED accessories often come from electronic component shortages, customs checks, and complex shipping requirements for batteries.

How do battery shipping rules affect delivery?

Lithium batteries are classified as dangerous goods in international logistics. Airlines and shipping companies require special handling and documents. For example, IATA regulations restrict how batteries can be packed and shipped. This often leads to longer delivery times or unexpected charges.

Can nearshoring or faster routes solve the problem?

Some buyers look for nearshoring in Mexico or Eastern Europe. But the cost is often higher, and the product range is limited. The best solution is working with an experienced supplier in China who has a proven logistics team. They know how to prepare the right paperwork and book faster sailing schedules. This helps keep products on shelves in time for seasonal sales.

Balancing Cost and Design Innovation

The last major challenge is finding the right balance between cost and design. Buyers want accessories that look trendy and perform well. But LED parts add to the price. Many brands struggle to decide between lowering quality to save cost or investing more to stand out in the market.

Balancing cost and design in LED accessories requires choosing suppliers who can innovate while controlling expenses.

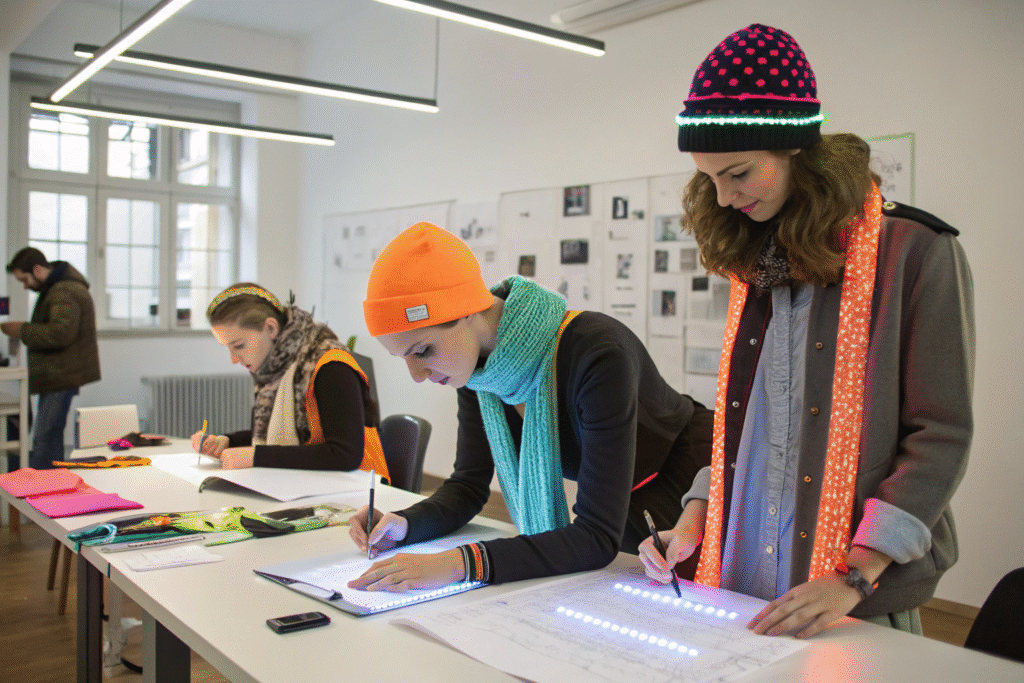

Why is design innovation important for LED products?

LED accessories succeed when they feel fresh. A glowing fashion scarf or party hat attracts customers only if the design is stylish and practical. Without innovation, products become gimmicks that fade quickly. This is why working with a supplier with an in-house design team gives a strong advantage.

How can cost efficiency be maintained?

The answer is scale and smart sourcing. Ordering in higher volumes reduces unit costs. Choosing suppliers in regions like Zhejiang, where both textiles and electronics are available, also lowers logistics costs. Buyers should also negotiate flexible payment terms to manage cash flow. This ensures the brand can introduce LED products without taking on excessive financial risk.

Conclusion

Sourcing accessories with LED lights brings more challenges than standard products. Quality control, compliance, logistics, and cost balance all play big roles in making or breaking a sourcing project. By working with the right partners who understand these areas, buyers can avoid costly mistakes and build stronger product lines.

At AceAccessory, we specialize in producing high-quality fashion accessories, including LED-integrated designs. Our modern factory in Zhejiang, China, has professional designers, strict quality control, and experienced project managers to help you overcome these challenges. If you want to develop your own accessory line with confidence, you can contact our Business Director Elaine at elaine@fumaoclothing.com for cooperation.