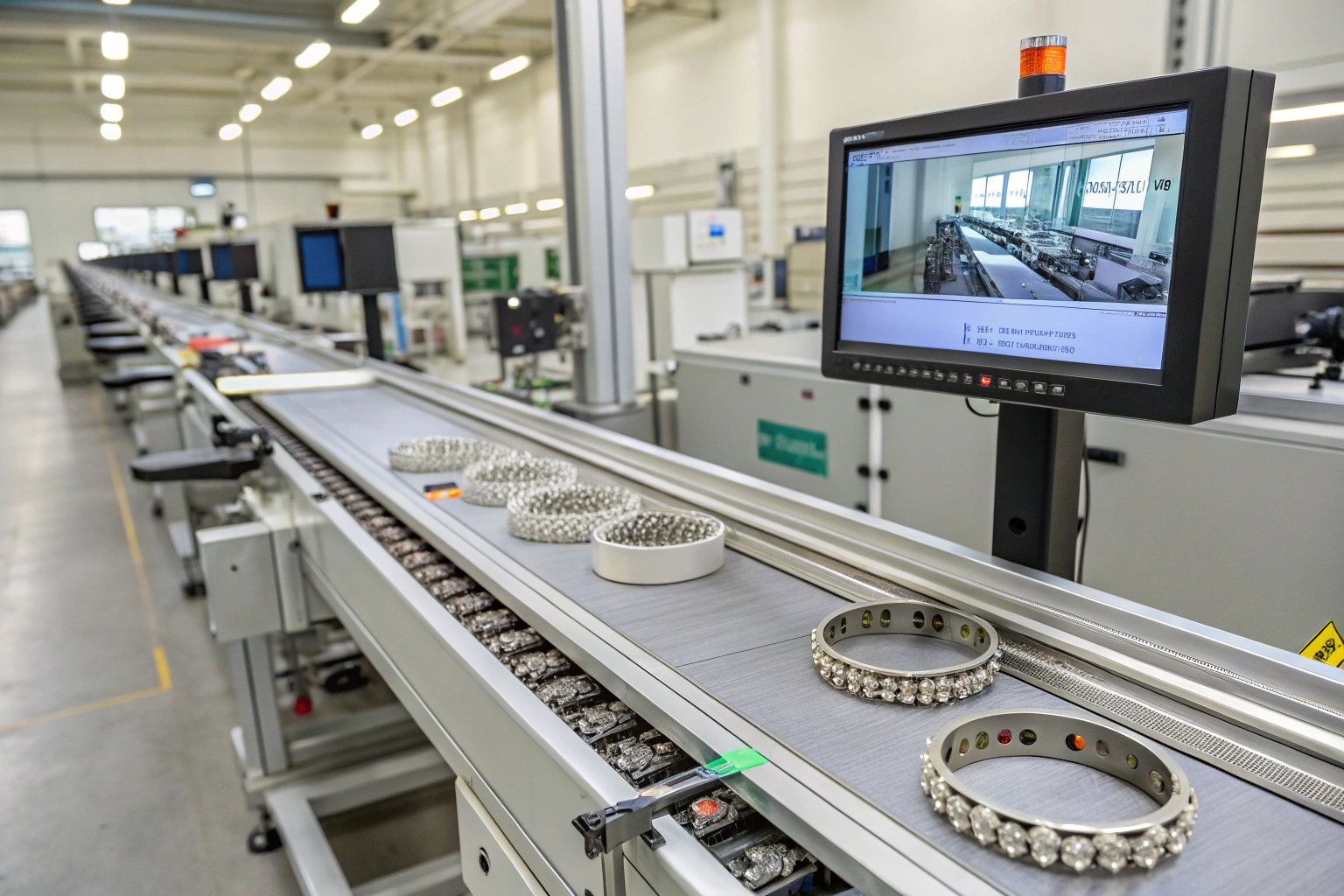

Computer vision technology has revolutionized quality control in bracelet manufacturing, offering precision, speed, and consistency that far surpass traditional manual inspection methods. At AceAccessory, our implementation of computer vision systems has transformed our bracelet quality assurance processes, delivering remarkable improvements in detection accuracy and operational efficiency.

Computer vision offers significant advantages in bracelet quality inspection including superior detection accuracy, consistent inspection standards, high-speed processing capabilities, comprehensive data analytics, and reduced labor costs. These systems can identify minute defects invisible to the human eye while maintaining unwavering inspection standards 24/7.

The integration of computer vision represents a fundamental shift from subjective visual assessment to objective, data-driven quality verification. Let's explore the specific advantages this technology brings to bracelet quality inspection.

How does computer vision achieve superior detection accuracy?

Computer vision systems leverage advanced imaging technology and machine learning algorithms to identify defects with precision that significantly exceeds human visual capabilities.

Computer vision achieves superior detection accuracy through high-resolution imaging, sophisticated pattern recognition, multi-angle inspection, and machine learning algorithms that continuously improve defect detection capabilities.

What types of defects can computer vision identify in bracelets?

Comprehensive defect detection covers both obvious and subtle quality issues. Our systems reliably identify:

- Surface imperfections including scratches, dents, pits, and discoloration

- Dimensional inaccuracies detecting size variations as small as 0.1mm

- Assembly defects identifying missing components, loose connections, or misalignments

- Material flaws spotting inconsistencies in gemstones, metals, and other materials

- Finishing issues detecting problems with plating, polishing, or coating uniformity

Our computer vision systems have achieved 99.7% detection accuracy for critical defects, compared to 85-90% with manual inspection. The technology particularly excels at identifying subtle color variations in gemstone settings and microscopic cracks in metal components that human inspectors frequently miss.

How does machine learning enhance detection capabilities?

Continuous improvement algorithms make computer vision systems increasingly effective over time. Key enhancements include:

- Adaptive learning from verified defect examples to recognize new flaw patterns

- Anomaly detection identifying previously unseen defect types based on deviation from normal patterns

- Contextual understanding recognizing that certain "defects" may be acceptable in specific design contexts

- False positive reduction learning to distinguish between actual defects and harmless variations

Our systems have reduced false positives by 78% through continuous learning, while simultaneously expanding the range of detectable defects by 45% over 18 months of operation.

How does computer vision ensure inspection consistency?

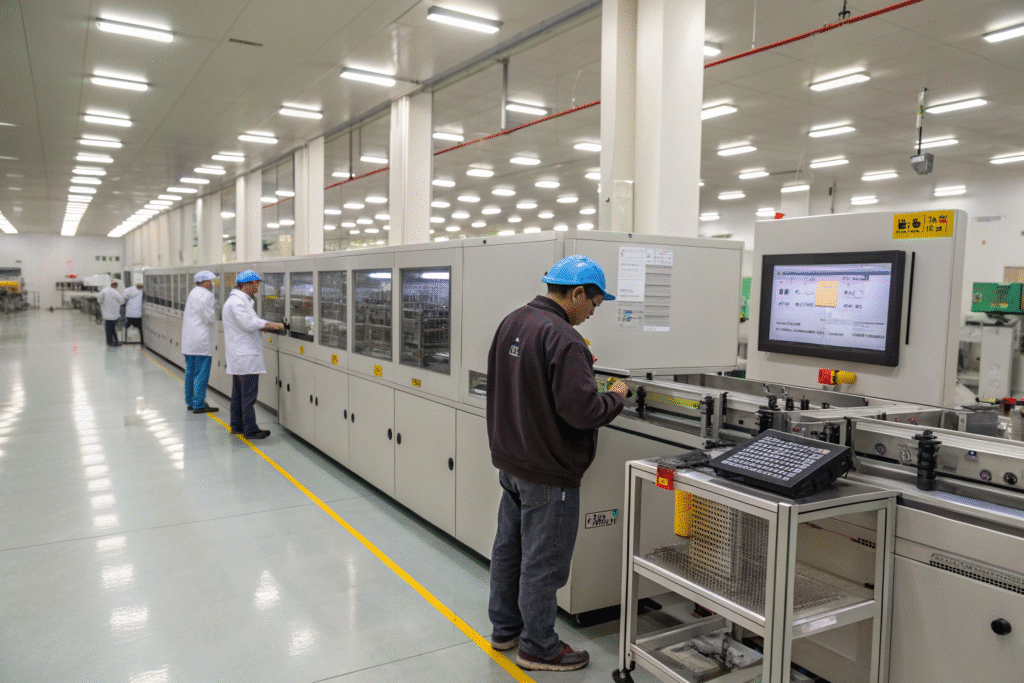

Unlike human inspectors who experience fatigue, distraction, and subjective judgment variations, computer vision systems maintain identical inspection standards continuously.

Computer vision ensures inspection consistency through unwavering assessment criteria, elimination of human factors, continuous operation capability, and standardized evaluation metrics that provide reliable quality assessment regardless of time, volume, or environmental conditions.

What factors contribute to computer vision's unwavering standards?

Stable operational parameters create consistent inspection outcomes. Key factors include:

- Fixed lighting conditions ensuring identical illumination for every inspection

- Consistent camera positioning maintaining identical viewing angles and distances

- Unchanging assessment algorithms applying identical criteria to every bracelet

- Elimination of fatigue effects operating with identical accuracy regardless of duration

- Removal of subjective judgment basing decisions solely on predefined parameters

This consistency has eliminated the quality variations we previously experienced between different inspectors and shifts. Our quality rejection rates now show less than 0.5% variation across all production batches, compared to 8-12% variation with manual inspection.

How does computer vision handle high-volume inspection?

Scalable processing capability maintains quality standards regardless of quantity. Our systems provide:

- 24/7 operation without degradation in performance or attention

- Simultaneous multi-point inspection examining multiple bracelets concurrently

- Real-time processing completing inspections in seconds rather than minutes

- Automated sorting immediately categorizing products based on quality assessment

The table below shows inspection performance comparisons:

| Inspection Metric | Manual Inspection | Computer Vision | Improvement |

|---|---|---|---|

| Inspection Speed | 15-20 seconds per bracelet | 2-3 seconds per bracelet | 85% faster |

| Consistency Variation | 8-12% between inspectors | <0.5% variation | 94% more consistent |

| Maximum Daily Capacity | 1,200-1,500 bracelets | 12,000-15,000 bracelets | 10x capacity |

| Defect Detection Accuracy | 85-90% | 99.2-99.7% | 10-15% improvement |

These improvements have allowed us to increase production volume by 300% while simultaneously improving quality standards.

What operational efficiencies does computer vision create?

Beyond quality improvements, computer vision delivers significant operational benefits through faster processing, reduced costs, and valuable data insights that enhance overall manufacturing efficiency.

Computer vision creates operational efficiencies through automated inspection processes, reduced labor requirements, faster throughput, comprehensive data collection, and preventive quality management that optimizes manufacturing operations.

How does computer vision reduce inspection costs?

Significant cost savings result from multiple efficiency improvements. Key benefits include:

- Labor cost reduction decreasing manual inspection requirements by 70-80%

- Rework minimization identifying defects early before value-added processes

- Waste reduction preventing material waste through early defect detection

- Training elimination removing need for extensive inspector training programs

- Error cost avoidance preventing shipping of defective products to customers

Our computer vision implementation achieved full ROI within 14 months through these cost savings, while simultaneously improving our quality reputation and reducing customer returns by 62%.

How does computer vision enhance production throughput?

Accelerated inspection processes remove quality control bottlenecks. Efficiency improvements include:

- Non-contact inspection allowing continuous movement during assessment

- Parallel processing examining multiple quality parameters simultaneously

- Immediate feedback providing real-time data to production equipment

- Automated sorting eliminating manual handling after inspection

- Integrated workflows seamlessly connecting inspection with subsequent processes

These throughput enhancements have reduced our total manufacturing cycle time by 28% by eliminating the queuing and handling delays associated with manual inspection stations. The continuous flow has been particularly valuable for high-volume bracelet collections with tight production schedules.

How does computer vision enable data-driven quality management?

Computer vision systems generate comprehensive quality data that provides unprecedented insights into manufacturing processes, defect patterns, and improvement opportunities.

Computer vision enables data-driven quality management through detailed defect recording, statistical trend analysis, correlation identification, predictive quality forecasting, and continuous improvement tracking that transforms quality control from reactive to proactive.

What quality insights does computer vision data provide?

Comprehensive quality intelligence reveals patterns and opportunities invisible through manual methods. Valuable insights include:

- Defect pattern analysis identifying when and where specific defects occur

- Process parameter correlation linking manufacturing settings with quality outcomes

- Equipment performance impact understanding how machine condition affects quality

- Material quality assessment evaluating incoming material consistency

- Seasonal variation tracking detecting environmental impacts on quality

These insights have enabled us to reduce our overall defect rate by 58% through targeted process improvements identified by the computer vision data analysis. The most valuable revelation was identifying that a specific cleaning compound residue was causing adhesion issues in decorated bracelets—a problem that had persisted for months without identification through traditional methods.

How does computer vision support preventive quality management?

Predictive quality capabilities enable proactive defect prevention. Advanced applications include:

- Early warning systems flagging conditions that typically lead to quality issues

- Trend-based interventions initiating process adjustments based on quality drift patterns

- Equipment maintenance triggers scheduling maintenance based on quality impact rather than time

- Supplier quality feedback providing specific data to material suppliers for improvements

- Design modification guidance identifying design elements prone to manufacturing defects

This preventive approach has reduced customer quality complaints by 73% and decreased the cost of quality (including prevention, appraisal, and failure costs) by 41% compared to our previous reactive quality management system.

How does computer vision handle complex bracelet designs?

Modern bracelet designs often incorporate intricate patterns, mixed materials, and detailed craftsmanship that present challenges for traditional inspection methods—challenges that computer vision is uniquely equipped to address.

Computer vision handles complex bracelet designs through advanced pattern recognition, 3D imaging capabilities, multi-spectral analysis, and adaptive learning algorithms that accommodate intricate details and varied materials.

How does computer vision adapt to diverse bracelet styles?

Flexible inspection protocols accommodate design variations without reprogramming. Key capabilities include:

- Template matching comparing products against reference designs with tolerance for acceptable variations

- Feature-based inspection examining specific design elements rather than complete pattern matching

- Adaptive thresholding adjusting sensitivity based on material properties and design complexity

- Multi-camera systems capturing different angles and details simultaneously

- Custom defect definitions allowing specific quality criteria for different design collections

This adaptability has been crucial for our custom and limited-edition bracelet collections, where each design may have unique quality requirements. The systems can be quickly configured for new designs while maintaining rigorous inspection standards.

How does computer vision inspect intricate details and materials?

Specialized imaging techniques address challenging inspection requirements. Advanced methods include:

- Macro photography capturing extreme close-ups of small details and settings

- 3D profilometry measuring surface contours and depth variations

- Multi-spectral imaging detecting material variations invisible in standard visible light

- Polarized light analysis identifying stress patterns in transparent materials

- High-speed video capturing dynamic aspects like clasp operation and flexibility

These specialized capabilities have been particularly valuable for luxury bracelets with intricate metalwork, precise gemstone settings, and complex mechanisms. The systems can verify that each tiny component meets specifications while maintaining the aesthetic integrity of the design.

Conclusion

Computer vision offers transformative advantages in bracelet quality inspection, delivering superior accuracy, unwavering consistency, operational efficiencies, data-driven insights, and adaptability to complex designs that collectively revolutionize quality assurance processes. The technology addresses both obvious and subtle quality issues while providing the comprehensive data needed for continuous improvement.

The implementation of computer vision represents a significant advancement over traditional inspection methods, enabling manufacturers to achieve quality standards previously impossible through manual processes alone. The combination of precision, speed, and intelligence creates a powerful quality management tool that enhances both product excellence and manufacturing efficiency.

As computer vision technology continues to advance and become more accessible, its role in bracelet manufacturing and quality assurance will likely expand, offering even greater capabilities for defect detection, process optimization, and quality management. Manufacturers who embrace this technology strategically will gain significant competitive advantages in quality, efficiency, and customer satisfaction.

If you're considering implementing computer vision for bracelet quality inspection and would like to benefit from our experience in developing and optimizing these systems, we invite you to contact our Business Director, Elaine. She can guide you through our implementation approach and help you develop a computer vision strategy tailored to your specific quality requirements. Reach her at: elaine@fumaoclothing.com.