The headband manufacturing process has traditionally relied on manual design, pattern making, and production planning—methods that often result in material waste, design limitations, and inconsistent quality. As consumer demand for personalized, sustainable, and quickly delivered accessories grows, traditional approaches struggle to keep pace with market expectations while maintaining profitability.

Artificial intelligence transforms headband manufacturing by optimizing design creation, automating production processes, personalizing products at scale, and predicting market trends with unprecedented accuracy.From AI-generated designs that reflect emerging fashion trends to intelligent manufacturing systems that minimize waste, AI technologies are revolutionizing how headbands are conceived, produced, and brought to market.

Let's explore the practical applications of AI across the headband manufacturing workflow, from initial concept to finished product.

How can AI generate and optimize headband designs?

Traditional headband design relies heavily on designer intuition and manual iteration, a process that can be time-consuming and may miss emerging trends or optimization opportunities. Designers typically create limited variations due to time constraints, potentially overlooking innovative combinations that would resonate with consumers.

AI design tools analyze vast amounts of fashion data, consumer preferences, and historical sales information to generate design options that balance aesthetic appeal with commercial viability and manufacturing efficiency.

What data sources fuel AI design generation?

AI design systems process diverse data streams including social media fashion trends, historical sales data, color trend forecasts, and even cultural events that influence fashion preferences. Our AI analyzes thousands of fashion images weekly, identifying emerging patterns in colors, materials, and styles specifically relevant to headwear. This trend analysis has helped us identify the rising popularity of wider, fabric-wrapped headbands three months before they reached peak demand, allowing us to lead the market rather than follow it.

How does AI optimize designs for manufacturing?

Generative design algorithms create hundreds of design variations that meet specified aesthetic criteria while optimizing for material usage, production complexity, and structural integrity. For our plastic headband line, the AI generated designs that used 22% less material while maintaining strength and comfort, significantly reducing both material costs and environmental impact. This design optimization has been particularly valuable for creating headbands that are both fashionable and practical to manufacture at scale.

How can AI improve material selection and usage?

Material costs represent a significant portion of headband production expenses, and traditional material selection often relies on established supplier relationships and past experiences rather than data-driven optimization. Similarly, manual pattern nesting and cutting frequently results in substantial material waste, especially with expensive fabrics and specialty materials.

AI systems analyze material properties, costs, availability, and sustainability metrics to recommend optimal materials while ensuring maximum utilization through intelligent cutting patterns.

How does AI optimize material selection for different headband types?

Machine learning algorithms evaluate material characteristics against design requirements, consumer preferences, and cost constraints to recommend optimal materials for each headband style. Our AI system identified that a specific blend of recycled polyester and spandex provided better performance and sustainability credentials than our traditional materials for sport headbands, at 18% lower cost. This intelligent material selection has improved our product quality while reducing material costs by approximately 15% across our collection.

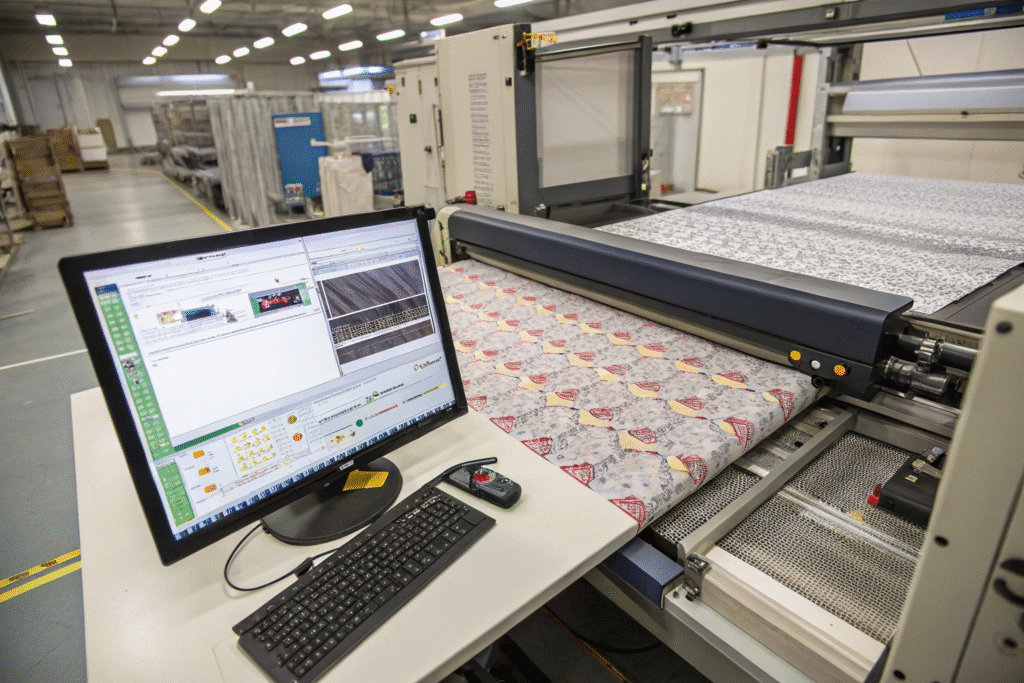

How can AI minimize material waste during production?

Computer vision and AI nesting algorithms analyze material rolls for defects and irregularities, then calculate optimal cutting patterns that maximize usable output. Our implementation of AI-powered cutting for fabric headbands has achieved 94% material utilization compared to the 70-75% typical of manual methods. This waste reduction translates to significant cost savings and environmental benefits, particularly important as consumers increasingly value sustainable manufacturing practices.

How can AI enhance production planning and quality control?

Headband manufacturing involves multiple production stages—from material preparation and component fabrication to assembly and finishing. Traditional planning often results in bottlenecks, inventory imbalances, and quality inconsistencies that increase costs and delay deliveries.

AI systems transform production planning through predictive analytics and enhance quality control through computer vision systems that exceed human inspection capabilities.

How does AI optimize production scheduling?

Predictive analytics algorithms analyze order patterns, production capacity, and material availability to create optimized production schedules that minimize changeover time and balance workload across equipment and personnel. Our AI production planning system has reduced machine idle time by 35% and decreased order lead times from 3 weeks to 10 days by identifying and preventing potential bottlenecks before they occur. This efficient scheduling has been particularly valuable for handling the seasonal demand spikes that characterize fashion accessories.

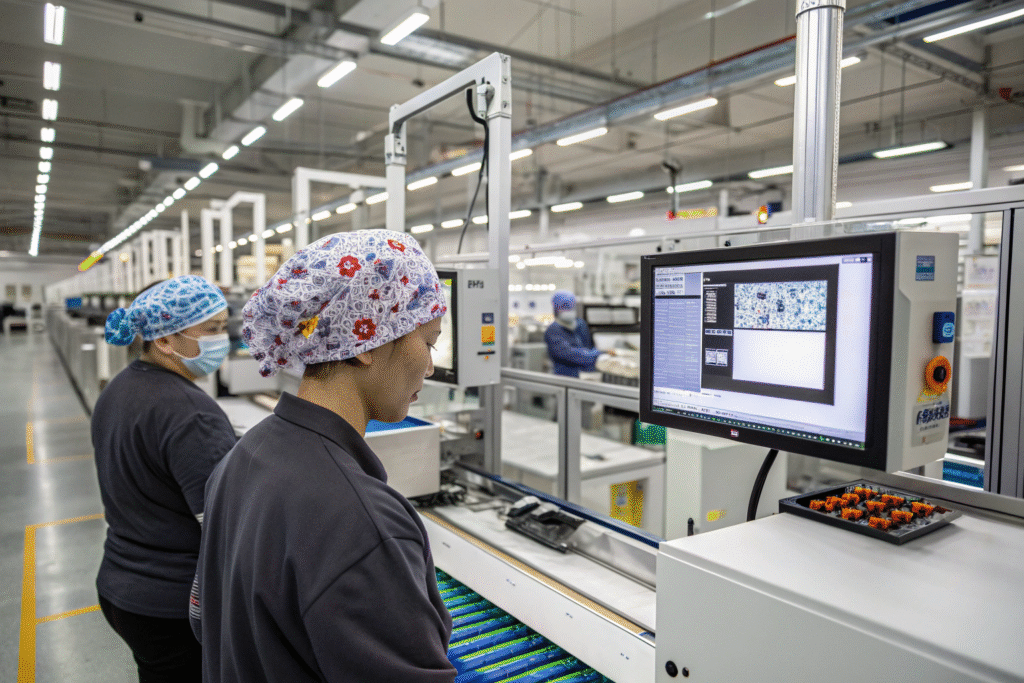

How can AI improve headband quality control?

Computer vision inspection systems trained on thousands of images can identify defects that human inspectors might miss, including subtle color variations, stitching inconsistencies, and structural flaws. Our AI quality control system for embellished headbands detects misplaced decorative elements, glue residue, and fabric flaws with 99.7% accuracy, compared to approximately 92% for human inspection. This automated quality assurance has reduced customer returns by 64% while freeing human quality controllers to focus on more complex evaluation tasks.

How can AI enable personalization at scale?

Mass customization has been largely impractical in traditional headband manufacturing due to the setup costs and production complexities involved in creating unique items. Most manufacturers offer limited personalization options, if any, constraining consumer choice and missing revenue opportunities.

AI systems make true personalization economically viable by automating the translation of customer preferences into manufacturing instructions and optimizing production workflows for one-of-a-kind items.

How can AI facilitate customer-driven design?

AI design interfaces allow customers to create custom headbands by selecting colors, patterns, widths, and decorative elements, with the system ensuring designs are manufacturable and providing instant previews. Our customization platform uses AI to guide customers toward aesthetically coherent combinations while preventing technically unfeasible designs. This guided customization has increased our average order value by 28% while creating a distinctive market position in personalized accessories.

How does AI manage personalized production efficiently?

AI production management systems automatically group custom orders with similar characteristics to minimize material changes and machine setup time. Our system analyzes incoming custom orders and batches them for production based on material type, color, and manufacturing processes required. This intelligent batching allows us to produce personalized headbands with the same efficiency as small-batch standardized production, making customization economically viable without minimum order requirements.

Conclusion

Artificial intelligence is transforming headband manufacturing from a traditional craft-based process to a highly efficient, data-driven operation that balances aesthetic creativity with manufacturing optimization. By leveraging AI across design, material selection, production planning, quality control, and personalization, manufacturers can create better products faster, with less waste, and with greater responsiveness to market demands.

As AI technologies continue to advance and become more accessible, their integration into headband manufacturing will shift from competitive advantage to industry standard—enabling manufacturers to meet evolving consumer expectations for sustainability, personalization, and rapid delivery while maintaining profitability.

If you're interested in implementing AI solutions for your headband production or want to partner with a manufacturer that leverages artificial intelligence throughout the manufacturing process, we invite you to contact our Business Director, Elaine. She can discuss our AI capabilities and how they can enhance your headband collections. Reach her at: elaine@fumaoclothing.com.