Hair accessory manufacturing relies on specialized equipment—injection molding machines for plastic clips, metal stamping presses for components, automated assembly systems, and precision packaging lines. Unexpected equipment failures in this high-volume industry cause massive production disruptions, missed deadlines, and costly emergency repairs. Traditional maintenance scheduling, whether time-based or reactive, fails to account for actual equipment conditions, usage patterns, and early failure indicators.

AI transforms preventive maintenance scheduling in hair accessory manufacturing by analyzing equipment sensor data, production parameters, and historical failure patterns to predict maintenance needs with unprecedented accuracy. This approach shifts maintenance from fixed schedules or emergency responses to precisely timed interventions that prevent failures while minimizing downtime and extending equipment lifespan.

Let's explore the practical implementation of AI-driven predictive maintenance across different types of hair accessory manufacturing equipment.

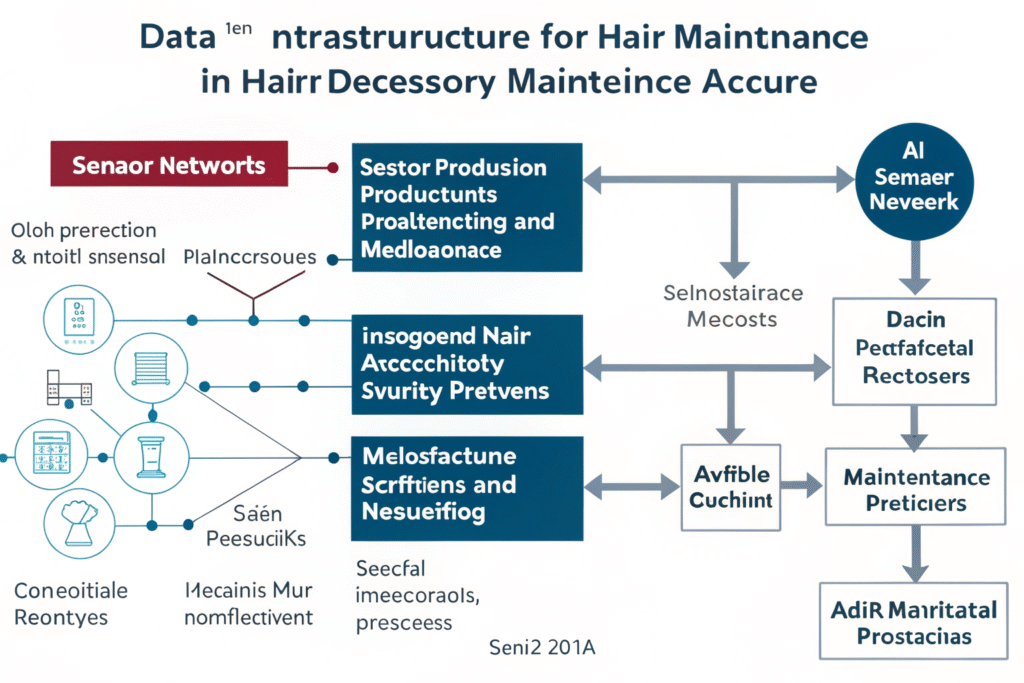

What data infrastructure supports AI-powered maintenance scheduling?

Effective AI maintenance scheduling requires comprehensive data collection, integration, and processing capabilities. Traditional maintenance systems often rely on limited data points—mainly equipment runtime and basic error codes—which provide insufficient information for accurate failure prediction. The foundation of AI-driven maintenance is a robust data ecosystem that captures the multitude of factors influencing equipment health.

Building this infrastructure requires both hardware sensors and software integration across the manufacturing environment.

What sensor data is most valuable for maintenance prediction?

Multi-dimensional monitoring captures vibration patterns, temperature fluctuations, power consumption, acoustic emissions, and production quality metrics that collectively indicate equipment health. Our implementation on plastic injection molding machines for hair clip production monitors 47 different parameters, with vibration analysis proving particularly predictive of screw and barrel wear 2-3 weeks before failure becomes apparent through product quality issues. This comprehensive monitoring has enabled us to schedule maintenance during planned production gaps rather than reacting to unexpected failures.

How does equipment integration enhance predictive capabilities?

Machine control system data combined with external sensors provides context for equipment behavior, distinguishing between normal operational variations and early failure indicators. Our integration with CNC machines for metal hair accessory components correlates tool path accuracy with motor current draw, identifying bearing wear through subtle changes in power consumption patterns. This contextual analysis has reduced false positive maintenance alerts by 73% compared to systems using only external sensor data.

How do machine learning algorithms predict maintenance needs?

Traditional maintenance scheduling relies on fixed time intervals or usage thresholds that cannot account for variations in operating conditions, material properties, or subtle equipment degradation. Statistical methods often miss complex, non-linear relationships between multiple variables that precede equipment failures. Machine learning algorithms excel at identifying these complex patterns across diverse data sources.

The most effective implementations use ensemble approaches that combine multiple algorithms for different failure modes and equipment types.

What types of AI models are most effective for maintenance prediction?

Anomaly detection algorithms identify unusual patterns in equipment behavior that may indicate emerging issues, while regression models predict remaining useful life based on current operating conditions and historical failure data. Our system uses gradient boosting machines for predicting mechanical failures in automated assembly equipment and recurrent neural networks for detecting gradual performance degradation in continuous production systems. This algorithm specialization has improved our prediction accuracy from 68% with traditional statistical methods to 94% with our current AI implementation.

How does the system learn from new maintenance events?

Continuous model retraining incorporates data from completed maintenance activities, equipment repairs, and unexpected failures to refine prediction accuracy over time. Our system automatically updates its models after each maintenance event, comparing predicted issues with actual findings and adjusting its algorithms accordingly. This learning capability has been particularly valuable for new equipment types where initial prediction models lack sufficient historical data for high accuracy.

How can AI maintenance be implemented across different equipment types?

Hair accessory manufacturing involves diverse equipment with different failure modes, criticality levels, and maintenance requirements. A one-size-fits-all approach to predictive maintenance would miss equipment-specific failure patterns and maintenance optimization opportunities. Successful implementation requires tailored approaches for different equipment categories.

The most effective systems recognize that injection molding machines, metal stamping presses, and automated assembly systems have different maintenance needs and failure indicators.

How does AI maintenance differ for plastic injection molding equipment?

Material-specific wear patterns require monitoring of screw and barrel condition, heater performance, and hydraulic system integrity that affect hair clip quality and production efficiency. Our AI system for injection molding machines predicts screw wear based on melt pressure patterns, motor current signatures, and product quality metrics, scheduling maintenance 200-300 hours before failure typically occurs. This precision timing has reduced unplanned downtime for our clip production lines by 82% while extending screw and barrel lifespan by 37% through earlier intervention.

What unique maintenance challenges does metal stamping equipment present?

Impact-related fatigue and die wear represent the primary maintenance concerns for metal hair accessory components, requiring different monitoring approaches than continuous process equipment. Our system for stamping presses analyzes vibration patterns during the impact cycle, tonnage curves, and part ejection forces to predict die wear and press frame stress. This impact analysis has reduced die-related production interruptions by 76% and prevented two potential press frame failures that would have required weeks of repairs.

How can AI-optimized scheduling maximize equipment availability?

Predicting maintenance needs provides limited value if scheduling doesn't optimize around production priorities, resource availability, and operational constraints. Traditional maintenance scheduling often occurs independently from production planning, creating conflicts between maintenance needs and production demands. The greatest benefits come from integrated systems that balance maintenance requirements with operational objectives.

AI-driven scheduling transforms maintenance from a disruptive necessity to an optimized component of overall operations.

How does AI balance maintenance needs with production requirements?

Multi-objective optimization algorithms consider equipment criticality, maintenance urgency, production schedules, and resource availability to recommend optimal maintenance timing. Our system evaluates hundreds of potential scheduling scenarios to identify windows that minimize production impact while addressing maintenance needs before they become critical. This intelligent scheduling has increased our overall equipment effectiveness (OEE) by 14% by reducing both unplanned downtime and the production disruption of planned maintenance.

How does predictive maintenance integrate with inventory management?

Spare parts forecasting uses maintenance predictions to ensure required components are available when needed without maintaining excessive inventory. Our system automatically generates spare parts orders based on maintenance predictions, considering supplier lead times and criticality of each component. This integrated planning has reduced our spare parts inventory by 32% while completely eliminating production delays due to unavailable maintenance components.

Conclusion

AI-driven preventive maintenance scheduling represents a fundamental shift in how hair accessory manufacturers manage equipment reliability, moving from reactive repairs or fixed intervals to precisely timed interventions based on actual equipment conditions. By building the necessary data infrastructure, implementing appropriate machine learning algorithms, adapting approaches to different equipment types, and integrating maintenance with production scheduling, manufacturers can achieve unprecedented levels of equipment availability and reliability.

The transformation requires significant investment in sensors, data systems, and analytical capabilities, but the returns in reduced downtime, lower repair costs, extended equipment life, and improved production consistency justify the commitment. As the technology continues to advance and become more accessible, AI-powered maintenance will evolve from competitive advantage to essential capability for any hair accessory manufacturer seeking operational excellence.

If you're interested in implementing AI-powered maintenance scheduling for your hair accessory manufacturing or want to partner with a manufacturer that has advanced predictive maintenance capabilities, we invite you to contact our Business Director, Elaine. She can discuss our AI maintenance approach and how it delivers superior equipment reliability and production consistency. Reach her at: elaine@fumaoclothing.com.