Material costs typically represent 40-60% of total production expenses in fashion accessory manufacturing, yet traditional material planning often relies on historical patterns and manual calculations. This approach leads to significant fabric waste, suboptimal material selection, and missed opportunities for cost savings through smarter material utilization. The complexity of optimizing material usage across diverse accessory types—from leather belts to silk scarves to metal jewelry—makes manual optimization nearly impossible.

AI transforms material optimization in fashion accessory manufacturing by analyzing design specifications, production patterns, and material properties to minimize waste, reduce costs, and enhance sustainability.Through machine learning algorithms, computer vision, and predictive analytics, AI systems identify optimal cutting patterns, recommend material substitutions, and predict exact material requirements with unprecedented accuracy.

Let's explore the specific AI applications that are revolutionizing how accessory manufacturers approach material selection, utilization, and waste reduction.

How does AI optimize material cutting and pattern utilization?

Traditional material cutting for accessories relies on manual pattern placement and operator experience, often resulting in substantial waste—particularly with expensive materials like genuine leather, silk, or specialty fabrics. Even experienced workers cannot consistently achieve the optimal layout that maximizes material usage across variable material defects and irregular shapes.

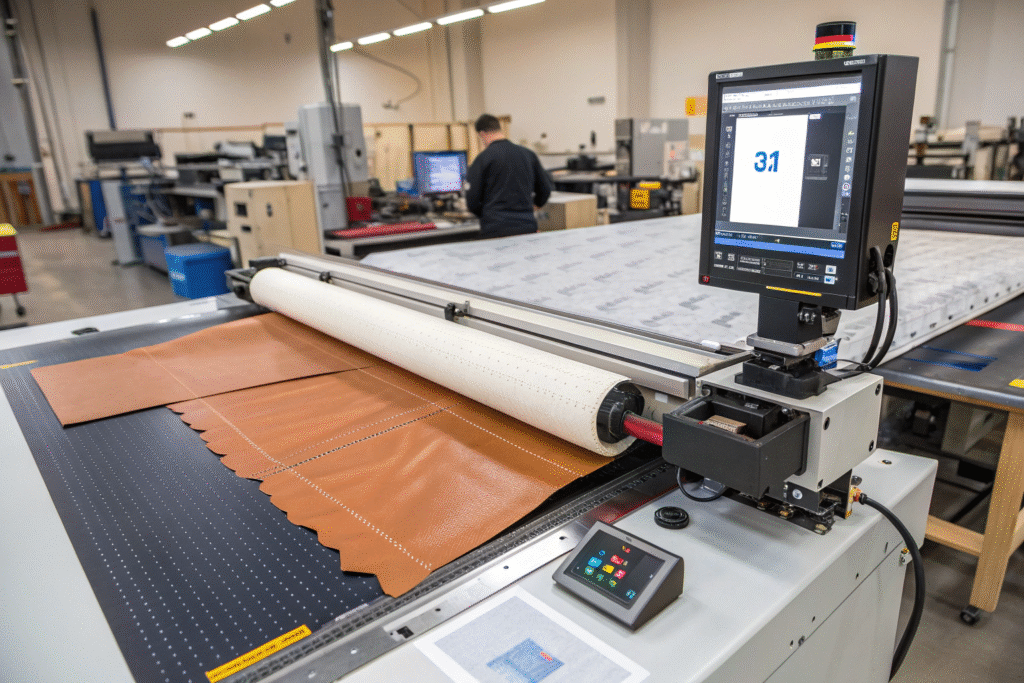

AI-powered nesting and cutting optimization algorithms analyze material characteristics and design requirements to achieve near-perfect material utilization, significantly reducing waste and cost.

What makes AI cutting optimization superior to manual methods?

AI nesting algorithms process thousands of potential pattern arrangements in minutes, considering material constraints like natural defects, grain direction, and stretch characteristics. For leather belt production, our AI system analyzes each hide's unique shape and flaw distribution before generating cutting patterns that achieve 94% material utilization—compared to the 70-75% typical of manual methods. This material optimization has reduced our leather costs by 22% while maintaining the same production output.

How does computer vision enhance cutting precision?

Computer vision systems integrated with AI can identify subtle material variations, color inconsistencies, and structural flaws that might compromise final product quality. In our silk scarf production, AI vision inspection detects weaving imperfections and directs the cutting system to avoid these areas while still maximizing usable material. This dual focus on quality preservation and waste reduction has decreased our premium fabric waste by 38% while improving overall product quality consistency.

How does AI improve material selection and substitution?

Material selection profoundly impacts cost, sustainability, and product performance, yet manufacturers often default to familiar materials without exploring potentially superior alternatives. The complexity of evaluating multiple material attributes—cost, durability, sustainability, availability, and production compatibility—makes optimal selection challenging.

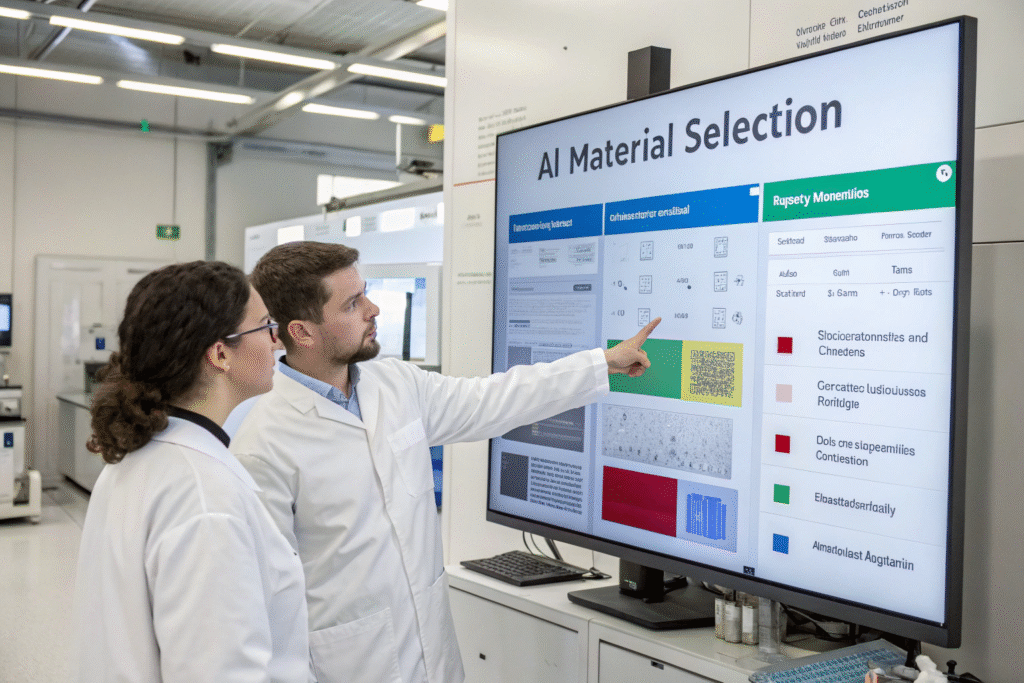

AI systems analyze vast material databases, performance requirements, and sustainability metrics to recommend optimal material choices that meet design specifications while reducing costs and environmental impact.

How can AI identify cost-effective material alternatives?

AI material recommendation engines compare hundreds of material options against specific accessory requirements, identifying alternatives that offer similar performance at lower cost or with better sustainability profiles. When material prices fluctuate, our system automatically suggests viable substitutes that maintain quality standards while reducing expenses. For our hair accessory line, AI identified a recycled polymer alternative that provided equivalent durability to virgin plastic at 18% lower cost, with the added benefit of appealing to eco-conscious consumers.

What role does predictive analysis play in material procurement?

AI demand forecasting combined with material analytics enables smarter purchasing decisions by predicting optimal order quantities and timing based on price trends, availability projections, and production schedules. Our system analyzes historical price data, commodity market trends, and supplier performance to recommend when to purchase materials like metal components for jewelry or synthetic fabrics for bags. This predictive procurement has reduced our material costs by 14% while eliminating stockouts of critical materials.

How does AI enhance sustainable material practices?

Sustainability has become increasingly important in fashion accessories, with consumers and regulators demanding more environmentally responsible practices. However, quantifying environmental impact and identifying genuinely sustainable options requires analyzing complex life cycle data beyond most manufacturers' capabilities.

AI systems process comprehensive environmental data to guide material decisions that reduce ecological impact while maintaining product quality and cost targets.

How does AI evaluate and compare material sustainability?

AI sustainability assessment tools analyze life cycle data including water usage, carbon footprint, chemical composition, and end-of-life disposal implications across material options. For our scarf collection, the AI system recommended switching to a digitally-printed organic cotton that reduced water consumption by 63% compared to our previous conventionally printed polyester, while maintaining the vibrant colors our customers expect. This sustainable optimization has become a significant marketing advantage while reducing our environmental compliance risks.

Can AI help develop new sustainable materials?

AI-driven material science accelerates development of innovative sustainable materials by predicting molecular structures and material properties before physical testing. We're collaborating with material science partners using AI to develop bio-based alternatives to traditional plastics for hair accessories and decorative elements. The AI models simulate how different biological compounds would perform, significantly reducing the trial-and-error typically required in material innovation. This approach has cut our new material development time by approximately 60%.

How does AI optimize inventory and waste management?

Material inventory represents tied-up capital, while waste represents lost value. Traditional inventory management often results in either excessive material stocks or production delays due to material shortages, with waste tracking typically limited to basic categorization.

AI transforms material inventory and waste management through precise forecasting, real-time tracking, and proactive optimization that minimizes both excess inventory and material waste.

How does AI improve material inventory precision?

AI inventory optimization analyzes production schedules, supplier lead times, and material usage patterns to maintain optimal stock levels. The system automatically adjusts reorder points and quantities based on changing production needs and market conditions. For our metal component inventory used in jewelry and belt buckles, AI optimization has reduced inventory carrying costs by 31% while eliminating production stoppages due to material shortages through more accurate demand forecasting.

How can AI transform waste into value?

AI waste analytics identify patterns in material waste generation, enabling targeted reduction strategies and identifying opportunities for waste repurposing. Our system detected that specific scarf cutting patterns generated geometrically shaped remnants that could be repurposed as decorative elements for hair accessories rather than being discarded. This waste valorization initiative has created a new product line while reducing our fabric waste by 27%, turning a cost center into a revenue stream.

Conclusion

AI is revolutionizing material optimization in fashion accessory manufacturing by bringing data-driven precision to processes traditionally governed by experience and estimation. Through cutting optimization, intelligent material selection, sustainable practice enhancement, and waste reduction, AI systems deliver substantial cost savings, environmental benefits, and operational improvements.

As AI technologies continue to advance and become more accessible, manufacturers who embrace these tools will gain significant competitive advantages through reduced material costs, improved sustainability credentials, and enhanced production efficiency—all while meeting evolving consumer expectations for responsibly produced accessories.

If you're interested in implementing AI-driven material optimization for your accessory production or want to partner with a manufacturer that leverages advanced AI systems, we invite you to contact our Business Director, Elaine. She can discuss our AI capabilities and how they can reduce your material costs while improving sustainability. Reach her at: elaine@fumaoclothing.com.