Real-time cape supply represents a significant challenge in fashion manufacturing, where traditional production cycles of 60-90 days cannot meet rapidly changing demand patterns. Through our development of responsive manufacturing systems specifically for cape production, we've created strategies that dramatically reduce lead times while maintaining quality and cost efficiency.

Supplying capes in real time requires implementing demand sensing technologies, flexible manufacturing systems, strategic inventory positioning, digital supply chain integration, and responsive logistics solutions that collectively transform traditional sequential processes into synchronized, responsive operations.This approach enables manufacturers to respond to actual demand signals rather than relying solely on forecasting.

Real-time supply transforms the fundamental business model from push-based to pull-based manufacturing. Let's examine the specific systems and strategies that enable responsive cape supply.

How can demand sensing enable real-time response?

Traditional supply chains rely on historical forecasting that often misses emerging trends and demand shifts. Real-time supply begins with accurate, immediate demand capture that triggers production responses.

Advanced demand sensing transforms how manufacturers detect and respond to market needs, creating supply chains that react to actual sales rather than predictions.

What point-of-sale integration provides immediate demand signals?

Delayed sales data prevents real-time response. We've implemented direct POS integration that streams sales data from retail partners into our production planning systems within minutes of transactions. The system analyzes sell-through rates, size distributions, and geographic patterns to identify emerging demand signals. For cape collections, this means we detect which styles, colors, and sizes are moving fastest and can adjust production accordingly. The most advanced implementation includes algorithmic demand interpretation that distinguishes between temporary fluctuations and sustained trends, preventing overreaction to noise while capturing genuine shifts. This immediate demand visibility has reduced our response time from weeks to hours.

How does social listening predict demand before it materializes?

Sales data reveals what's already happening, but social intelligence predicts what will happen. Our AI-powered social listening systems analyze fashion conversations, influencer content, and visual social media to detect emerging cape trends before they impact sales. The systems track mention volume, sentiment trends, and style references across platforms including Instagram, TikTok, and Pinterest. When a particular cape style begins gaining traction online, we can initiate small production runs before retailers even place orders. This predictive approach has enabled us to supply trending capes exactly when demand peaks, rather than arriving after the trend has passed.

What flexible manufacturing systems enable rapid production?

Traditional cape manufacturing involves lengthy processes that cannot accelerate sufficiently for real-time supply. Flexible manufacturing redesigns production for speed, adaptability, and small-batch efficiency.

Manufacturing transformation creates systems that can rapidly shift between styles, colors, and quantities without significant downtime or cost penalties.

How does modular production design accelerate manufacturing?

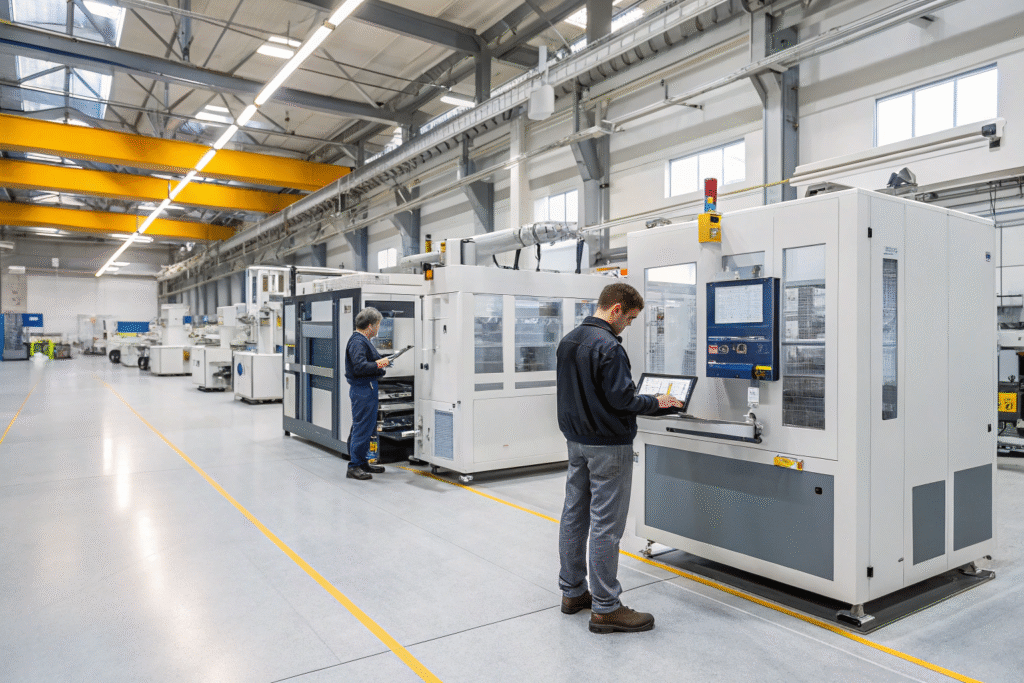

Traditional production lines optimized for volume struggle with rapid style changes. We've implemented modular manufacturing cells dedicated to cape production that can be rapidly reconfigured for different styles. Each cell contains universal equipment that handles various fabrics and designs without retooling. For cape-specific challenges like hood attachments, clasp installations, and lining operations, we've developed quick-change fixtures that adjust in minutes rather than hours. The cells operate on kanban replenishment systems that maintain material flow without excessive inventory. This modular approach has reduced our changeover time from days to hours while maintaining quality standards across different cape designs.

What digital manufacturing technologies reduce processing time?

Traditional pattern making, cutting, and sewing create significant time lags. We've integrated digital end-to-end systems that accelerate each production stage. Automated nesting software optimizes fabric layout within minutes rather than the hours required for manual marking. Computer-controlled cutting executes perfect patterns in a fraction of traditional cutting time. Digitally-guided sewing stations provide operators with visual instructions that reduce decision time and errors. The most significant time savings comes from 3D design and virtual prototyping that eliminates physical samples for production approval. These digital technologies have compressed our cape production timeline from weeks to days while improving accuracy and reducing waste.

How does strategic inventory positioning support real-time supply?

Maintaining excessive finished goods inventory contradicts real-time principles, but strategic raw material and component inventory enables rapid response without the costs and risks of finished product stockpiling.

Intelligent inventory management balances availability requirements with capital efficiency through careful positioning of different inventory types.

What raw material strategies enable rapid production?

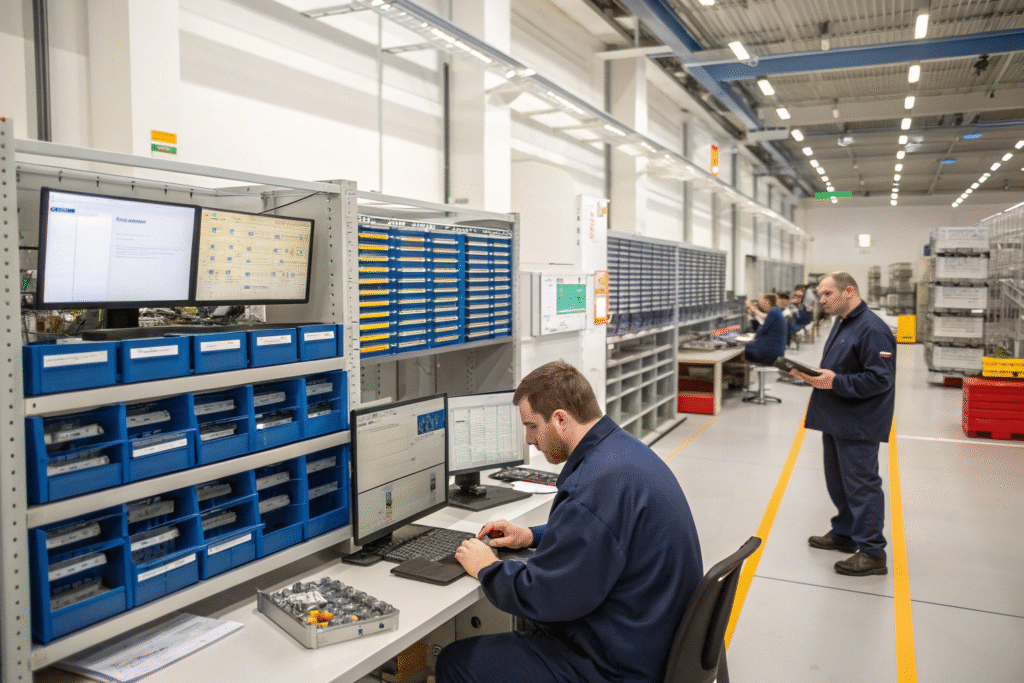

Cape production requires various fabrics, linings, closures, and decorative elements that traditionally have long lead times. We maintain strategic fabric inventory of proven performers that can be quickly converted into multiple cape styles. Our fabric library system includes materials with demonstrated market appeal and manufacturing efficiency. For closures and hardware, we've established vendor-managed inventory arrangements where suppliers maintain consignment stock at our facilities. The most innovative approach involves collaborative inventory planning with fabric mills where we share demand data to ensure priority access to materials during peak demand periods. This raw material strategy has enabled us to launch production within 24 hours of demand signals.

How do semi-finished components accelerate final assembly?

Complete cape manufacturing from raw materials requires significant time, but strategic use of semi-finished components compresses the timeline. We maintain standardized cape bases in neutral colors that can be quickly customized with trim, embroidery, or surface treatments. For lined capes, we pre-assemble lining modules that attach rapidly to outer shells. Hood and collar components are prepared in advance for quick integration. This modular approach allows us to maintain minimal finished goods inventory while achieving near-immediate response capabilities for customized or trending items. The system has been particularly effective for seasonal cape collections where base styles remain constant while decorative elements follow fashion trends.

How does digital supply chain integration enable synchronization?

Traditional supply chains operate with limited visibility between partners, creating delays and misalignments. Digital integration creates seamless information flow that synchronizes all supply chain participants.

Connected digital systems transform separate organizations into coordinated networks that respond collectively to demand signals.

What cloud platforms enable partner collaboration?

Isolated information systems create communication delays between manufacturers, suppliers, and distributors. We've implemented cloud-based collaboration platforms that provide all supply chain partners with real-time visibility into demand, inventory, and production status. The systems include automated alert protocols that notify partners immediately when action is required. For cape production, this means fabric suppliers see our material needs as they emerge, trim manufacturers adjust their production schedules accordingly, and logistics providers prepare for upcoming shipments. This synchronization has reduced our overall supply chain response time by 60% while improving alignment between different partners' activities.

How does blockchain technology enhance transparency and trust?

Supply chain partners often hesitate to share sensitive information without assurance of how it will be used. Our blockchain-based supply chain system creates trusted transparency where all participants see relevant information without compromising confidentiality. Each cape's journey from raw material to finished product is recorded in an immutable distributed ledger that verifies authenticity, quality certifications, and ethical compliance. This transparency has been particularly valuable for luxury cape collections where provenance and authenticity contribute significantly to value proposition. The trust enabled by blockchain technology has encouraged deeper supply chain collaboration and faster collective response to market opportunities.

How do responsive logistics solutions complete real-time supply?

Manufacturing speed provides limited value if logistics systems cannot deliver products rapidly to where they're needed. Responsive logistics completes the real-time supply chain by ensuring physical products move as quickly as information.

Modern logistics solutions transform traditional transportation from scheduled movements to dynamic routing based on immediate needs.

What distributed fulfillment enables rapid delivery?

Centralized warehouse systems create significant delays in getting products to end customers. We've implemented distributed fulfillment networks that position inventory closer to demand points. The system uses demand forecasting algorithms to pre-position base cape styles in regional fulfillment centers while maintaining customization capabilities at central facilities. For emergency replenishment, we've established express logistics partnerships that guarantee 24-48 hour delivery to most major markets. The most innovative approach involves store-as-warehouse utilization where retail inventory serves double duty for both walk-in customers and e-commerce fulfillment. This distributed approach has reduced our average delivery time from weeks to days.

How does dynamic routing optimize transportation?

Traditional logistics operates on fixed schedules regardless of urgency. Our dynamic routing systems continuously evaluate shipment priorities and transportation options to minimize delivery time. The systems integrate real-time transportation visibility that tracks shipments and identifies potential delays before they occur. When urgent cape orders require expedited shipping, the system automatically identifies the optimal routing and carrier combination. For international shipments, we utilize consolidation services that maintain speed while controlling costs. This dynamic approach has enabled us to provide retailers with near-immediate replenishment while avoiding the cost penalties typically associated with expedited shipping.

Conclusion

Supplying capes in real time requires transforming traditional sequential supply chains into responsive, integrated systems that synchronize demand sensing, flexible manufacturing, strategic inventory, digital collaboration, and responsive logistics. Companies achieving real-time supply capabilities gain significant competitive advantages through reduced markdowns, improved customer satisfaction, and better capital utilization. The investment in responsive systems pays dividends through increased sales, stronger retailer relationships, and enhanced brand reputation for availability and relevance.

If you're looking to develop real-time supply capabilities for your cape collections, we invite you to contact our Business Director, Elaine. Our experience in building responsive supply chains for fashion accessories can help you achieve similar transformation. Reach her at: elaine@fumaoclothing.com.