Securing a contract to supply hair clips to a major supermarket chain is a significant opportunity that comes with a unique set of demands. It’s not just about selling a trendy product; it’s about becoming a reliable, long-term partner in a massive, fast-moving supply chain. The requirements go far beyond everyday wholesale, demanding exceptional consistency, compliance, and scale.

Succeeding with major retailers means mastering four critical pillars: aligning with commercial buyer demands for compliance and scale, selecting suppliers with proven retail experience, navigating stringent quality and certification requirements, and building a partnership that ensures long-term reliability. Miss any one of these, and the partnership is at risk.

This guide breaks down these essential components to help you structure your sourcing strategy for maximum success and credibility with large retail buyers.

What are the commercial demands of major supermarket buyers?

Before you even approach a supplier, you must understand the non-negotiable commercial terms demanded by large retailers. Their primary focus is on minimizing risk and ensuring seamless integration into their national or global operations.

These buyers prioritize suppliers who offer full compliance documentation, competitive landed costs, and unwavering logistical reliability. For hair clips, this includes providing safety test reports (like CPSIA for the US market), ensuring all materials meet international standards, and having a flawless track record for on-time, in-full (OTIF) delivery. A single failed shipment or compliance issue can result in hefty chargebacks and loss of business.

To dive deeper, you need to structure your sourcing to meet two specific, high-stakes commercial requirements.

How to structure pricing for large-volume, low-margin orders?

Supermarkets operate on thin margins and expect their suppliers to do the same. Your pricing must account for the total landed cost, not just the factory unit price. This includes freight, insurance, duties, and any in-country handling. To remain competitive, you must work with manufacturers capable of true scale, where economies of magnitude significantly lower the per-unit cost. Negotiate based on annual volume commitments rather than per-order quotes. Furthermore, understanding and optimizing the Harmonized System (HS) code for your hair clips is crucial, as it directly impacts the duty rate applied at customs, a key component of your final cost. Learn more Shanghai Fumao Clothing details page.

What logistics capabilities are non-negotiable for national distribution?

Your supplier must have experience with the complex logistics of big-box retail. This includes consolidated container shipping to reduce costs, the ability to ship directly to a retailer’s distribution centers (DC), and compliance with their specific routing guides and Advanced Shipment Notice (ASN) requirements. Inquire if the factory has dedicated logistics teams and established relationships with freight forwarders. For example, some experienced manufacturers utilize solutions like Less than Container Load (LCL) for smaller orders and have systems to ensure stable sailing schedules, which is critical for avoiding costly delays in the retail calendar.

How to identify and vet a supplier with retail chain experience?

Not all factories are created equal. The most critical filter in your search is finding a partner with a verifiable track record of supplying other major retailers or brands. This experience is your best guarantee that they understand the high-stakes environment.

Look for suppliers who explicitly list major retailers or global brands as clients. For instance, some manufacturers publicly note that they serve clients like Walmart, Target, Dollar General, and Disney. This is a strong indicator that they have already passed rigorous vetting processes. During evaluation, request and actually contact references from their retail clients to verify their claims on reliability, communication, and problem-solving.

Vetting such a supplier requires a two-pronged approach: scrutinizing their operational scale and evaluating their design and development support.

What factory audit points prove capability for large-scale orders?

You must verify the supplier's capacity beyond their marketing claims. Key audit points include:

- Production Volume & MOQ Flexibility: Can they handle an order for 500,000 units and also accommodate smaller, trend-driven test orders? Ask about their monthly output capacity.

- In-house Quality Control: Do they have a dedicated, independent QC team and internal testing labs? A factory with its own chemical testing lab for heavy metals, for instance, shows advanced capability.

- Automation Level: Automated production lines (e.g., high-speed weaving machines, automatic packaging) ensure consistency and speed for high-volume orders.

Why is ODM/OEM capability crucial for a supermarket's private label?

Major chains often want private-label (own-brand) products. Your supplier must offer strong OEM/ODM services. This means they can produce hair clips to the retailer's exact specifications, using custom molds, colors, and packaging with the retailer's logo. Assess their design team's ability to translate trends into producible samples. A supplier that can act as an extension of your—and the retailer's—product development team is invaluable.

What quality and certification standards must be met?

For supermarkets, quality is a safety and liability issue. Their standards are codified in detailed technical manuals that you must obtain and adhere to. Failure to meet these can result in rejected shipments, financial penalties, and permanent removal from their supplier list.

The baseline expectation is a robust, multi-stage quality management system. This includes Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Pre-shipment Inspection. The final inspection should follow the Acceptable Quality Limit (AQL) sampling method, typically at Level II for general merchandise, which defines the maximum number of allowable defects.

Beyond general systems, you must ensure compliance with two specific, high-risk areas.

Which product safety certifications are mandatory?

Certifications are non-negotiable and vary by market. For the United States, CPSIA compliance (for children's products) and general safety standards from labs like Intertek or UL are often required. For the European Union, CE marking and REACH compliance (for chemicals) are essential. Your supplier should be proactive in understanding these and able to provide valid, recent test reports from accredited third-party labs for the exact materials and products you are sourcing.

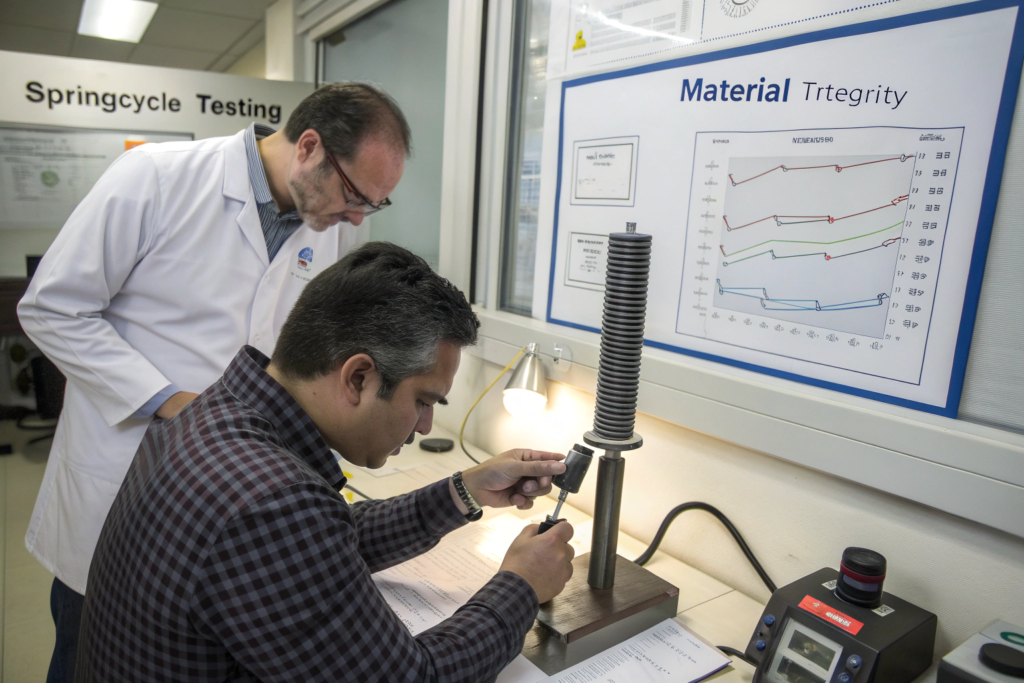

How to ensure durability that prevents customer returns?

Hair clips are high-frequency use items. The #1 point of failure is the hinge and spring mechanism. Your supplier must demonstrate a focus on durability. Require them to provide data on spring cycle testing (e.g., the clip can be opened and closed thousands of times without losing tension). Also, verify the quality of materials: metal parts must be rust-proof, and plastic/acetate components must be shatter-resistant. Acetate is a premium, plant-based material noted for its durability and rich colors, making it a excellent choice for higher-tier products.

How to build a partnership, not just a transaction?

Supplying a supermarket is a marathon, not a sprint. They seek partners who will grow with them, solve problems proactively, and contribute to their long-term success. A transactional relationship focused only on price will not survive the first major challenge.

A true partnership is characterized by transparent communication, joint business planning, and continuous improvement. This means having a dedicated, experienced project manager on the supplier side who provides weekly updates, anticipates issues (like material price fluctuations), and suggests value-engineering improvements without compromising quality.

Cultivating this level of partnership requires investment in two key relational areas.

What does effective, proactive communication look like?

It goes beyond responding to emails. It involves the supplier sharing regular production status reports, early warnings of potential delays, and insights on raw material markets. They should use collaborative platforms (like Asana, Trello, or a secure portal) to share documents and track progress. The ability to communicate effectively in the buyer's language and across time zones is fundamental to building trust and avoiding costly misunderstandings.

Why is a joint innovation and trend response strategy valuable?

Supermarkets need to stay relevant. A partner factory that monitors global hair accessory trends (like oversized claws, geometric designs, and sustainable materials) and can quickly translate them into commercial samples provides immense value. Discuss their design team's size and process. Can they help you develop exclusive products that give the retailer a competitive edge? This strategic collaboration moves you from a vendor to an indispensable part of their product success.

Conclusion

Sourcing hair clips for major supermarket chains is a complex but achievable goal that requires a strategic, detail-oriented approach. It demands a deep understanding of the retailer's commercial and logistical frameworks, partnering exclusively with suppliers whose scale and experience are proven, mastering a rigorous world of quality and safety certifications, and, above all, fostering a communicative, proactive partnership.

By methodically addressing each of these pillars, you build a supply chain that is not just a source of products, but a foundation for reliable, profitable, and long-term growth. If you are looking for a manufacturing partner with the experience, quality systems, and commitment to help you succeed in the major retail space, let's discuss your specific needs. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore how we can support your next big opportunity.