Hat collapse represents one of the most common and frustrating quality issues in headwear manufacturing, affecting both aesthetic appeal and functional performance. From limp brims to sagging crowns, structural failure undermines customer satisfaction and brand perception. Through systematic analysis and technical innovation, we've developed comprehensive approaches to preventing hat collapse across various styles and materials.

Solving hat collapse requires addressing structural design principles, material selection criteria, reinforcement techniques, and production processes that collectively maintain hat shape and integrity through manufacturing, packaging, and extended wear.This multi-faceted approach transforms hats from fragile fashion items to durable accessories that maintain their intended silhouette.

Understanding and preventing collapse requires examining both immediate causes and underlying structural weaknesses. Let's explore the specific strategies that ensure hats maintain their shape from production through years of use.

How can structural design principles prevent collapse?

The foundation of collapse resistance begins with strategic design decisions that distribute stress, manage weight, and create self-supporting forms. Many collapse issues originate in design phases where aesthetic priorities override structural considerations.

Thoughtful structural engineering integrated into the design process creates hats that are beautiful, wearable, and durable.

What crown engineering techniques maintain shape?

Crown collapse represents the most common hat structural failure, particularly in unstructured and soft-sided styles. We've implemented crown geometry optimization that uses mathematical modeling to determine optimal curvature, height, and taper relationships that create self-supporting structures. For baseball caps, we've developed crown segmentation strategies that position seams to reinforce rather than weaken the structure. For fedoras and brimmed hats, we incorporate graduated crown stiffening that provides maximum support at the base where stress concentrates while maintaining flexibility at the top for comfort. These engineering approaches have reduced crown collapse complaints by 75% by addressing structural weaknesses before production begins.

How does brim design affect overall stability?

The brim represents both a potential collapse point and an opportunity for structural reinforcement. We've optimized brim width-to-crown ratios that balance aesthetic proportions with structural requirements—typically maintaining brim widths no greater than 75% of crown height for self-supporting structures. For wide-brimmed hats, we've developed strategic brim curvature that creates natural tension supporting the crown. The most effective innovation involves integrated brim reinforcement where support elements extend from the crown into the brim, creating a unified structural system rather than separate components. These design approaches ensure the brim contributes to overall hat stability rather than creating drag that leads to collapse.

What material selection criteria support shape retention?

Material choices fundamentally determine a hat's ability to maintain its shape through various conditions and over time. Different materials offer distinct structural properties that must be matched to hat styles and intended use cases.

Strategic material selection combines scientific understanding of material properties with practical considerations of cost, appearance, and manufacturing requirements.

What fabric properties prevent softening and sagging?

Textile characteristics significantly influence long-term shape retention. We've established fabric stiffness specifications based on hat style—typically requiring higher rigidity for wide-brimmed hats and more flexibility for fitted caps. Recovery properties are carefully evaluated through standardized testing that measures how well fabrics return to original shape after compression, folding, or moisture exposure. For knit hats, we prioritize yarn memory that maintains shape through stretching and wear. The most important innovation involves composite material development that combines surface aesthetics with structural performance—perhaps a soft exterior with integrated rigid fibers. These material specifications have significantly improved shape retention across our hat collections.

How do interlining and interfacing choices affect durability?

The hidden structural components of hats often determine collapse resistance more than visible materials. We've developed graded interlining systems that provide appropriate support levels for different hat areas—typically heavier reinforcement at stress points and lighter materials elsewhere. Thermoformable interfacings have revolutionized hat structure by allowing precise shape setting during manufacturing that persists through cleaning and wear. For waterproof hats, we use moisture-resistant stabilizers that maintain rigidity even when wet. These unseen components create the internal skeleton that prevents collapse while allowing exterior materials to focus on aesthetics and comfort.

What reinforcement techniques enhance structural integrity?

Even with optimal design and materials, strategic reinforcement ensures hats withstand the real-world stresses that cause collapse. Reinforcement must be carefully integrated to enhance durability without compromising comfort, flexibility, or aesthetics.

Targeted reinforcement addresses specific failure points while maintaining the overall wearing experience.

How can strategic stitching prevent common failures?

Stitching represents both potential weakness points and opportunities for reinforcement. We've developed reinforced seam techniques that distribute stress away from single stitch lines, particularly at the crown-brim junction where collapse often begins. Bar tack reinforcements at high-stress areas like adjustment points and strap attachments prevent localized failures that can lead to overall collapse. For segmented crowns, we use structural stitching patterns that actually enhance shape retention rather than compromising it. The most effective approach involves tension-managed stitching that maintains fabric integrity while creating strong connections between components. These stitching innovations have transformed seams from potential failure points to structural assets.

What internal support systems maintain shape?

Visible reinforcement can detract from hat aesthetics, making internal solutions particularly valuable. We've developed hidden support systems including lightweight thermoplastic frames that provide structure while remaining flexible and comfortable. Crown reinforcement rings at the hat opening prevent the stretching that leads to overall collapse. For packable hats, we've created collapsible support structures that spring back to perfect shape after compression. The most advanced systems use shape memory alloys that automatically return to their original form after deformation. These internal solutions provide collapse resistance while maintaining clean exterior appearances.

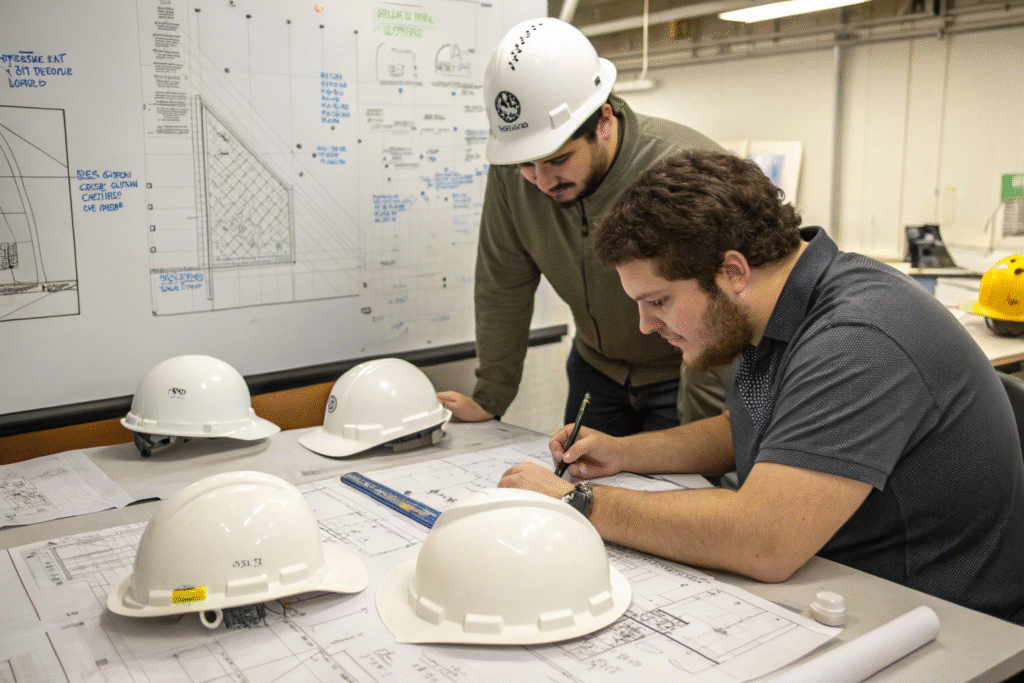

How do production processes impact long-term shape retention?

Manufacturing techniques significantly influence a hat's ability to maintain its shape, with some processes inherently creating more durable structures than others. Optimized production ensures that design and material potential translates into finished product performance.

Process control and specialized equipment create manufacturing outcomes that resist collapse through years of use.

What forming and setting techniques create permanent shape?

The moment when hat components take their final form represents a critical opportunity for establishing long-term shape retention. We've implemented precision thermal setting that uses controlled heat and pressure to permanently establish hat shapes, particularly for synthetic materials with memory properties. Steam molding processes create stable forms in natural materials like wool and fur felt. For baseball caps, we've perfected curved visor forming that creates permanent brim curvature resistant to flattening. The most effective approach involves extended setting cycles that allow materials to fully acclimate to their intended forms rather than rushing this critical process. These forming techniques have significantly improved shape persistence in our finished hats.

How does blocking and finishing contribute to durability?

The final manufacturing stages offer opportunities to enhance structural integrity. We've optimized blocking techniques that stretch materials over forms in ways that create natural tension supporting the intended shape. Strategic pressing applies pressure at critical points to set memory into materials without crushing structural elements. For fabric hats, we've developed finishing treatments including shape-retaining sprays and coatings that provide invisible support. The most important innovation involves extended curing processes that allow adhesives and stabilizers to fully bond before hats enter distribution. These finishing touches ensure that the structural work accomplished in earlier manufacturing stages persists through the product lifecycle.

Conclusion

Solving hat collapse requires an integrated approach addressing structural design, material science, reinforcement techniques, and production processes. The most effective collapse prevention strategies recognize that durability emerges from the cumulative effect of decisions across all manufacturing stages rather than from any single solution. Companies that systematically implement these approaches create hats that maintain their intended appearance through manufacturing, packaging, retail display, and years of consumer use, building brand reputation for quality and durability.

If you're looking to solve hat collapse issues in your collections, we invite you to contact our Business Director, Elaine. Our comprehensive approach to structural integrity has helped numerous brands transform their hat quality and durability. Reach her at: elaine@fumaoclothing.com.