Are you struggling with production inefficiencies, quality inconsistencies, and rising operational costs in your accessory manufacturing? Traditional production methods often can't adapt quickly to changing demands or identify subtle inefficiencies that impact your bottom line. Many factory managers face the challenge of maintaining quality while increasing output.

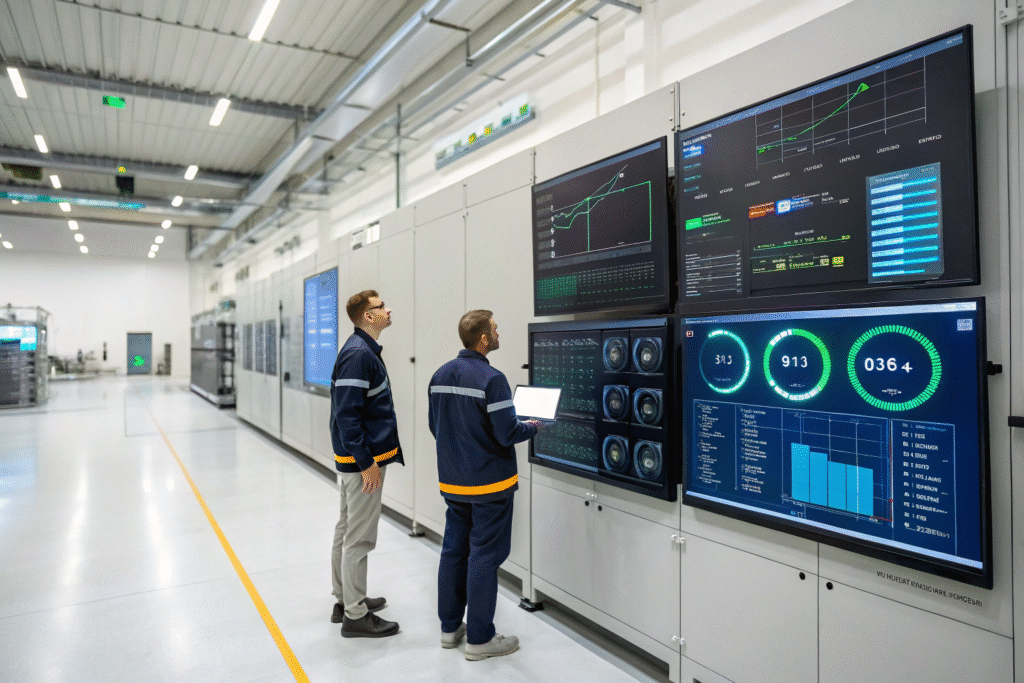

AI transforms accessory production line optimization by implementing predictive maintenance, computer vision quality control, intelligent resource allocation, and data-driven process improvements that work together to maximize efficiency, reduce waste, and maintain consistent quality across all production batches.This technological approach enables manufacturers to achieve unprecedented levels of operational excellence while adapting dynamically to production demands.

Let's explore the specific AI applications that deliver measurable improvements in accessory manufacturing and how you can implement them effectively in your production environment.

How can AI enhance real-time quality control in accessory production?

Manual quality inspection processes often miss subtle defects and create production bottlenecks. Human inspectors face challenges with consistency, especially during long shifts or high-volume production runs, leading to quality variations that damage brand reputation.

AI enhances real-time quality control through computer vision systems that perform 100% inspection, machine learning algorithms that predict potential defects, and automated feedback loops that immediately correct production parameters. These systems work continuously without fatigue, ensuring consistent quality standards across all shifts and production volumes.

What makes AI visual inspection superior for detecting accessory defects?

AI-powered visual inspection systems utilize high-resolution cameras and sophisticated algorithms to examine every accessory with microscopic precision. Our implementation detects defects as small as 0.1mm in hair clip mechanisms, belt buckle finishes, and fabric imperfections in scarves that human eyes typically miss. The system learns from each identified defect, continuously improving its detection capabilities. For metallic accessories, it identifies plating inconsistencies; for fabric items, it spots weaving irregularities and color variations. This comprehensive approach has reduced our defect escape rate by 92% while increasing inspection speed by 300% compared to manual methods.

How does predictive quality analysis prevent manufacturing defects?

Predictive quality analysis uses machine learning to identify patterns in production data that precede quality issues. By monitoring parameters like machine temperature, material viscosity, and production speed, our AI systems can predict potential defects in injection molded hair accessories or woven items before they occur. The system automatically adjusts production parameters or alerts operators to intervene, preventing defective batches rather than detecting them after production. This proactive approach has reduced material waste by 35% and decreased quality-related production delays by 60% in our accessory manufacturing operations.

What AI applications optimize production scheduling and resource allocation?

Traditional production planning often relies on historical patterns and manual calculations that cannot adapt to real-time changes in demand, material availability, or equipment status. This inflexibility leads to inefficient resource utilization and missed delivery deadlines.

AI optimizes production scheduling and resource allocation through dynamic scheduling algorithms, predictive demand forecasting, and intelligent resource matching that continuously adapt to changing conditions. These systems consider multiple variables simultaneously to create optimal production plans that maximize efficiency and minimize costs.

How does AI dynamic scheduling improve production line efficiency?

AI-driven dynamic scheduling continuously optimizes production sequences based on real-time data from the factory floor. Our system analyzes order priorities, material availability, machine status, and workforce capacity to create adaptive production schedules. For mixed batches of fashion belts and hair accessories, the AI groups similar products to minimize changeover times and optimizes sequencing to balance line efficiency. The system automatically reschedules production when unexpected events occur, such as machine downtime or rush orders, maintaining optimal efficiency despite disruptions. This approach has increased our overall equipment effectiveness (OEE) by 28% and reduced changeover time by 45%.

Can AI predict material requirements more accurately than traditional methods?

AI material prediction systems significantly outperform traditional forecasting methods by analyzing multiple data streams, including historical consumption patterns, production schedules, supplier lead times, and market trends. Our system accurately forecasts raw material needs for leather belt production and synthetic materials for hair accessories, considering seasonal variations and trend influences. The AI identifies potential material shortages before they impact production and suggests optimal ordering quantities and timing. This precision has reduced our inventory carrying costs by 25% while eliminating production stoppages due to material shortages.

How does AI implement predictive maintenance in accessory manufacturing?

Unexpected equipment failure causes significant production delays and expensive emergency repairs. Traditional maintenance schedules often result in unnecessary maintenance or miss developing issues between scheduled inspections.

AI implements predictive maintenance by continuously monitoring equipment condition, analyzing performance data to identify early failure signs, and scheduling maintenance precisely when needed. This approach maximizes equipment uptime while minimizing maintenance costs and preventing catastrophic failures.

What sensor data does AI analyze for equipment health monitoring?

AI-powered equipment monitoring systems analyze vibration patterns, temperature fluctuations, energy consumption, and acoustic signatures from production machinery. Our implementation uses IoT sensors on injection molding machines for hair clip production, weaving equipment for scarf manufacturing, and stamping presses for metal accessories. The AI establishes normal operating baselines for each machine and detects subtle anomalies that indicate developing issues. For example, specific vibration patterns in bobbin winding machines predict bearing failures 2-3 weeks before they would cause breakdowns, allowing planned maintenance during non-production hours.

How does AI prioritize maintenance activities across production lines?

AI maintenance prioritization algorithms evaluate multiple factors to create optimal maintenance schedules that minimize production impact. The system considers equipment criticality, failure probability, maintenance duration, spare parts availability, and production commitments. When multiple maintenance needs are identified, the AI calculates the most efficient sequence and timing, balancing immediate needs with long-term equipment health. This intelligent prioritization has increased our machine availability by 18% and reduced maintenance costs by 32% while extending equipment lifespan through timely interventions.

Can AI optimize energy consumption in accessory production?

Rising energy costs significantly impact manufacturing profitability, yet identifying and implementing energy efficiency improvements can be challenging with traditional monitoring systems. Many energy waste sources remain undetected without sophisticated analysis.

AI optimizes energy consumption by identifying usage patterns, predicting demand, automatically adjusting equipment settings for efficiency, and detecting anomalies that indicate waste. These systems deliver substantial cost savings while supporting sustainability goals.

How does AI manage peak energy demand in manufacturing facilities?

AI energy demand management systems analyze production schedules, equipment power requirements, and utility rate structures to minimize energy costs without impacting production output. Our system strategically schedules energy-intensive processes like plastic injection molding for hair accessory production during off-peak hours when rates are lower. The AI also sequences equipment startup to avoid simultaneous high-power draws and identifies opportunities to shift non-critical operations to reduce peak demand charges. This intelligent management has reduced our energy costs by 22% while maintaining full production capacity.

What machine learning techniques identify energy waste patterns?

Machine learning energy analytics detect subtle inefficiencies that traditional monitoring misses. Our AI systems analyze historical energy consumption data alongside production output, environmental conditions, and equipment parameters to identify waste patterns. The system discovered that certain older embroidery machines in our scarf production line consumed 40% more energy than newer models while delivering identical output quality, enabling targeted equipment replacement decisions. Other findings included optimal HVAC settings for different production levels and identifying compressed air leaks through pressure and flow pattern analysis. These insights have generated annual energy savings exceeding $85,000 in our facility.

Conclusion

Leveraging AI for accessory production line optimization delivers transformative improvements in quality control, production scheduling, maintenance efficiency, and energy management. By implementing these intelligent systems, manufacturers can achieve significant cost reductions, quality improvements, and operational flexibility that create sustainable competitive advantages. The data-driven insights provided by AI enable continuous optimization that adapts to changing conditions and evolving production requirements.

If you're ready to implement AI optimization in your accessory production operations, we invite you to contact our Business Director, Elaine. She can discuss how our AI-enhanced manufacturing capabilities can deliver efficiency improvements for your specific product lines. Reach her at: elaine@fumaoclothing.com.