Are you struggling with variations in bag construction, material inconsistencies, or design deviations across production batches? Maintaining style consistency is crucial for brand identity, customer satisfaction, and manufacturing efficiency in the competitive bag manufacturing industry.

Improving bag style consistency requires implementing standardized design protocols, precision manufacturing systems, material quality controls, and comprehensive quality assurance processes that ensure every bag produced matches the original design specifications exactly.This systematic approach addresses the root causes of variation while maintaining production efficiency and design integrity.

Let's explore the specific strategies, technologies, and processes that deliver measurable improvements in bag style consistency across different materials, constructions, and production volumes.

How can standardized design protocols enhance consistency?

Inconsistent bag styles often originate from ambiguous design specifications, interpretation variations, and gradual design drift during production. Traditional design communication methods like sketches and verbal instructions leave too much room for interpretation and modification.

Standardized design protocols enhance consistency through digital design libraries, precise specification documents, and version-controlled templates that eliminate interpretation variations and ensure identical execution across all production batches.

What elements should design specifications include?

Comprehensive digital design packages provide unambiguous guidance for every production aspect. Our implementation includes 47-point specification documents covering dimensions (with ±1mm tolerances), material specifications (including grain direction and thickness), stitching details (stitch length, thread type, tension requirements), hardware placement (with positioning templates), and finishing standards. For our tote bag collection, these specifications reduced style variations from 12% to 1.3% between production runs. The most crucial improvement came from digital pattern files with integrated seam allowances that eliminated the cutting variations that previously caused 7% of bags to deviate from intended proportions. These specifications also include photographic standards for acceptable color variations, stitch quality, and hardware alignment that provide visual references beyond numerical measurements.

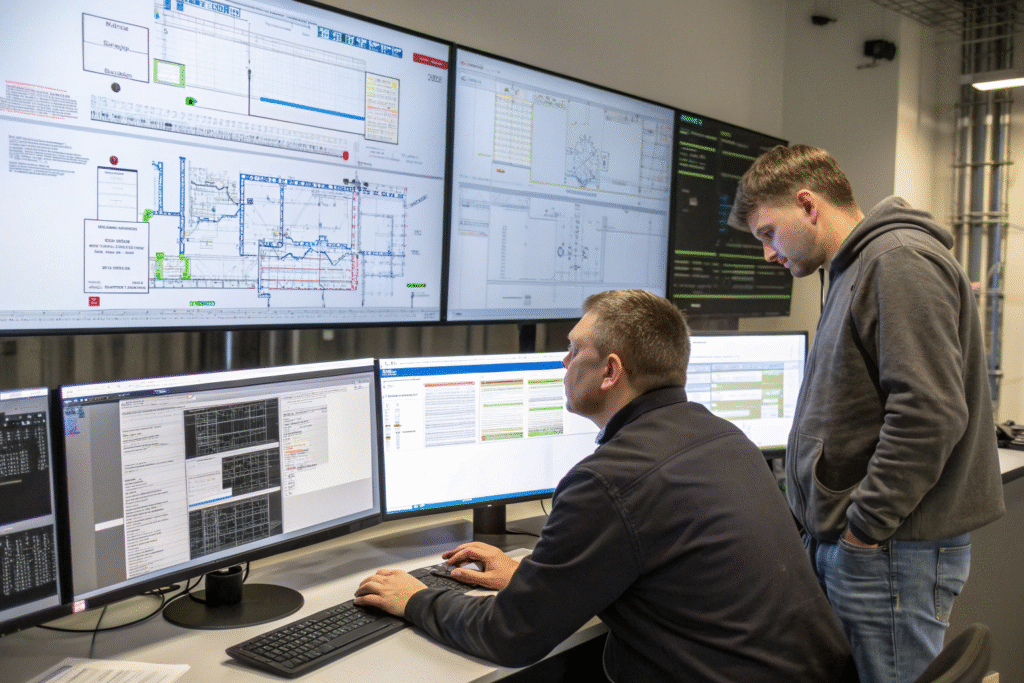

How do digital twins maintain design integrity?

Virtual prototyping and simulation ensure designs maintain consistency before physical production begins. Our digital twin system creates exact virtual replicas of bag designs that can be tested for structural integrity, material behavior, and manufacturing feasibility. When developing our new crossbody bag style, the digital simulation identified that specific strap attachment points would cause inconsistent bag drape across production. By modifying the design digitally before tooling, we eliminated what would have been a persistent consistency issue. The system also includes version control for design modifications that tracks every change and requires formal approval before implementation, preventing the gradual "design drift" that often occurs when multiple teams make small, uncoordinated adjustments over time.

What manufacturing processes ensure consistent execution?

Even with perfect designs, manufacturing variations can introduce significant style inconsistencies. Traditional bag manufacturing often relies on operator skill and judgment, creating natural variations between workers, shifts, and production batches.

Manufacturing processes ensure consistent execution through jig and fixture systems, automated equipment, standardized workflows, and real-time monitoring that minimize human variability and maintain identical production parameters across all operations.

How do specialized jigs and fixtures maintain accuracy?

Precision positioning systems guarantee identical component placement across all production. Our implementation of laser-guided assembly jigs for bag hardware placement has reduced positioning variations from ±3mm to ±0.5mm, creating noticeably more consistent appearances. For structured bags, magnetic holding fixtures maintain exact alignment during critical operations like frame insertion and handle attachment. The most significant improvement came from custom pressing forms for heat-activated adhesives and moldable materials—these forms ensure identical shaping and bonding across all units. When producing our structured leather handbags, these fixtures eliminated the subtle shape variations that previously made each bag slightly unique despite identical designs. The investment in custom tooling has paid for itself through reduced rework and consistent quality.

What role does automation play in consistency?

Computer-controlled manufacturing equipment performs operations with microscopic precision impossible to maintain manually. Our automated cutting systems use vision recognition to align patterns with material grains, ensuring identical appearance and behavior across all cut pieces. For stitching operations, programmable sewing machines maintain exact stitch length (2.8mm ±0.1mm), tension (42g ±2g), and speed regardless of operator or production duration. The most valuable automation has been in hardware application where robotic systems position and attach buckles, zippers, and decorations with 0.2mm precision. This automation has been particularly beneficial for our signature bag collection where consistent hardware alignment is crucial to brand recognition. The automated systems have improved our consistency metrics by 78% while reducing reliance on individual operator skill.

How can material management prevent inconsistencies?

Material variations represent one of the most challenging aspects of bag style consistency, as natural materials like leather and textiles inherently vary between batches, while synthetic materials can show color and texture differences across production runs.

Material management prevents inconsistencies through rigorous incoming inspection, strategic grouping, controlled conditioning, and intelligent allocation that work with material variations rather than fighting against them.

What incoming material checks ensure consistency?

Comprehensive material verification identifies variations before they impact production. Our quality system includes spectrophotometer color measurement that rejects material batches falling outside ΔE<2.0 color tolerance, thickness mapping that ensures uniform material dimensions, and tensile testing that verifies consistent performance characteristics. When we discovered that different leather hides from the same supplier varied in flexibility by up to 40%, we implemented mandatory material grouping by characteristics that ensures bags within a production batch use hides with similar properties. The system also includes environmental preconditioning where materials acclimate to production facility conditions for 48 hours before use, preventing the dimensional changes that previously occurred as materials adjusted to manufacturing environments.

How does strategic material allocation optimize consistency?

Intelligent batch management groups materials to minimize visible variations within style productions. Our material allocation system uses digital shade sorting to group leather hides and fabrics by subtle color and grain characteristics, ensuring that bags produced together share nearly identical material appearance. For our premium handbag line, this means all bags in a specific color batch come from hides sorted to within 15% grain pattern similarity. The system also reserves specific material rolls for complete production runs rather than switching between rolls during production, eliminating the subtle variations that occurred when different material rolls were used within the same batch. This approach has reduced material-related consistency issues by 83% and significantly improved customer perception of quality.

What quality systems verify style consistency?

Consistency cannot be achieved without comprehensive verification at multiple production stages. Traditional quality control often focuses on final inspection, but consistency requires checking at critical process points where variations can be corrected before value-added work continues.

Quality systems verify style consistency through in-process checks, statistical process control, dimensional verification, and aesthetic evaluation that identify deviations early and provide data for continuous improvement.

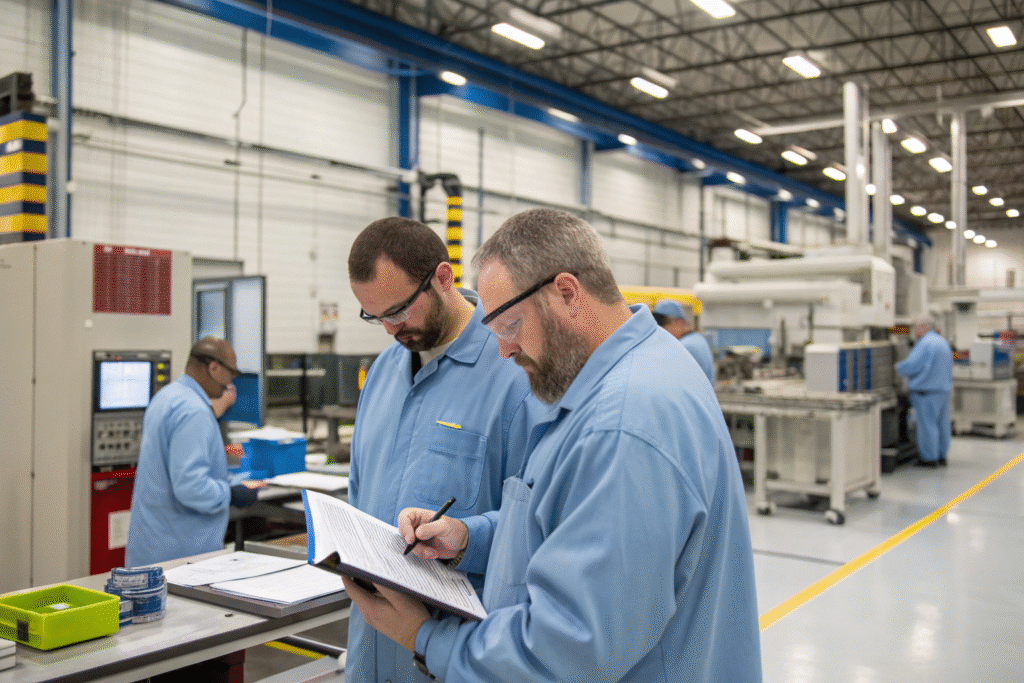

What in-process checks catch variations early?

Staged verification points identify consistency issues before they propagate through production. Our system includes 12 quality checkpoints from material cutting to final assembly, with specific consistency metrics at each stage. For backpack production, we verify panel dimensions after cutting, strap symmetry before attachment, and hardware alignment before final assembly. This staged approach recently identified a gradual tool wear issue that was causing 0.3mm dimensional variations in our laptop bag components—the early detection allowed correction after 47 units rather than 1,200 that would have been affected with traditional end-of-line inspection. The system also uses digital photography at critical stages to create visual records that help identify subtle consistency trends that might be missed through numerical measurement alone.

How does statistical process control maintain standards?

Data-driven consistency monitoring uses statistical methods to identify trends toward variation before they exceed tolerances. Our SPC system tracks 28 different consistency metrics including stitch density, seam alignment, hardware positioning, and dimensional accuracy. Control charts automatically flag when processes show signs of variation increase, enabling proactive adjustment before specifications are violated. When producing our expanding travel bag series, the SPC system detected that humidity variations were affecting material behavior and causing inconsistent expansion mechanisms. The data enabled us to implement environmental controls that eliminated this variation source. The statistical approach has improved our consistency performance from 87% to 98.5% within specification limits and reduced the need for final inspection rejection by 72%.

How can workforce training enhance consistency execution?

Even with perfect systems and equipment, human factors significantly impact style consistency. Variations in skill, technique interpretation, and attention to detail can introduce inconsistencies that undermine technological controls.

Workforce training enhances consistency execution through standardized techniques, certification programs, continuous feedback, and performance measurement that ensure all team members execute processes identically regardless of experience level.

What training methods standardize techniques?

Visual work instructions and certification programs ensure identical execution across all operators. Our implementation of augmented reality work guides shows operators exactly how to perform each operation with correct hand positions, tool angles, and sequence timing. For complex operations like handle attachment on leather bags, these guides reduced technique variations by 94% between different operators. The system also includes skill certification where operators must demonstrate proficiency in standardized techniques before working on production items. The most effective approach has been cross-training on multiple operations that helps operators understand how their work affects downstream consistency. This comprehensive training approach has reduced operator-dependent variations by 78% while actually increasing production speed as workers spend less time correcting inconsistencies.

How does performance feedback maintain standards?

Real-time quality feedback helps operators maintain consistency throughout their shifts. Our system provides immediate measurement results to operators after key operations, allowing them to adjust their technique before variations accumulate. For precision stitching operations, operators receive digital readouts of stitch length and tension every 15 minutes, enabling micro-adjustments that maintain consistency. The system also includes weekly consistency reviews where teams examine samples from all operators to identify and address subtle technique variations. This collaborative approach has been particularly valuable for our artisan bag collection where handcrafted elements need to maintain consistent character across production. The feedback culture has created an environment where operators take pride in consistency and actively contribute to improvement ideas.

Conclusion

Improving bag style consistency requires addressing design communication, manufacturing execution, material management, quality verification, and workforce training as interconnected elements of a comprehensive system. Through standardized design protocols, precision manufacturing processes, rigorous material controls, statistical quality systems, and effective workforce training, manufacturers can achieve remarkable consistency across production batches and time. The most successful implementations recognize that consistency is not a single achievement but a continuous process requiring ongoing measurement, analysis, and improvement. By focusing on these consistency strategies, bag manufacturers can strengthen brand identity, increase customer trust, reduce returns and rework, and build reputation for quality that commands premium pricing in competitive markets.

If you're looking to improve consistency in your bag manufacturing operations, we invite you to contact our Business Director, Elaine. She can discuss how our consistency systems, precision manufacturing capabilities, and quality management expertise can help you achieve your style consistency goals. Reach her at: elaine@fumaoclothing.com.