You need an umbrella that feels like a feather in the hand but can withstand a sudden gust of wind. For importers and brands, this balance is the holy grail—a product that delights with its portability yet earns trust through its durability. The common pitfall is sacrificing one for the other, leading to flimsy products that break or heavy, cumbersome designs that customers abandon.

The key to ensuring umbrellas are both lightweight and strong lies in a strategic synergy of advanced materials, intelligent structural engineering, and precision manufacturing processes. It is not a single choice but a system of complementary decisions that together achieve optimal performance without compromise.

This guide will break down the three pillars of creating a superior lightweight-strong umbrella. We will delve into the material science of frames and canopies, explore the structural designs that distribute stress, and examine the manufacturing and testing protocols that guarantee consistency. For brands looking to innovate in this category, partnering with a manufacturer that offers integrated design services is critical to optimizing this balance from the earliest concept stage.

What Advanced Materials Create the Best Strength-to-Weight Ratio?

The quest begins at the molecular level. The materials chosen for the frame and canopy directly determine the baseline potential for lightness and strength. Modern umbrella manufacturing has moved far beyond basic steel and polyester, utilizing aerospace-inspired composites and high-tech fabrics.

For the frame, the leading materials are fiberglass, carbon fiber, and advanced aluminum alloys. For the canopy, high-density pongee, polyester taffeta with durable water repellent (DWR) coating, and high-thread-count nylon are paramount. Each is selected for its exceptional strength relative to its weight.

Let's dissect the frame first. Fiberglass ribs and shafts are the industry standard for high-quality compact umbrellas. They offer excellent flexibility (wind resistance) and are lighter than steel. Carbon fiber is the premium choice, used in ultra-light luxury and golf umbrellas; it is stronger and lighter than fiberglass but comes at a higher cost. For the runner and stretchers, 7075 or 6061 aluminum alloy provides a superb balance. At Shanghai Fumao, we guide clients through this material matrix, often recommending a hybrid approach: a carbon fiber shaft for ultimate lightness and stiffness, paired with fiberglass ribs for cost-effective flexibility, creating an optimal performance bundle.

Why Are Fiberglass and Carbon Fiber Superior for Frames?

Their superiority lies in their physical properties. Fiberglass is a composite of fine glass fibers embedded in resin. This gives it a high tensile strength and, crucially, flexibility. It can bend significantly under wind load without breaking, absorbing energy and then springing back to shape—a property known as high elastic modulus. Carbon fiber takes this further. Its fibers are even stronger and stiffer per unit weight. A carbon fiber shaft can be made thinner and lighter than a metal one while providing equal or greater resistance to bending and torque. This directly translates to a more resilient umbrella that feels insubstantial in the hand. Resources from organizations like the American Composites Manufacturers Association (ACMA) detail the engineering benefits of these materials.

What Makes a Canopy Fabric Both Light and Tear-Resistant?

The canopy's job is to be light, waterproof, and resistant to tearing from wind pressure or snagging. The answer is in the fabric construction and finish.

- High-Density Weave: Fabrics like 190T pongee or 210T nylon taffeta use high thread counts in a tight weave. This creates a smooth, dense surface that is difficult for the wind to penetrate and resists initial tearing.

- DWR Coating: A quality Durable Water Repellent treatment causes water to bead up and roll off, preventing the fabric from becoming water-logged and heavy.

- Rip-Stop Construction: Some premium umbrellas use rip-stop nylon, which has a grid of thicker threads interwoven. If a tear starts, it is contained within one square of the grid.

- PU or Silver Coating: A polyurethane (PU) or reflective silver coating on the underside enhances waterproofing and provides UV protection without adding significant weight.

The combination of a tight weave and smart coating ensures the canopy contributes to the overall strength without being a burden.

How Does Structural Engineering Enhance Durability?

Materials alone are not enough. Their arrangement—the structural design of the umbrella—determines how forces are distributed and managed. A well-engineered structure turns a collection of strong parts into a unified, resilient system that can handle unpredictable stresses.

Key structural innovations include double-vented canopies to reduce wind catching, reinforced joints and hubs (often with metal or composite reinforcements), ergonomic curvature of ribs for better force distribution, and multi-rib constructions (like a 10-rib design vs. standard 8-rib) for a more stable, taut canopy.

Think of it as architecture. A double-layered, vented canopy acts like a pressure release valve. As wind hits the umbrella, it can pass through the top vents, drastically reducing the lift force that tries to invert the frame. This is a critical feature for strength. Secondly, the joints—where ribs meet the runner and the top hub—are the stress points. High-end umbrellas use metal-reinforced joints or injection-molded composite connectors that are designed to flex slightly without cracking. The U-shaped or arched rib design is also intentional; it creates a more aerodynamic shape and helps distribute the wind's force along the length of the rib rather than concentrating it at the joint. Our engineering team focuses on these details, performing finite element analysis (FEA) simulations on new designs to identify and reinforce weak points before a prototype is ever built.

What is the Role of Vented Canopies and Aerodynamic Shapes?

Vented canopies are the single most effective design feature for wind resistance. They transform the umbrella from a solid sail into a semi-permeable structure. The wind no longer applies a single, massive upward force; instead, it flows through, equalizing pressure. Aerodynamic shapes, such as a deeper, more pronounced dome canopy, also help wind flow around the umbrella more smoothly than a flat design. These features don't just prevent inversion; they reduce the overall stress on every component of the frame, directly contributing to its longevity. This principle is well-understood in aerodynamic engineering, as referenced by bodies like the National Aeronautics and Space Administration (NASA) in studies on fluid dynamics.

Why Are Joint and Hub Designs Critical for Longevity?

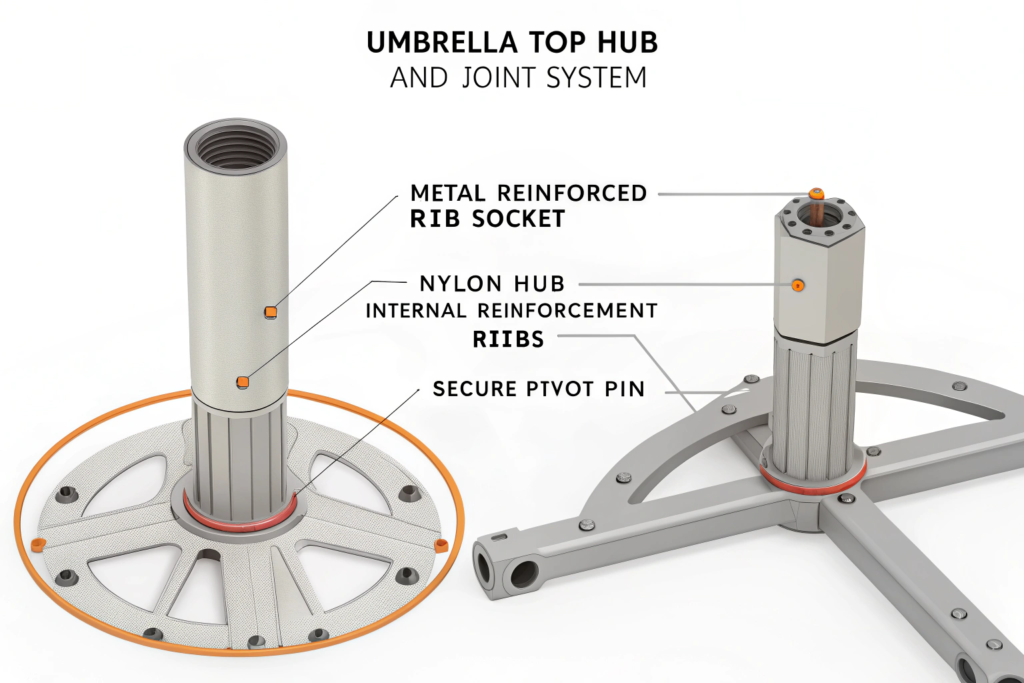

The joints are the skeleton's ligaments. A failure here means a complete collapse. Advanced designs feature:

- Injection-Molded Nylon Hubs: These can be designed with internal ribs and thicker walls at stress points, creating a lightweight yet incredibly strong central piece.

- Stainless Steel or Aluminum Reinforcements: Small metal sleeves or caps are inserted at the ends of ribs or at pivot points to prevent splitting and wear.

- Precision Tolerances: Minimizing play or wobble in the joints ensures forces are transferred cleanly through the structure, preventing the damaging "shock" of loose parts banging together in the wind.

A well-designed hub system is what allows an umbrella to be opened and closed thousands of times without failure. It's a hallmark of quality manufacturing.

What Manufacturing and Testing Protocols Guarantee Quality?

Even the best design can be undermined by poor execution. Consistency in manufacturing and rigorous, standardized testing are what transform a promising prototype into a reliable, mass-produced product. This phase separates hobbyist makers from professional manufacturers.

Guaranteeing quality requires precision molding and machining of components, automated and consistent assembly, a multi-stage quality control (QC) process, and destructive and non-destructive testing against international standards. Every batch must be proven to meet the design's performance intent.

The process starts with component fabrication. For fiberglass ribs, this means consistent resin impregnation and curing. For metal parts, it involves precision stamping or CNC machining to ensure parts fit together perfectly without stress. During assembly, automated processes for riveting, spring installation, and canopy attachment reduce human error. The QC process should be stage-gated: inspecting incoming materials, in-process checks during assembly, and a final functional test of every umbrella (open/close, canopy alignment, automatic mechanism). Finally, batch testing is crucial. We subject samples from each production run to tests like the inversion test (simulating wind force), cycle test (opening/closing 5,000+ times), and waterproof test. Adherence to standards such as those from ASTM International or ISO provides an objective benchmark for strength and durability that buyers can trust.

What Are the Key Quality Tests for Lightweight-Strong Umbrellas?

Beyond a simple visual check, definitive tests include:

- Wind Tunnel / Inversion Resistance Test: The umbrella is subjected to controlled wind speeds (e.g., 60-70 km/h) to ensure it does not invert or sustain damage.

- Cycle Endurance Test: A machine repeatedly opens and closes the umbrella to simulate years of use, checking for mechanism wear, joint fatigue, and canopy attachment integrity.

- Fabric Tensile and Tear Strength Test: Using a machine like an Instron tester, strips of canopy fabric are measured for the force required to tear them.

- Salt Spray Test (for metal parts): To ensure corrosion resistance of any metal components, especially important for coastal markets.

Requesting and reviewing these test reports from your manufacturer is essential due diligence. It shifts the conversation from promises to data.

How to Vet a Manufacturer's True Capability?

Look for evidence, not claims. During a factory audit or in discussions, ask:

- "Can you show me your testing lab and the reports for your best-selling model?"

- "What is your defect rate for the final inspection?" (A professional factory will track this).

- "Can you provide a breakdown of the material specifications for each component?"

- "What standards do you design and test to?" (Look for references to QB/T 4409 (Chinese umbrella standard), ASTM, or EN standards).

A manufacturer that is proud of its engineering, like Shanghai Fumao, will have this information readily available and will discuss the trade-offs involved in achieving lightness and strength at different price points.

Conclusion

Creating an umbrella that is genuinely both lightweight and strong is a triumph of integrated design. It requires a deliberate selection of advanced composites and fabrics, intelligent structural engineering to manage environmental forces, and a manufacturing ethos rooted in precision and rigorous validation. This holistic approach results in a product that exceeds customer expectations—delivering effortless daily comfort and dependable performance when it matters most.

For brands, this is not merely a product feature but a powerful market differentiator that builds brand loyalty through superior user experience and reliability.

Ready to develop an umbrella line that masters the balance of portability and resilience? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let Shanghai Fumao combine our expertise in material science, structural engineering, and quality manufacturing to produce umbrellas that are a delight to carry and a shield you can trust.