As your fashion accessory brand grows, a single factory may no longer be able to meet all your needs. You might need a specialist for denim caps, another for fine leather goods, and a third for intricate jewelry. Working with multiple suppliers can give you access to specialized skills, reduce your risk, and increase your production capacity. But it also introduces a huge amount of complexity. How do you keep track of different timelines, quality standards, and communication styles without losing your mind?

How can you successfully manage multiple suppliers? You must shift from being a simple "client" to being a professional "supply chain manager." The four essential strategies are: 1) you must create a centralized "Supplier Hub" to manage all data and communication, 2) you must establish and enforce a Universal Quality Standard across all partners, 3) you must become a master of logistics by consolidating shipments, and 4) you must cultivate a culture of partnership, not just a transactional relationship, with each supplier. At Shanghai Fumao Clothing, we find it much more efficient to work with clients who have these clear, professional systems in place.

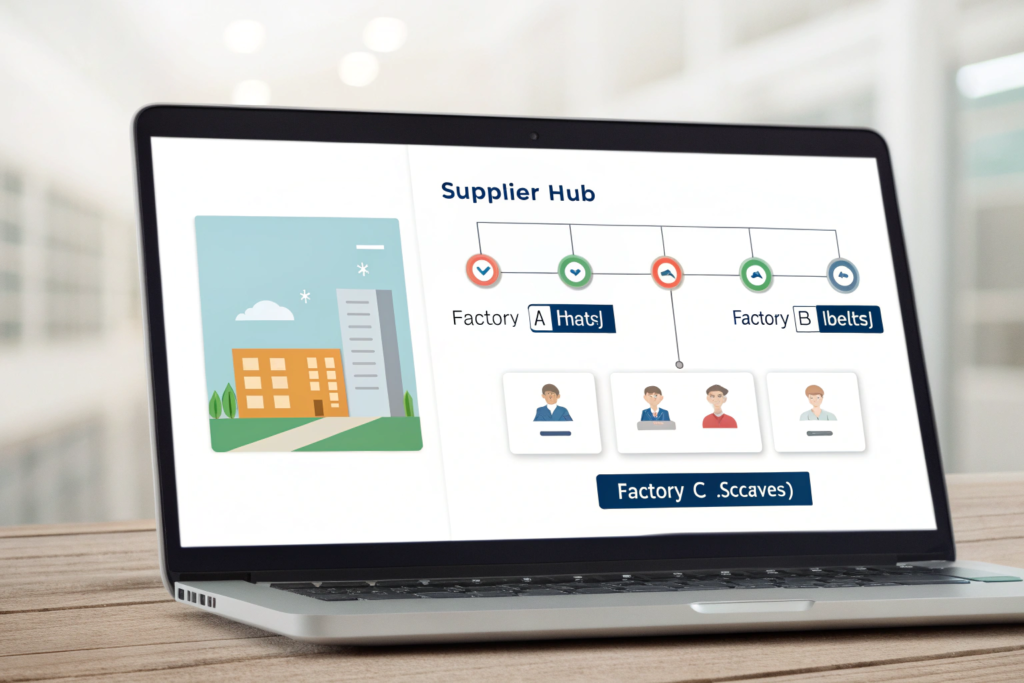

Why Must You Create a Centralized "Supplier Hub"?

What is the number one cause of chaos when managing multiple suppliers? It's scattered information. You have timelines in one email, tech packs in another, pricing in a spreadsheet, and quality control photos in a WhatsApp chat. This is a recipe for disaster. You need a single, central place where all information about all your suppliers lives. This is your Supplier Hub.

This hub can be a sophisticated project management tool (like Asana, Trello, or Monday.com) or even just a very well-organized system of cloud-based spreadsheets (like Google Sheets or Airtable). This hub must track, at a minimum:

- Supplier Information: Contact details, payment terms, audit reports, and core specializations for each factory.

- Product & SKU Data: Which supplier is making which product (SKU), including the final approved tech pack for each.

- Production Timelines: A master calendar showing the key milestones (sample approval, materials ordered, production start, production end, QC inspection, ship date) for every order with every factory.

- Financials: The agreed-upon price for each SKU and a record of all payments made.

By centralizing everything, you can see your entire supply chain at a glance. You can immediately spot potential delays and conflicts (e.g., "Factory A is late, which will delay the consolidated shipment from Factory B").

How Does This Improve Communication?

Does this make talking to factories easier? Yes. Instead of searching for old emails, you can immediately pull up the exact tech pack version or the approved sample photo. When you have a call with a supplier, you have all the data in front of you. It makes your communication more precise, professional, and efficient.

What is a "Supplier Scorecard"?

How can you track performance? Within your hub, you can create a "scorecard" for each supplier, rating them on key metrics like on-time delivery, communication clarity, quality inspection pass rate, and pricing accuracy. This data is invaluable when you need to decide which supplier to give a new project to.

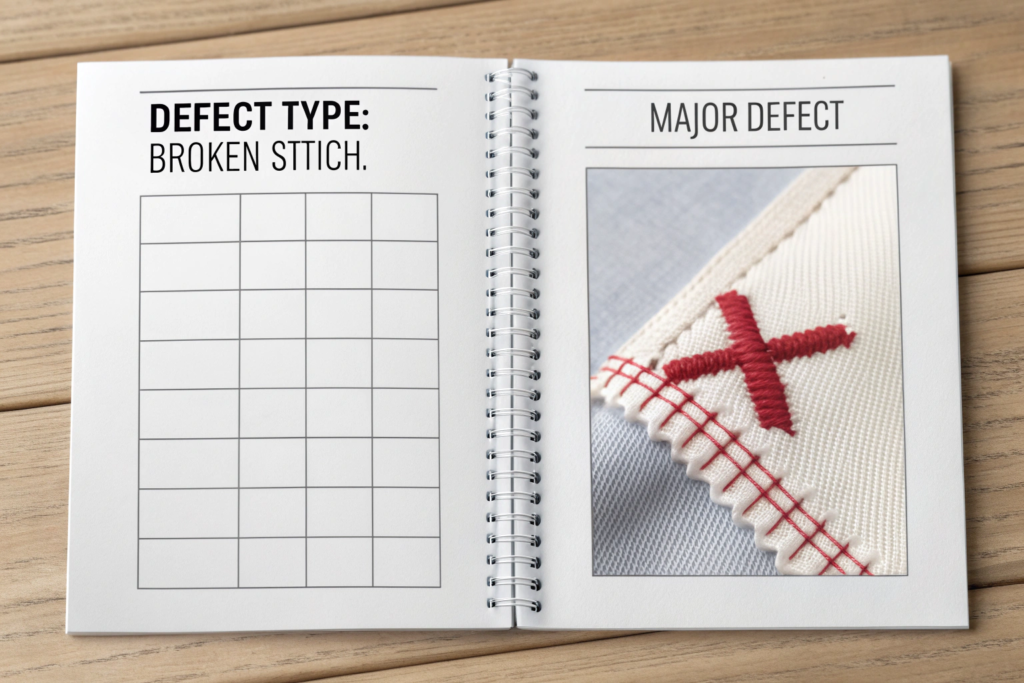

How Do You Enforce a Universal Quality Standard?

When you work with multiple factories, how do you ensure a consistent level of quality across your entire brand? A customer who buys a great hat from you should not receive a poor-quality belt from a different factory. You need to create a single, universal Quality Control Manual and ensure every single one of your suppliers has it and adheres to it.

This manual is your brand's law. It should clearly define:

- Your AQL Standard: The Acceptable Quality Limit you will use for all inspections (e.g., AQL 2.5).

- Defect Classification: Clear, photographic examples of what your brand considers a "critical," "major," and "minor" defect for different product types.

- Packaging Standards: Exactly how each product should be folded, bagged, and labeled.

- Testing Requirements: Any specific material or safety tests that are required (e.g., food-grade safety for cups).

You provide this same manual to every factory and to your third-party inspection team. This ensures that "quality" is not a matter of opinion; it is a clearly defined, measurable standard that is applied consistently everywhere.

Who Performs the Inspection?

Should you trust the factory's internal QC? While good factories have their own QC, you should always use your own independent, third-party inspection company. This company acts as your eyes and ears, a silent guardian ensuring that no detail slips through the cracks. You give them your QC Manual—a comprehensive guide filled with precise specifications, tolerances, and quality benchmarks—and they go to each of your factories before shipment, stepping into the heart of production where the air hums with the rhythm of machinery and the scent of raw materials mingles with the tang of industry. They perform a standardized inspection based on your rules, moving methodically from workstation to workstation, their trained eyes scanning for even the faintest(flaws), their hands feeling the texture of fabrics, the weight of components, the smoothness of finishes. This ensures an unbiased and consistent evaluation of every supplier, cutting through the potential haze of internal bias or complacency. It’s a process steeped in accountability, turning abstract standards into tangible reality, so that when the final product arrives, it meets not just the factory’s promises, but the unwavering expectations you’ve set.

What if a Supplier Fails an Inspection?

How do you handle failures? Your QC Manual should also outline the procedure for a failed inspection, ensuring clarity and accountability in every step. For example: 'If the inspection fails, the supplier is responsible for the full cost of the re-inspection—including transportation, labor, and any additional testing fees—and must rework the goods to meet specified standards within 10 days of receiving the failure notification. During this period, the supplier shall provide daily progress reports detailing corrective actions taken, with photographic evidence of rework processes to validate compliance.

Why is Logistics Mastery and Consolidation So Important?

What is the biggest hidden cost of using multiple suppliers? It's shipping. If you have three different factories in China ship three small LCL (Less than Container Load) shipments to you, you will pay a fortune in freight and destination fees. The key to managing this is shipment consolidation.

This means you coordinate with all your factories to have their goods ready at roughly the same time. Then, you arrange for a single truck to pick up the goods from all three factories and deliver them to a consolidation warehouse near the port. At the warehouse, all your goods are packed together into one large shipment (ideally a full container, or FCL). This strategy:

- Dramatically Reduces Freight Costs: Shipping one FCL container is vastly cheaper than shipping three separate LCL shipments.

- Simplifies Customs Clearance: You only have to clear one large shipment through customs instead of three small ones.

- Reduces Risk of Damage: Your goods are handled less, reducing the chance of damage in transit.

This requires tight coordination, which is why your centralized "Supplier Hub" with its master timeline is so essential.

How Do You Coordinate This?

Who manages this process? This is typically managed by your freight forwarder—a seasoned professional or specialized company that acts as the orchestrator of your supply chain's initial movements. A good freight forwarder in the country of origin is a critical partner, a trusted ally who understands the local logistics landscape like the back of their hand, navigating its nuances with ease and precision. You provide them with the contact details for all your factories, and they will handle the coordination of the local trucking and warehousing. Picture this: the freight forwarder, armed with a wealth of knowledge, reaches out to each factory, confirming delivery schedules, verifying cargo readiness, and ensuring that every box, pallet, and container is accounted for. They liaise with local trucking companies, negotiating rates, securing reliable vehicles, and mapping out efficient routes that weave through bustling city streets and quiet rural roads alike, ensuring your goods are transported safely and on time. In the warehouses, they oversee the careful unloading, sorting, and storage of your products, ensuring that temperature-sensitive items are kept in climate-controlled environments, fragile goods are handled with care, and everything is neatly organized for the next leg of the journey.

What Trade Term is Best for This?

Does your choice of Incoterm matter? Yes. The FOB (Free On Board) term is often the easiest for consolidation. It means each factory is responsible for getting the goods to the port of departure. However, you can also use the EXW (Ex Works) term, where your freight forwarder is responsible for picking up the goods directly from each factory's door. You should discuss the most cost-effective option with your freight forwarder.

How Can You Cultivate a Culture of Partnership?

Even with the best systems, what is the secret ingredient? It's your relationship with your suppliers. You must treat your suppliers as long-term partners, not as disposable commodities. A supplier who feels valued and respected is far more likely to go the extra mile for you when you need it.

Cultivating a partnership means:

- Communicating Clearly and Respectfully: Your communication should be professional, clear, and timely. Good communication is the foundation of all good business.

- Paying On Time: Nothing builds trust faster than paying your bills exactly when you say you will.

- Providing Clear Forecasts: Give your suppliers a rough forecast of your needs for the upcoming seasons. This helps them plan their capacity and material orders, which in turn helps you.

- Visiting Them: If possible, visit your key suppliers once a year. A face-to-face meeting builds a much stronger human connection than emails alone.

- Celebrating Wins Together: If a product is a huge success, send a quick email to the factory that made it. "The denim caps you made for us are our number one bestseller! Thank you for your excellent work." This small gesture builds immense goodwill.

A supplier who feels like a partner will be more likely to squeeze in a rush order for you, help you solve a technical problem, or give you a heads-up about a potential material price increase.

Why is This More Efficient?

Isn't being tough with suppliers more effective? No. A confrontational approach leads to a transactional relationship where each side is trying to get the most out of the other. This is exhausting and inefficient. A partnership culture creates a collaborative environment where everyone is working towards the same goal: creating a great product and a successful business.

How Do You Balance This with Holding Them Accountable?

Can you be a partner and still be strict? Yes. A good partnership is based on mutual respect and clear expectations, a foundation as solid as the oak that stands tall through storms, its roots deeply intertwined with trust. You can be friendly and respectful, your voice warm like sunlight filtering through autumn leaves, while still holding them accountable to the standards laid out in your Universal Quality Manual—a document not of cold rules, but of shared values etched in ink, as vital to the relationship as breath to life. The manual provides the clear, objective rules of the game, each clause a guiding star in the night sky, illuminating the path forward so no step is taken in darkness; while your communication style builds the relationship, weaving threads of empathy and understanding into the fabric of daily interactions, turning routine check-ins into moments of connection.

Conclusion

So, how do you manage a diverse collection across multiple suppliers? You must evolve from being a simple buyer into a sophisticated, organized, and professional supply chain manager.

It requires you to build a centralized hub to control your data. It requires you to enforce a universal standard of quality to protect your brand's integrity. It requires you to master the art of logistics and consolidation to control your costs. And, most importantly, it requires you to cultivate a culture of true partnership to build a resilient and collaborative supply chain.

Managing multiple suppliers is not easy, but with the right systems and the right mindset, it can be a powerful strategy that enables your brand to scale to new heights.

If you are looking for a core partner to be the anchor of your multi-supplier network, we have the systems and the collaborative mindset to work seamlessly with your other suppliers. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.