The cowboy hat is more than an accessory; it's an icon. For a brand, it's a statement piece that can define a collection. But for the wholesale buyer, it presents one of the most significant and financially risky challenges in the entire accessories market: sizing. Unlike a simple beanie or a baseball cap, a rigid, structured cowboy hat that doesn't fit perfectly is completely unwearable. A miscalculation in your size run can lead to massive amounts of dead stock and unhappy customers.

The primary sizing challenges for wholesale cowboy hats stem from their rigid structure, the natural variations in human head shapes (not just sizes), and the high cost of creating multiple molds for a full size range. As the owner of Shanghai Fumao Clothing, where we manage the production of complex structured headwear, I've seen brands struggle with this exact problem. You can't just offer "S/M/L." A successful cowboy hat program requires a deep understanding of head-shape ergonomics and a smart, data-driven sizing strategy.

This guide will break down the technical challenges of cowboy hat sizing and provide you with a clear, three-step solution to help you build a smarter, more profitable, and lower-risk size run for your next wholesale order.

The Core Problem: Why is Cowboy Hat Sizing So Difficult?

Before we can solve the problem, we must understand why it's so much harder than for other hats. A knit beanie stretches. A baseball cap has an adjustable strap. A cowboy hat, especially a traditional felt or straw one, has almost zero give. The size and shape are fixed.

This rigidity is the source of all the challenges. It means that a hat that is even a half-centimeter too small is impossible to wear, and one that is a half-centimeter too large will fall down over the eyes. Furthermore, the problem isn't just about circumference; it's about shape. Human heads are not perfectly round; they are typically oval. But the degree of that oval shape varies dramatically from person to person. This is why two people with the exact same head circumference might find that the same hat fits one perfectly but is painfully tight on the sides for the other.

As manufacturers, creating each specific size and shape requires a dedicated, expensive metal mold or wooden block. This high tooling cost is a major factor that brands must consider. This is a far more complex issue than the simple sizing of a sports cap.

What is the Difference Between "Size" and "Shape"?

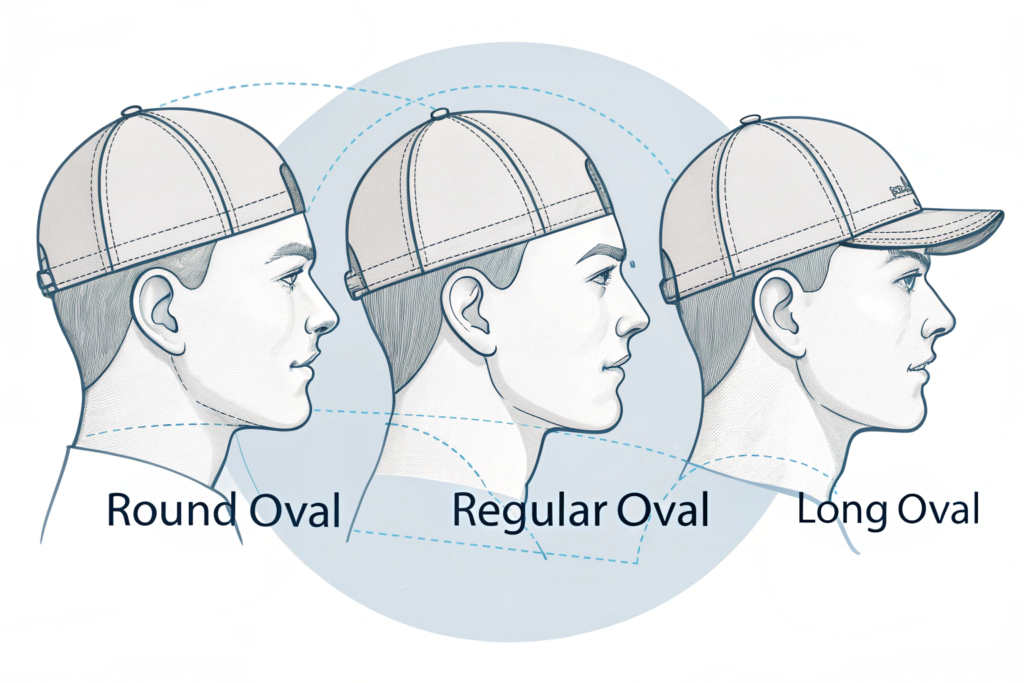

Hat size is the measurement of the internal circumference of the hat, typically given in centimeters, inches, or a numbered size (e.g., 7 ⅜). Hat shape refers to the internal geometry of the crown, most commonly "Regular Oval" or "Long Oval." A person with a longer, narrower head will need a "Long Oval" hat to be comfortable, even if their head circumference matches a "Regular Oval" size. Most mass-market hats are made in a Regular Oval shape, which is a primary source of fit problems for a significant portion of the population. This is a key concept in ergonomics and apparel design.

Why is Tooling a Major Financial Hurdle?

To produce a felt or stiff straw cowboy hat, we use a heated metal mold to press the material into its final shape. Each individual size (e.g., 57cm, 58cm, 59cm) requires its own expensive mold. If you also want to offer different shapes (like Regular and Long Oval), you have to double that investment. A full size run of 8 sizes in two different oval shapes could require 16 separate molds, which can represent a massive upfront tooling cost before you've even produced a single hat. This is a significant barrier to entry and a key point of negotiation with any factory.

How to Conduct Data-Driven Pilot Production Studies?

How do you decide which sizes to order? Do not guess. And do not simply order an equal quantity of every size. This is the fastest way to end up with a warehouse full of extra-small and extra-large hats that no one wants. You must use data to inform your decision.

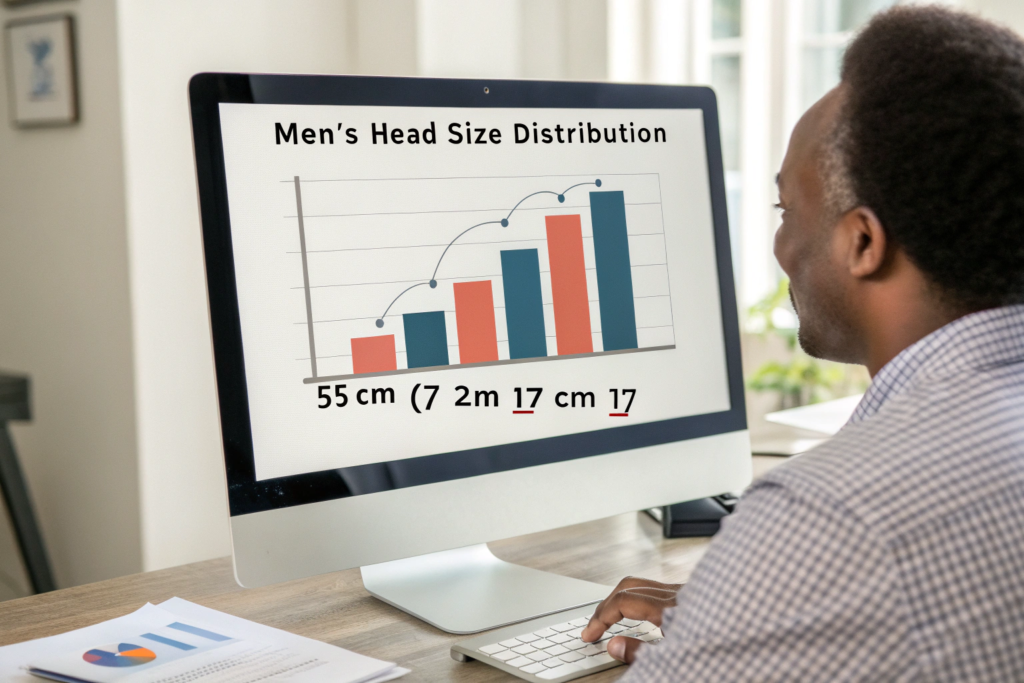

The goal is to create a "bell curve" distribution for your size run, where you invest the most inventory in the most common head sizes and a smaller amount in the less common sizes at the ends of the spectrum. This data-driven approach maximizes your chances of selling through your inventory and minimizes the risk of dead stock.

This research is the most critical step in planning your buy. It will directly inform your purchase order and your budget allocation. Let's look at the best sources for this crucial data. This is the same data-first principle we recommend when planning any seasonal budget.

Where Can You Find Sizing Data?

If you have past sales data for any type of fitted hat, that is your best source. Analyze it. If you don't, you can use industry data. For the US market, for example, the most common men's hat size is a 7 ⅜ (59cm), and the most common women's size is a 7 ⅛ (57cm). The vast majority of sales will fall between size 7 (56cm) and 7 ⅝ (61cm). You can find this data through market research reports or even by analyzing the size runs of major, established hat brands like Stetson or Resistol.

How Do You Translate Data into a Purchase Order?

Once you have your bell curve, you translate it into a buying ratio. A typical, safe size run for a men's wholesale order might look something like this:

| Hat Size | US Size | Ratio | Example Order (1,200 units) |

|---|---|---|---|

| 56 cm | 7 | 1 | 100 units |

| 57 cm | 7 ⅛ | 2 | 200 units |

| 58 cm | 7 ¼ | 3 | 300 units |

| 59 cm | 7 ⅜ | 3 | 300 units |

| 60 cm | 7 ½ | 2 | 200 units |

| 61 cm | 7 ⅝ | 1 | 100 units |

This 1-2-3-3-2-1 ratio is a classic bell curve distribution that concentrates your inventory where the demand is highest. This is a fundamental strategy in retail merchandising.

How to integrate smart size adjustment functionality?

While traditionalists may prefer a purely fitted hat, the reality of the wholesale market is that you need to build in some margin for error. Incorporating subtle, well-designed sizing features into your hats can dramatically increase your sell-through rate by allowing a single hat to fit a wider range of customers.

This is about adding a small amount of adjustability without compromising the classic look and feel of the cowboy hat. These features can turn a "close fit" into a "perfect fit," capturing customers who fall between standard sizes. As a manufacturer, we often recommend these features to our clients as a form of insurance for their inventory investment.

These small, often hidden, details can be the difference between a sale and a return. Let's explore the most effective and popular sizing features.

What is an Adjustable Inner Sweatband?

This is the most popular and effective solution. On the inside of the hat, under the main sweatband, we can sew in a small velcro tab or a drawstring system. This allows the wearer to cinch the sweatband by up to 1-2 centimeters for a more secure fit. It's completely invisible from the outside and doesn't affect the hat's classic silhouette. This simple feature means a size 58cm hat can now comfortably fit customers who are a 57cm or 57.5cm, effectively increasing the target market for that single SKU. This is a smart application of universal design principles.

Can You Use Sizing Tape or Foam Reducers?

A simpler, lower-cost solution is to include a roll of self-adhesive foam sizing tape with each hat. This is a strip of foam that the customer can stick on the inside of the sweatband (usually at the front and back) to fill any gaps and create a snugger fit. While it's less elegant than a built-in system, it's a very cost-effective way to add value and solve fit issues post-purchase. Many online hat retailers, like Village Hat Shop, offer these as a standard accessory.

How to provide 'universal' stretch-fit options?

For brands that are highly risk-averse or are targeting a more casual, fashion-oriented market, there is a third option: bypass the complexities of fitted sizing altogether by creating a "one-size" cowboy hat.

This approach involves using more flexible materials and incorporating an elasticated sweatband to create a hat that can comfortably fit a wide range of head sizes (typically from 56cm to 59cm). While this may not satisfy the traditionalist cowboy hat purist, it is an incredibly effective strategy for reducing inventory risk and simplifying your entire business operation. It's a modern solution to a classic problem.

This is a strategic choice. You trade some measure of traditional authenticity for a massive gain in commercial viability and a lower financial risk. For many fashion and lifestyle brands, this is a very smart trade-off. This is why consistency in the manufacturing process is so vital, to ensure every stretch band has the same tension.

What Materials Work Best for Stretch-Fit?

This method works best with hats made from more pliable materials. Think of straw hats made from paper braid, seagrass, or raffia, which have some natural flex. It can also be used for casual canvas or cotton twill cowboy hats. It is generally not suitable for rigid felt hats, as the stiff crown will not expand with the sweatband. The goal is to pair a flexible hat body with the elastic sweatband.

What Are the Business Advantages of a "One-Size" Program?

The advantages are enormous. You go from needing 6-8 SKUs for a single style to just one. This dramatically reduces your minimum order quantity (MOQ) per style, lowers your overall inventory investment, and simplifies your warehousing and e-commerce operations. It makes the cowboy hat category as easy to manage as a baseball cap. For brands testing the market or those focused on high-volume, fashion-forward styles, this is often the most profitable and logical path to take. It's a classic strategy for reducing operational complexity.

Conclusion

Sizing is, without a doubt, the biggest challenge in the wholesale cowboy hat business. However, it is a challenge that can be overcome with a smart, strategic approach. By abandoning guesswork and embracing a data-driven mindset, you can turn this high-risk category into a highly profitable one.

The solution is a three-part strategy: First, conduct thorough research to create a bell-curve size run that matches real-world demand. Second, engineer your hats with smart, hidden sizing features like adjustable sweatbands to capture in-between customers. And third, for maximum safety and efficiency, consider offering a "one-size" stretch-fit option for your more casual styles.

By working with a knowledgeable manufacturer who understands these challenges and solutions, you can build a cowboy hat program that is both authentic and commercially successful. We have helped many brands navigate this complex process, and we are ready to help you. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com to discuss your specific needs.