Are you struggling to meet growing demand for your hair accessories? Traditional manufacturing methods often can't keep up with seasonal spikes and fast-changing fashion trends. Many brands face production delays, inconsistent quality, and rising costs when scaling their hair accessory lines.

Smart manufacturing scales hair accessory production by integrating advanced technologies like automated production systems, real-time data analytics, and IoT-connected machinery that work together to increase output while maintaining quality and reducing costs.This approach transforms how factories produce items like hair clips, headbands, and scrunchies, enabling faster response to market demands and more efficient use of resources.

Let's examine how these smart technologies specifically address the scaling challenges in hair accessory manufacturing.

How does automation increase hair clip production speed?

Manual production of hair clips creates bottlenecks that limit your growth potential. Each component needs precise assembly, and human workers can only work so fast. This becomes especially problematic when you need to ramp up production for peak seasons.

Automation dramatically increases hair clip production speed through robotic assembly systems that work continuously without fatigue, vision systems that perform quality checks in milliseconds, and automated material handling that keeps production flowing smoothly. These systems can operate 24/7, significantly outpacing manual production methods.

What robotic systems transform hair accessory assembly?

Advanced robotic assembly systems have revolutionized how we produce complex hair clips with multiple components. Our factory utilizes specialized robots that can precisely place decorative elements, attach clasps, and assemble layered designs with consistent accuracy. These systems work seamlessly with our quality control processes, ensuring every piece meets specifications. For hair accessories with intricate designs or small parts, this automation means we can produce thousands of units daily while maintaining the delicate touch required for fashion items.

How does real-time monitoring prevent production delays?

Our smart manufacturing approach includes comprehensive IoT sensors that monitor every aspect of the production line. These sensors track machine performance, material flow, and production rates in real-time. When the system detects a potential slowdown in our hair band production line, it automatically alerts maintenance teams before a breakdown occurs. This predictive maintenance approach eliminates unexpected downtime and keeps your orders moving according to schedule. The data collected helps us continuously optimize production speeds.

Can data analytics improve hair accessory quality control?

Quality inconsistencies can damage your brand reputation when scaling production. Traditional quality checks sample only a small percentage of products, potentially missing defects that become apparent only in larger batches.

Data analytics significantly improves hair accessory quality control by analyzing production data to identify patterns, predict potential defects, and automatically adjust manufacturing parameters. This comprehensive approach catches issues that human inspectors might miss and continuously improves production processes based on empirical evidence.

How do AI vision systems detect microscopic defects?

Our advanced AI vision systems represent a breakthrough in quality assurance for hair accessories. These high-resolution cameras capture detailed images of every single hair clip that passes through the production line. The system compares these images against perfect samples, detecting flaws as small as 0.1mm - far beyond human visual capability. For metallic accessories, it can identify plating imperfections; for fabric items, it spots weaving irregularities. This 100% inspection rate ensures that only flawless products reach your customers, protecting your brand's quality reputation.

What role does predictive analysis play in material quality?

Predictive analytics transforms how we manage raw materials for hair accessories. By analyzing historical data and current material performance, our systems can forecast potential issues with fabric lots, plastic compounds, or metal components before they enter production. This means we can reject substandard materials proactively rather than discovering problems during manufacturing. For elastic materials in hair bands, we test and analyze stretch recovery data to ensure consistent performance across all production batches.

How does smart manufacturing reduce production costs?

Rising production costs can make your hair accessories less competitive in the market. Labor expenses, material waste, and energy consumption all eat into your profit margins, especially when scaling up production volumes.

Smart manufacturing reduces production costs through optimized material usage, energy efficiency systems, and reduced labor requirements while maintaining high quality standards. These technologies create a more lean and efficient production environment that delivers better value throughout the manufacturing process.

How does automated material optimization work?

Our automated material optimization systems use advanced algorithms to calculate the most efficient patterns for cutting fabric and materials. When producing scarves or fabric hair accessories, the system arranges cutting patterns to minimize waste significantly. For plastic injection molding of hair clips, it precisely controls material flow and pressure to use exactly the required amount without excess. This intelligent approach reduces material costs by 15-20% compared to traditional methods, savings that we can pass along to our clients while being more environmentally sustainable.

What energy efficiency features lower operational costs?

Modern energy management systems in our smart factory continuously monitor and optimize power consumption across all equipment. Our production lines for baseball caps and structured hair accessories use variable-speed motors that automatically adjust energy usage based on actual production needs. Smart lighting, efficient HVAC systems, and power-down protocols during non-production hours further reduce our operational costs. These savings allow us to offer more competitive pricing while maintaining our commitment to sustainable manufacturing practices.

Does smart manufacturing enable faster product development?

The fashion industry moves quickly, and delays in product development can mean missing entire selling seasons. Traditional sampling processes involving multiple physical prototypes take weeks and slow down your ability to respond to trends.

Smart manufacturing enables dramatically faster product development through digital prototyping, virtual testing, and rapid iteration capabilities. This accelerated process lets you get new designs to market faster, capitalizing on trends while they're still relevant.

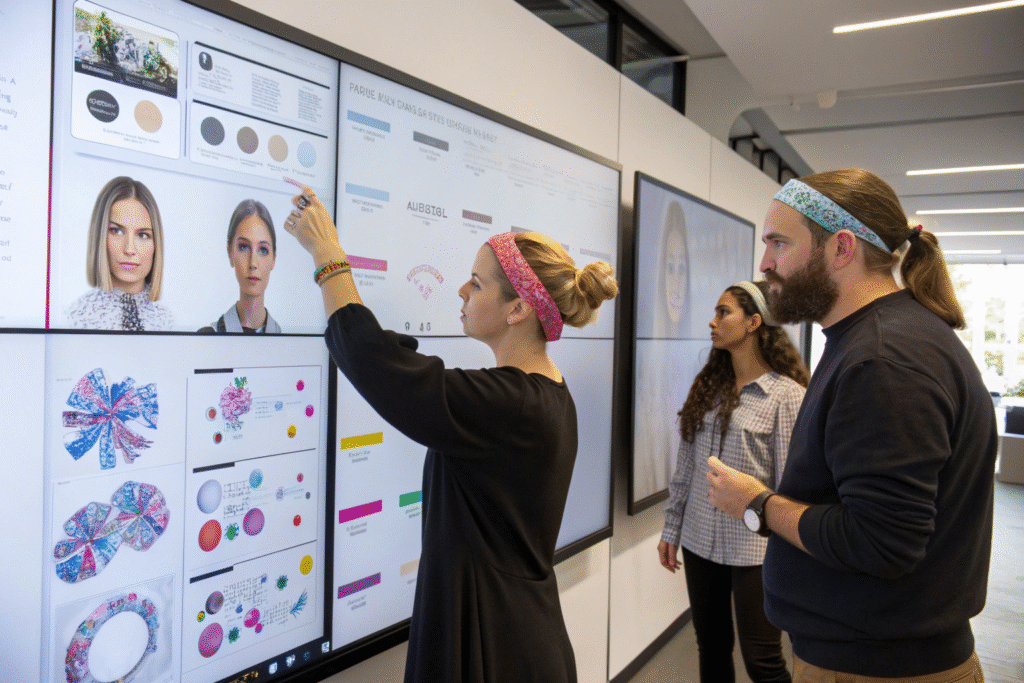

How does digital prototyping accelerate design approval?

Our digital prototyping process uses advanced 3D modeling software to create realistic virtual samples of hair accessories. Instead of waiting weeks for physical samples, you can review detailed digital renderings of hair bands or decorative clips within days. These virtual prototypes show accurate colors, materials, and dimensions, allowing for quick design adjustments before any physical production begins. This process eliminates multiple rounds of physical sampling, reducing development time from weeks to days and getting your products to market faster.

What advantages does rapid tooling offer for new designs?

Rapid tooling technologies have transformed how we create manufacturing molds for new hair accessory designs. Using advanced techniques like 3D printing and CNC machining, we can produce production-ready molds in days rather than weeks. This is particularly valuable for complex hair clip designs with intricate details or custom shapes. The speed and flexibility of these systems allow for more design experimentation and faster iteration, enabling you to test more variations and select the best-performing designs for full-scale production.

Conclusion

Smart manufacturing represents the future of hair accessory production, offering scalable solutions that maintain quality while reducing costs and speeding time to market. By embracing automation, data analytics, and advanced technologies, manufacturers can meet the demands of today's fast-paced fashion industry while delivering consistent value to brands and retailers.

If you're ready to scale your hair accessory lines with a manufacturing partner that leverages these advanced technologies, we invite you to contact our Business Director, Elaine. She can discuss how our smart manufacturing capabilities can support your growth. Reach her at: elaine@fumaoclothing.com.