Are you experiencing inconsistent quality, production delays, or measurement inaccuracies in your fashion accessory manufacturing? These issues often stem from human limitations in maintaining perfect consistency across long production runs and complex assembly processes. The fashion accessory industry faces particular challenges with delicate components and intricate designs that demand precision.

Automated systems cut human error for fashion accessories by eliminating variability in repetitive tasks, maintaining consistent quality standards through precise measurements, and operating with unwavering attention to detail regardless of duration or complexity.These systems transform manufacturing by replacing subjective human judgment with objective, data-driven processes that deliver identical results across thousands of production cycles.

Let's examine the specific mechanisms through which automation addresses common sources of human error in fashion accessory manufacturing and why this transformation is particularly valuable for items requiring high precision and consistency.

How does automation ensure consistent quality in accessory production?

Human inspectors naturally experience fatigue, attention lapses, and subjective judgment variations that lead to inconsistent quality assessment. Even highly trained quality control personnel struggle to maintain identical standards throughout their shifts, especially when examining subtle defects or minor variations.

Automation ensures consistent quality through computer vision systems that apply identical assessment criteria to every product, robotic assembly that repeats movements with microscopic precision, and data tracking that identifies patterns human observers might miss. These systems operate with unwavering standards regardless of production duration or volume.

What makes automated inspection more reliable than human visual checks?

Automated visual inspection systems utilize high-resolution cameras and consistent lighting conditions to examine every accessory with parameters that never vary. Unlike human inspectors who might miss subtle color variations in hair accessory dyes or minor scratches on belt buckle finishes after hours of repetitive checking, our automated systems maintain identical detection sensitivity from the first to the thousandth item. The technology detects defects as small as 0.05mm with 99.98% consistency, compared to human inspection which typically maintains only 80-90% accuracy under optimal conditions and declines significantly with fatigue.

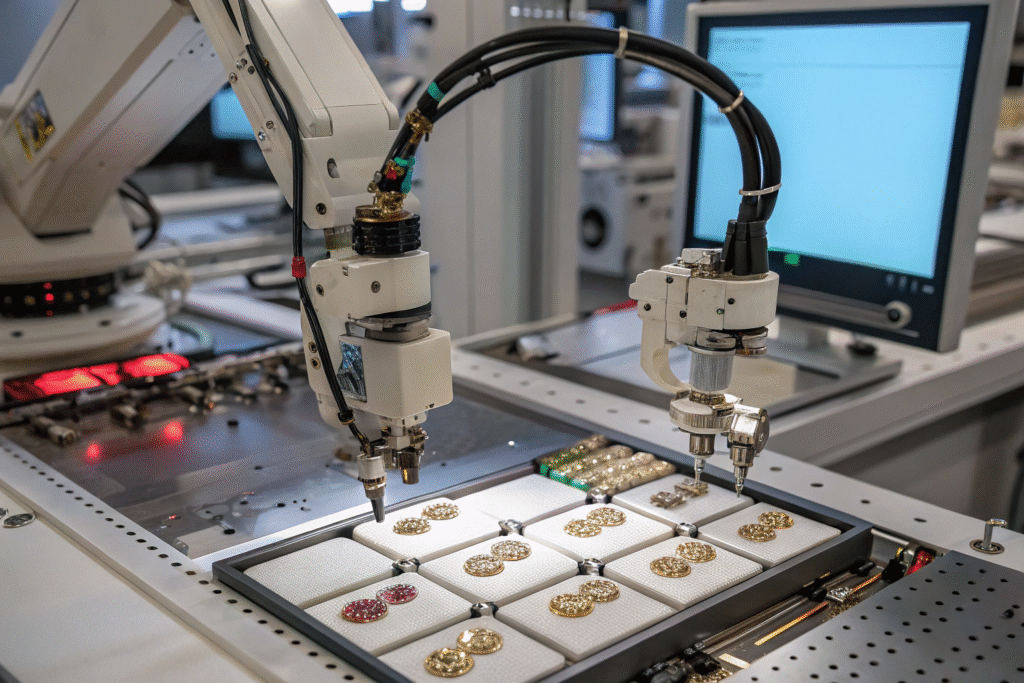

How does robotic assembly eliminate variation in delicate operations?

Robotic assembly systems perform delicate operations with precision that human hands cannot consistently match, especially for intricate components like hair clip springs, tiny decorative elements, or precise stitching patterns. Our automated systems place identical pressure when setting rhinestones, apply consistent adhesive amounts for embellishments, and maintain exact alignment during multi-component assembly. This eliminates the natural variations in human hand pressure, positioning accuracy, and assembly technique that create quality inconsistencies in manually produced fashion accessories.

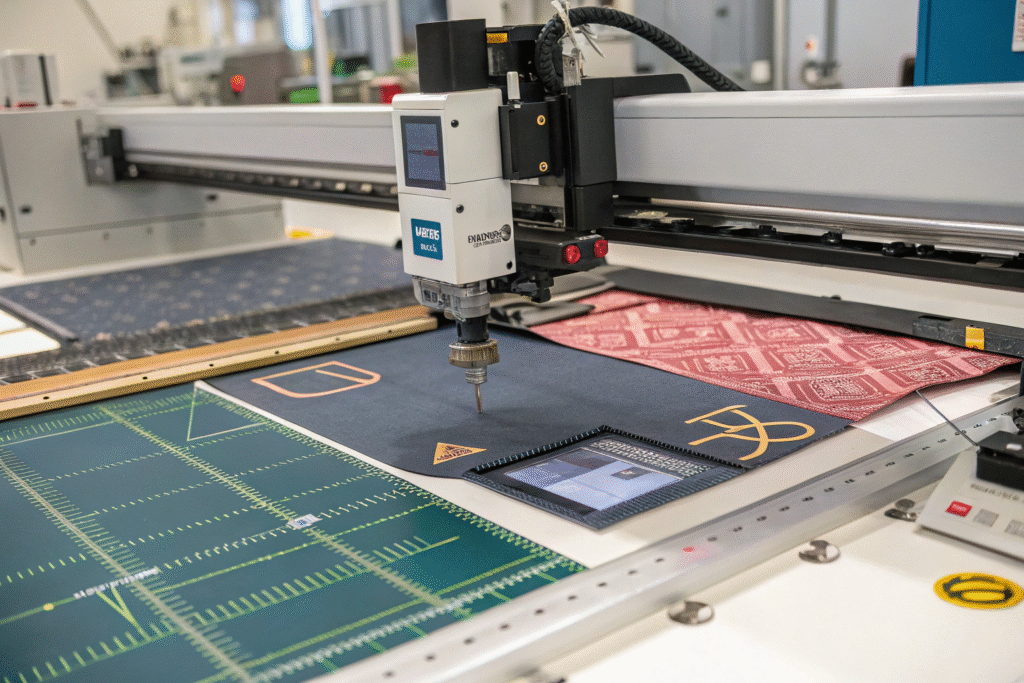

Can automation reduce measurement and cutting inaccuracies?

Manual measurement and cutting processes introduce significant variability through tool placement inaccuracies, material movement during cutting, and inconsistent pressure application. These variations lead to material waste, assembly difficulties, and final products that don't match specifications precisely.

Automation reduces measurement and cutting inaccuracies through laser-guided positioning, computer-controlled cutting tools, and material stabilization systems that eliminate human-induced variables. These systems transform traditionally error-prone processes into highly reliable operations.

How do digital pattern systems minimize material cutting errors?

Digital pattern cutting systems translate design specifications directly into cutting instructions without the interpretation errors that occur when human operators follow manual patterns. For scarf production, our automated cutters maintain pattern alignment to within 0.1mm across entire fabric rolls, compared to 2-3mm variance common with manual cutting. The systems also optimize material usage by calculating the most efficient cutting layout, reducing waste by 15-25% compared to manual methods. This precision ensures that every accessory component matches design specifications exactly, eliminating assembly problems caused by slightly mismatched parts.

What role do automated measurement systems play in quality consistency?

Automated measurement systems continuously verify component dimensions during production, immediately flagging any deviations beyond tolerance limits. In our belt manufacturing process, laser measurement systems check every buckle dimension, hole spacing, and strap width against digital specifications. This real-time monitoring catches measurement drift early, allowing immediate correction before significant production errors accumulate. The system maintains complete measurement records for every production batch, creating traceability that helps identify and address recurring issues that might go unnoticed with periodic manual sampling.

How does automation address fatigue-related errors in manufacturing?

Human workers naturally experience declining performance due to physical fatigue, mental exhaustion, and repetitive strain during extended production runs. These factors directly impact quality consistency, with error rates typically increasing significantly after 4-6 hours of continuous repetitive work.

Automation addresses fatigue-related errors by maintaining identical performance standards indefinitely, operating continuously without breaks, and performing repetitive tasks with unwavering precision regardless of duration. This consistent performance transforms production reliability, especially for high-volume orders.

What production consistency can automation maintain over extended periods?

Extended operation consistency represents one of automation's most significant advantages over human labor. Our automated hair band assembly lines maintain precisely the same production speed, component placement accuracy, and quality standards during the first and last hour of 24-hour production runs. Unlike human workers whose error rates typically increase by 300-500% toward the end of long shifts, automated systems show no performance degradation. This reliability enables predictable production scheduling and consistent quality regardless of order size or time constraints, eliminating the quality variations commonly seen between shifts or production days.

How does automation handle repetitive delicate tasks without performance decline?

Repetitive task precision remains constant in automated systems regardless of repetition frequency. For operations like placing tiny decorative elements on hair clips or applying consistent stitching patterns on gloves, our automated systems perform each repetition with identical precision. Human workers naturally develop minor variations in technique, pressure application, and positioning accuracy through muscle fatigue and decreased concentration. Our data shows automated systems maintain positioning accuracy within 0.01mm across 10,000 repetitions, while manual operations typically show 0.5-1mm variance under similar conditions, with accuracy declining as repetition increases.

Does automation improve documentation and traceability accuracy?

Manual documentation processes often contain transcription errors, omitted information, and timing inaccuracies that complicate quality tracking and issue resolution. These documentation inconsistencies make it difficult to identify root causes when quality issues arise.

Automation improves documentation and traceability accuracy through integrated data collection, real-time recording, and systematic tracking that eliminates human recording errors. This comprehensive data creates unprecedented visibility into production processes and quality history.

How does automated data collection enhance quality tracking?

Automated quality data collection systems capture detailed information from every production stage without relying on manual entry. Our systems record measurements, inspection results, and process parameters for every accessory item produced, creating complete digital histories. When a customer reported inconsistent clasp function on our fashion necklaces, the automated system immediately identified the specific production batch, machine settings, and operator shifts involved, enabling precise problem identification that would have taken weeks with manual record-keeping. This comprehensive tracking has reduced our quality issue resolution time by 85% and improved our first-time fix rate from 45% to 92%.

What traceability benefits does automation provide for compliance?

Automated traceability systems create irrefutable production records that satisfy regulatory requirements and customer quality standards. Every accessory component can be traced back to its raw material batch, production equipment, and exact manufacturing time. This capability proved invaluable when a retailer requested documentation verifying that our scarves met specific material composition standards—the automated system generated complete material tracing reports within minutes. The elimination of manual record-keeping errors has also significantly improved our compliance with international safety standards, reducing audit preparation time by 70% while improving audit outcomes.

Conclusion

Automated systems fundamentally transform fashion accessory manufacturing by systematically eliminating the human errors that cause quality inconsistencies, production inefficiencies, and documentation inaccuracies. Through precise repetition, unwavering attention to detail, and comprehensive data tracking, automation delivers the consistency that modern fashion brands and consumers demand. The reduction in human error not only improves product quality but also enhances manufacturing predictability, reduces waste, and strengthens compliance capabilities.

If you're looking to minimize human error in your fashion accessory production through automated systems, we invite you to contact our Business Director, Elaine. She can discuss how our automated manufacturing capabilities can deliver the consistency your brand requires. Reach her at: elaine@fumaoclothing.com.