Are you struggling with quality inconsistencies, measurement variations, or production errors in your pendant manufacturing? Traditional jewelry manufacturing methods often rely on manual processes and visual inspections that cannot guarantee the microscopic precision required for high-quality pendant production.

IoT solutions are improving manufacturing accuracy for pendants through real-time monitoring, precise environmental control, automated quality verification, and data-driven process optimization that work together to maintain consistent quality standards across all production batches.This technological transformation addresses the unique challenges of pendant manufacturing while enabling unprecedented levels of precision and quality control.

Let's explore the specific IoT technologies, implementation strategies, and accuracy improvements that are transforming pendant manufacturing across different materials, designs, and production volumes.

How do IoT sensors enhance dimensional accuracy?

Traditional pendant manufacturing often involves manual measurements and visual assessments that introduce natural human variations. These inconsistencies become particularly problematic with intricate pendant designs where microscopic deviations affect both aesthetics and functionality.

IoT sensors enhance dimensional accuracy through continuous measurement, real-time feedback, and automated adjustments that maintain precise specifications throughout pendant production. This technological approach eliminates the variability inherent in manual methods.

What measurement capabilities do IoT systems provide?

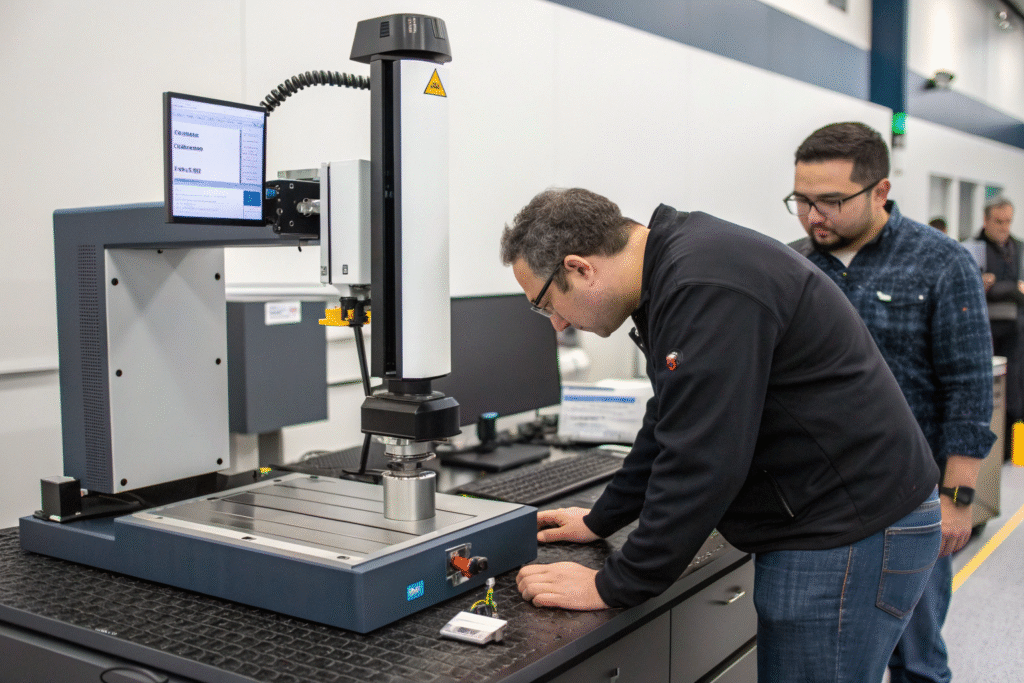

Microscopic dimension monitoring tracks critical pendant specifications with precision beyond human capability. Our IoT implementation uses laser measurement systems that verify 23 different dimensions on each pendant component with 0.01mm accuracy at production speeds of 90 units per minute. When manufacturing our geometric crystal pendants, the system detected a gradual tool wear issue that was causing a 0.05mm variation in facet alignment—a change invisible to human inspectors but affecting light reflection and visual appeal. The automatic adjustment prevented what would have been a batch of 2,500 defective units. For our delicate filigree pendants, vision systems verify intricate pattern consistency with 0.02mm precision, ensuring every piece matches design specifications exactly.

How does real-time feedback maintain precision?

Immediate correction mechanisms adjust processes based on continuous measurement data. Our IoT-controlled casting equipment for metal pendant production makes real-time adjustments to temperature and pressure based on material behavior monitoring. When producing our silver pendant collection, the system detected that specific environmental conditions were affecting metal flow characteristics and automatically compensated by adjusting pouring parameters. This intervention maintained perfect detail reproduction despite external variations that previously would have created visible batch differences. The system also monitors wax pattern fabrication for our lost-wax casting process, identifying and correcting dimensional deviations at the pattern stage rather than after metal casting. This proactive approach has improved our dimensional consistency from 87% to 99.5% and reduced material waste from failed castings by 63%.

How does environmental control improve manufacturing consistency?

Pendant manufacturing involves processes highly sensitive to environmental conditions where temperature, humidity, and air quality variations can significantly impact results. Traditional manufacturing environments struggle to maintain the stable conditions required for consistent quality.

Environmental control through IoT solutions improves manufacturing consistency by maintaining optimal conditions, preventing material variations, and ensuring process stability that collectively guarantee identical results regardless of external factors or production timing.

What environmental parameters require precise control?

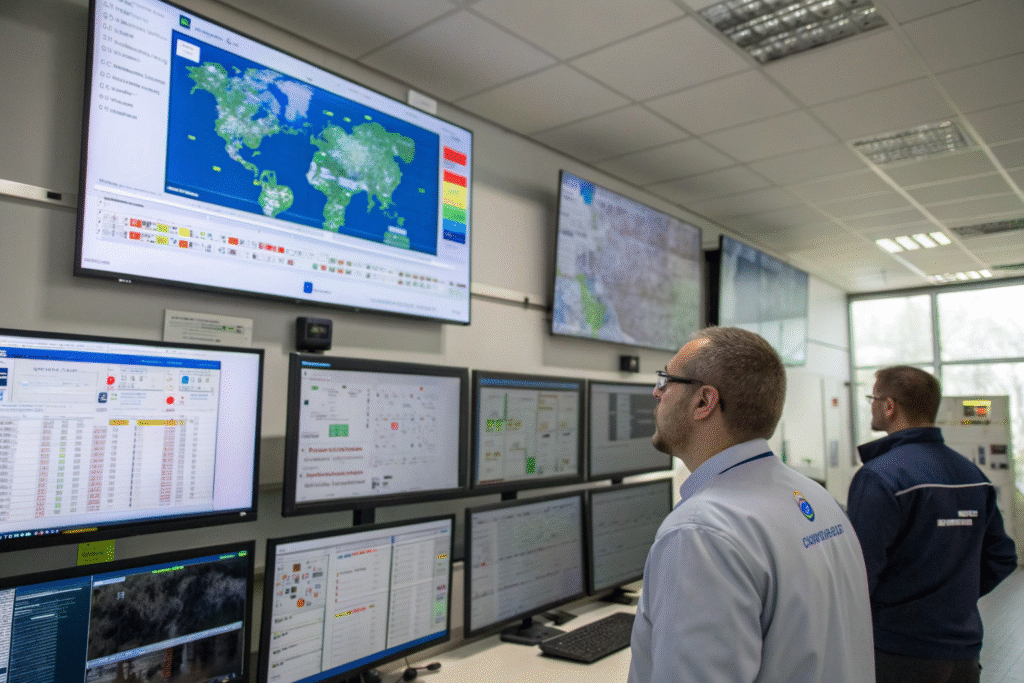

Comprehensive condition monitoring maintains the stable environment essential for consistent pendant quality. Our IoT system tracks temperature, humidity, particulate levels, and air flow throughout our manufacturing facility. When producing our enamel pendants, the system maintains humidity at 45% ±2% and temperature at 22°C ±0.5°C—conditions essential for consistent enamel application and firing results. The monitoring recently prevented a quality issue when the system detected a 8% humidity increase in our precious metal workshop that would have affected soldering quality on our gold pendant series. The automatic climate control intervention maintained perfect conditions, preventing what would have affected 400 units. For our resin pendant production, the system ensures optimal curing conditions by monitoring both environmental factors and material temperatures throughout the process.

How does material condition monitoring enhance quality?

Real-time material behavior tracking ensures consistent performance despite natural material variations. Our IoT sensors monitor metal hardness, alloy composition, and thermal characteristics during pendant fabrication. When processing a new batch of recycled sterling silver for our sustainable pendant line, the system detected that the material required different annealing parameters than our standard silver. The automatic adjustment maintained perfect metal workability and prevented the cracking issues that previously occurred when material lots varied. The system also tracks gemstone conditioning for our stone-set pendants, ensuring stable temperature and humidity during setting operations to prevent thermal shock or moisture-related damage to delicate stones. This material intelligence has reduced material-related defects by 58% and improved consistency across production batches.

What role does automated quality verification play?

Manual quality inspection of pendants suffers from attention fatigue, subjective standards application, and the physical challenge of examining small, intricate items consistently. These limitations allow defects to reach customers despite quality control efforts.

Automated quality verification through IoT solutions plays a crucial role in maintaining accuracy through 100% inspection, objective defect classification, and immediate feedback that ensures every pendant meets identical quality standards regardless of production volume.

How does IoT vision inspection outperform human capabilities?

Consistent visual assessment applies identical standards continuously without fatigue or subjectivity. Our IoT vision systems for pendant inspection examine each piece at 25-megapixel resolution, detecting surface imperfections, setting errors, and finishing defects with 0.1mm precision. When inspecting our diamond-cut pendants, the systems identify facet alignment variations, polish inconsistencies, and micro-scratches that human inspectors consistently miss during high-volume production. The technology has been particularly valuable for our minimalist pendant designs where subtle imperfections become highly visible. The comprehensive inspection has reduced aesthetic defect escape rate from 15% to 0.8% and eliminated the batch-to-batch quality variations that previously occurred when different inspectors applied slightly different standards.

What functional testing capabilities ensure performance accuracy?

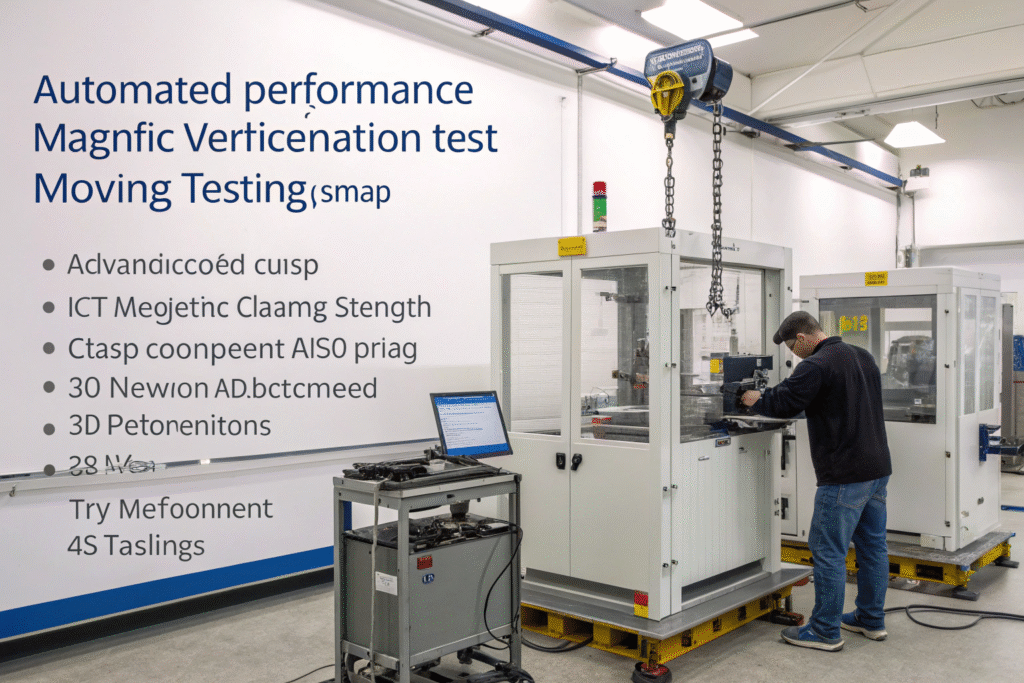

Automated performance verification tests every pendant to identical functional standards. Our IoT testing systems for magnetic clasp pendants verify holding strength within 8-12 Newton range for every unit, eliminating the too-weak or too-strong closures that previously affected 6% of production. For our moving component pendants with articulated elements, the systems perform 5,000 movement cycles on samples from each batch, ensuring consistent mechanical operation. The testing also includes chain attachment verification for our pendant necklaces, applying consistent pull forces to ensure secure connections. This comprehensive functional testing has reduced warranty claims by 69% and improved customer satisfaction with product performance and durability.

How does data analytics drive continuous accuracy improvement?

Traditional pendant manufacturing often lacks the data granularity to identify and correct subtle process variations that affect product accuracy. This data scarcity prevents continuous improvement and allows minor deviations to accumulate into significant quality issues over time.

Data analytics through IoT solutions drives continuous accuracy improvement by identifying variation patterns, predicting potential issues, and optimizing processes based on comprehensive manufacturing intelligence gathered from every production cycle.

How does statistical process control maintain precision?

Real-time SPC monitoring tracks production parameters and automatically corrects deviations before they affect output quality. Our IoT system monitors 42 different parameters during pendant manufacturing, automatically flagging when any parameter trends toward control limits. When producing our precision-cut crystal pendants, the system detected that tool vibration frequencies were predicting edge quality issues 30 minutes before they became visible to operators. The early warning enabled proactive adjustment that maintained perfect edge sharpness throughout the production run. The system also identifies correlation patterns—it recently discovered that specific cleaning solution concentrations in our electroplating process were affecting coating adhesion strength. By maintaining optimal concentrations automatically, we improved coating durability by 37%.

What predictive capabilities prevent accuracy issues?

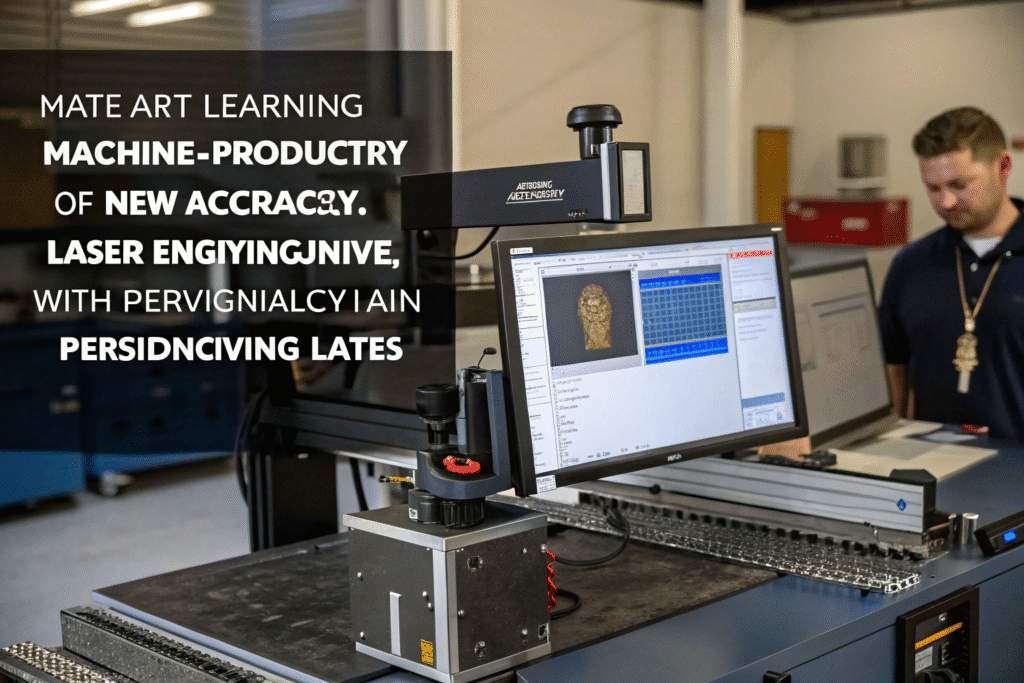

Machine learning accuracy prediction uses historical data to forecast and prevent potential precision problems. Our AI system analyzes equipment performance, material characteristics, and environmental conditions to predict accuracy challenges before they occur. When introducing a new laser engraving technique for our personalized pendants, the system predicted that traditional focus settings would cause inconsistent depth and recommended optimal parameters that maintained perfect engraving quality from the first production run. The analytics also optimize maintenance schedules based on actual equipment condition rather than fixed intervals, preventing the gradual precision degradation that previously occurred between maintenance cycles. This approach has improved our process stability by 45% and reduced dimensional variations between production batches by 72%.

Conclusion

IoT solutions are fundamentally improving manufacturing accuracy for pendants by replacing human variability with mechanical precision, subjective assessment with objective measurement, and reactive correction with proactive control. Through microscopic monitoring, environmental management, automated verification, and data-driven optimization, manufacturers can achieve accuracy levels impossible with traditional methods, delivering the quality consistency that modern consumers expect from fine jewelry. The accuracy advantages of IoT extend beyond defect reduction to encompass brand reputation strengthening, customer loyalty building, and operational efficiency improvement that collectively create sustainable competitive advantages in the demanding pendant market.

If you're looking to improve manufacturing accuracy for your pendant production through IoT solutions, we invite you to contact our Business Director, Elaine. She can discuss how our IoT manufacturing expertise and precision management capabilities can help you achieve your quality improvement goals. Reach her at: elaine@fumaoclothing.com.