Are you struggling with extended production cycles, sampling delays, or inability to quickly respond to trending hair accessory designs? Traditional hair clip manufacturing involves numerous manual processes, physical sampling, and sequential approvals that create significant delays between design conception and market availability.

Digital solutions are reducing time-to-production for hair clips by streamlining design processes, automating manufacturing preparations, enhancing collaboration, and optimizing production workflows through integrated digital technologies that replace time-consuming analog methods. This transformation enables manufacturers to respond to fast-changing fashion trends with unprecedented speed while maintaining quality and cost efficiency.

Let's explore the specific digital technologies and implementation strategies that are accelerating hair clip production timelines and how these solutions address traditional bottlenecks throughout the manufacturing process.

How do digital design tools accelerate hair clip development?

Traditional hair clip development involves multiple physical prototypes, manual specification creation, and sequential approval processes that typically require 3-6 weeks before production can begin. This extended development cycle prevents manufacturers from capitalizing on emerging trends with short lifecycles.

Digital design tools accelerate hair clip development through 3D modeling, virtual prototyping, simulation testing, and automated specification generation that compress development timelines from weeks to days while improving design accuracy and manufacturing feasibility.

What time savings come from virtual prototyping?

3D modeling and virtual sampling eliminate the need for multiple physical prototypes that traditionally slow down hair clip development. Our implementation of parametric 3D design software for decorative hair clips reduced sampling time from 21 days to just 3 days while allowing for more creative experimentation. Designers can now explore dozens of variations in hair clip mechanisms, decorative elements, and color combinations without the cost and delay of physical sampling. This acceleration proved crucial when a major retailer requested last-minute design modifications to our seasonal hair accessory collection—we delivered revised virtual prototypes within 24 hours, securing an order that would have been impossible with traditional methods. The reduction in physical sampling has also decreased development costs by 68% and material waste by 79%, creating both time and sustainability benefits.

How does simulation testing reduce development iterations?

Digital simulation and testing validate hair clip functionality and durability before physical production begins. Our finite element analysis software tests clip mechanism durability under repeated use conditions, identifying potential failure points during the design phase rather than after production. For spring-loaded hair clips, the simulation analyzes force distribution and material stress, ensuring comfortable operation without compromising holding power. When developing our new magnetic hair clip line, simulation identified that certain metal compositions would lose magnetic properties over time, enabling material adjustments before tooling commenced. This proactive approach has reduced design-related production issues by 84% and eliminated the typical 2-3 redesign cycles that previously added weeks to our development timeline.

What role does automation play in production preparation?

Traditional production preparation for hair clips involves manual tooling design, sample approval processes, and production planning that create significant delays between design finalization and manufacturing startup. These analog processes are particularly time-consuming for hair clips with complex mechanisms or decorative elements.

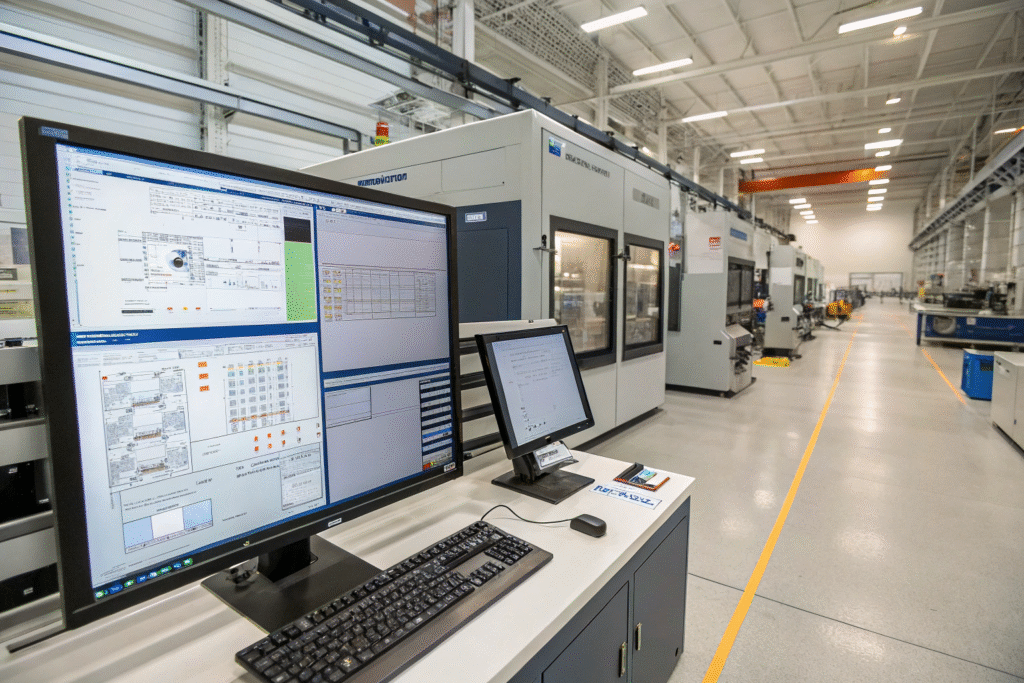

Automation accelerates production preparation through computer-aided manufacturing, digital tooling, automated nesting, and robotic programming that transform digital designs into production-ready instructions with minimal manual intervention. This seamless transition from design to manufacturing eliminates traditional bottlenecks.

How does digital tooling reduce setup time?

Computer-generated tooling designs automatically create production molds, dies, and fixtures from 3D design files. Our automated tooling system for injection-molded hair clips reduced mold design and fabrication time from 4 weeks to 10 days while improving accuracy. The system automatically identifies potential manufacturing issues like undercuts, thin walls, or ejection problems during the design phase, preventing costly tooling modifications later. For our metal hair clip components, the system generates CNC tool paths optimized for material usage and machining time. This automation has been particularly valuable for complex designs like our articulated hair claws with multiple moving parts, where manual tooling design previously required 6-8 weeks of intricate engineering work that now completes in 12 days with superior results.

What production planning efficiencies do digital systems enable?

Integrated digital planning systems synchronize all production preparation activities to minimize delays. Our manufacturing execution system automatically generates material requirements, production schedules, and quality control plans based on digital design data. When launching a new decorative hair pin collection, the system simultaneously orders materials, schedules equipment, and prepares quality documentation—processes that previously required sequential manual coordination taking 2-3 weeks now complete in 4 days. The system also optimizes production sequencing based on material availability and equipment capacity, preventing the typical 1-2 week delays that occurred when production planning discovered resource conflicts after designs were finalized. This integrated approach has reduced our average time from design approval to production start from 23 days to 7 days.

How do digital collaboration platforms accelerate decision-making?

Traditional hair clip development involves multiple stakeholders across design, engineering, marketing, and manufacturing who typically work sequentially with information passed through meetings, emails, and physical samples. This fragmented approach creates communication gaps, misinterpretations, and delayed decisions that extend timelines.

Digital collaboration platforms accelerate decision-making through real-time sharing, simultaneous review, version control, and automated approval workflows that enable all stakeholders to participate concurrently rather than sequentially. This parallel processing dramatically compresses decision cycles.

What efficiencies come from real-time design review?

Cloud-based collaboration tools enable instant feedback and decision-making regardless of participant locations. Our implementation allows designers in New York, engineers in Shanghai, and marketing teams in London to simultaneously review and annotate hair clip designs in virtual meeting spaces. When developing our recent collaborative hair accessory collection with an international fashion influencer, the digital platform reduced design review cycles from 3 weeks to 4 days by eliminating time zone delays and travel requirements. The system maintains complete version history and decision records, preventing the confusion that previously occurred when different departments worked with outdated design iterations. This collaborative approach has reduced design-related rework by 73% and decreased the average number of review cycles from 5.2 to 2.3 before final approval.

How do automated approval workflows accelerate progress?

Structured digital approval processes ensure timely decisions without manual follow-up. Our configured workflow automatically routes designs to appropriate stakeholders based on predefined rules and escalates overdue items without human intervention. For new hair clip developments, the system simultaneously seeks manufacturing feasibility approval, cost validation, and marketing alignment rather than sequentially. When a design modification affects multiple areas, the system identifies all impacted stakeholders and ensures coordinated review. This automation has eliminated the typical 5-8 day delays that occurred when approval requests sat unnoticed in inboxes or required manual tracking. The system also provides real-time visibility into approval status, enabling proactive management of potential bottlenecks before they impact timelines.

What production efficiencies do digital manufacturing systems provide?

Traditional hair clip manufacturing involves manual setup, analog quality checks, and disconnected processes that create inefficiencies and delays throughout production. These limitations become particularly problematic with complex hair clips requiring precise assembly of multiple components.

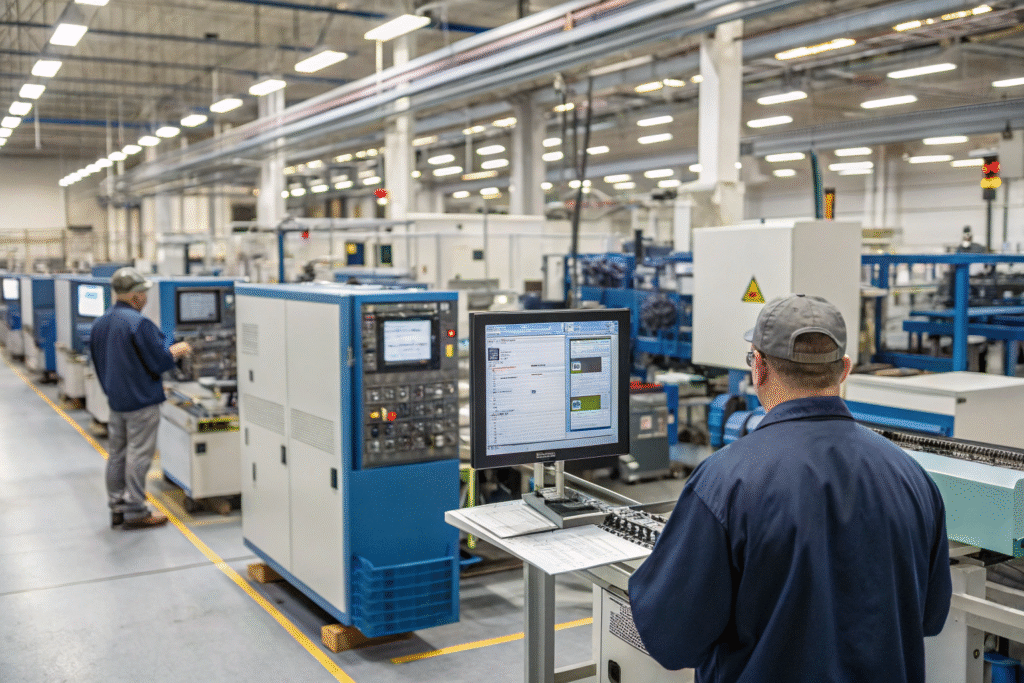

Digital manufacturing systems provide production efficiencies through automated setup, real-time monitoring, adaptive control, and integrated quality assurance that optimize the entire manufacturing process from raw material to finished product. This comprehensive digital integration minimizes non-value-added time throughout production.

How does automated setup reduce changeover time?

Computer-controlled equipment configuration enables rapid transitions between different hair clip styles with minimal manual intervention. Our automated production lines for plastic hair clips can change between 12 different designs in under 15 minutes compared to the 2-4 hours required with manual setup. The system automatically adjusts injection molding parameters, assembly robot programs, and decoration equipment settings based on digital product records. This flexibility has been particularly valuable for our custom hair clip service, where we frequently produce small batches of personalized designs. The ability to quickly switch between custom orders has reduced our minimum economical batch size from 5,000 units to 500 units, enabling profitable production of specialized designs that previously weren't feasible.

What production acceleration comes from real-time monitoring?

Continuous performance optimization uses real-time data to identify and address inefficiencies as they occur. Our IoT-enabled production equipment monitors cycle times, quality metrics, and resource consumption, automatically making micro-adjustments to maintain optimal performance. When producing our metal hair clip series, the system detected that ambient temperature variations were affecting spring coiling consistency and automatically compensated by adjusting coiling tension. This real-time adaptation prevented the production of 1,200 defective units that would have required rework, saving 16 production hours. The system also identifies emerging maintenance needs before they cause downtime, predicting tool wear with 92% accuracy based on performance patterns. This proactive approach has increased our overall equipment effectiveness from 74% to 91% and reduced unplanned downtime by 83%.

Conclusion

Digital solutions are fundamentally transforming hair clip manufacturing by replacing time-consuming analog processes with integrated digital workflows that accelerate every stage from design to delivery. Through virtual prototyping, automated preparation, collaborative platforms, and smart manufacturing, manufacturers can dramatically reduce time-to-production while improving quality, flexibility, and cost efficiency. As hair accessory trends continue to evolve with increasing speed, the ability to quickly translate designs into market-ready products becomes increasingly crucial for competitive success. Manufacturers who embrace comprehensive digital transformation position themselves to lead in the fast-paced fashion accessories market.

If you're looking to reduce time-to-production for your hair clip collections through digital solutions, we invite you to contact our Business Director, Elaine. She can discuss how our digital manufacturing capabilities and implementation experience can help you achieve faster time-to-market. Reach her at: elaine@fumaoclothing.com.