For any fashion brand or retailer, translating a stunning, intricate design onto a scarf can be a major production challenge. Traditional printing methods often impose frustrating limitations on creativity, color, and detail. As a manufacturer who has worked with countless designers, I've seen how digital printing has revolutionized this product category. It directly answers the demand for high-quality, fast-development, and highly customizable fashion accessories.

Digital printing is the ideal solution for complex scarf designs because it eliminates the technical and cost barriers of traditional methods, enabling unlimited colors, photorealistic detail, and cost-effective small-batch production. This technology allows designers to treat silk, chiffon, or wool like a blank canvas, perfectly reproducing everything from delicate watercolor florals to intricate geometric patterns without compromise. It aligns perfectly with the needs of brands that require speed to market and design flexibility.

The shift towards digital is more than a trend; it's a fundamental change in how scarves are conceived and produced. Let's explore the specific advantages that make digital printing the superior choice for bringing complex designs to life.

How Does Digital Printing Achieve Unlimited Color and Detail?

The most immediate advantage of digital printing is its ability to reproduce virtually any design imaginable. Unlike traditional methods, it is not constrained by the physics of screens or rollers.

Digital printing works like a sophisticated inkjet printer for fabric. The design is sent directly from a computer to the printer, which applies micro-droplets of ink onto the textile. This process allows for the use of an extensive color palette (often millions of colors) without the need for separate color separations or screens. It can achieve smooth gradients, subtle shadows, and incredibly fine lines that would be impossible, or prohibitively expensive, to produce with screen printing. This capability is perfect for designs that mimic watercolor paintings, detailed photography, or complex digital art.

What Are the Technical Limitations of Traditional Methods?

To appreciate digital, one must understand the constraints of analog. Screen printing, while excellent for bold, simple designs, requires a separate screen for each color. A design with 20 colors needs 20 screens, driving up setup costs and time. It also struggles with color blending and fine detail. Rotary printing has similar limitations and typically requires massive minimum order quantities (MOQs) to justify the high setup cost of engraving printing rollers. These methods create a significant barrier for complex, colorful designs, making them economically viable only for very large, standardized runs. For brands looking to offer uniqueness and trend-responsive designs, these traditional paths are often closed. Resources from the Digital Textile Community often discuss these technical comparisons in depth.

How Does This Directly Benefit Brands and Designers?

This technical freedom translates into direct business benefits. Designers are no longer forced to simplify their visions. They can create intricate patterns that become a brand's signature, knowing production will not dilute their artwork. It enables true fast fashion and just-in-time production, as there are no lengthy setup processes. Brands can test market reception with a small batch of a complex design before committing to a large order, significantly reducing financial risk. This agility is a cornerstone of modern fashion business models. For manufacturers like us at Shanghai Fumao Clothing, investing in state-of-the-art digital printing technology is an investment in our clients' creative and commercial freedom.

Why is Digital Printing Perfect for Small Batches and Customization?

The fashion industry is moving towards greater personalization and reduced inventory risk. Digital printing is inherently suited to this shift, as its economics are decoupled from scale.

The core reason is the near-zero setup cost. Whether you print one scarf or one thousand, the process is essentially the same: send the digital file and load the fabric. This makes it immensely cost-effective for low MOQs (Minimum Order Quantities). Brands can produce limited editions, create customized scarves for specific events or clients, or offer a vast array of designs without being burdened by excessive stock. It enables a "print-on-demand" model that aligns with today's demand for unique, personalized products.

How Does This Reduce Risk and Increase Responsiveness?

For buyers and brands, this flexibility is transformative. Consider these scenarios:

-

Market Testing: Launch 10 different complex designs in small quantities to see which resonates best with customers before scaling up.

-

Seasonal Agility: Introduce new designs mid-season to capture emerging trends without committing to huge inventory.

-

Personalization: Offer monogramming or custom color variations for special collections or corporate gifting.

This model drastically reduces the capital tied up in unsold inventory and minimizes waste, contributing to more sustainable business practices. It turns the traditional, forecast-heavy supply chain into a responsive, demand-driven one. Industry analyses on platforms like Just-Style frequently highlight the supply chain advantages of digital textile printing.

What Does This Mean for Lead Times and Development Speed?

The impact on speed is profound. The traditional cycle of creating screens/rollers, approving color separations, and setting up the print line can take weeks. Digital printing compresses this to days. From final design approval, you can move to a production sample and then to bulk production with incredible speed. This fast development and production cycle is a critical competitive advantage, allowing brands to react in near-real-time to social media trends or cultural moments. For a professional buyer like Ron, who values timeliness, this means getting innovative products to market faster and capitalizing on shorter selling windows.

What Are the Advantages in Fabric and Sustainability?

Digital printing isn't just about design; it also offers tangible benefits in terms of material handling and environmental impact, which are increasingly important to consumers and brands.

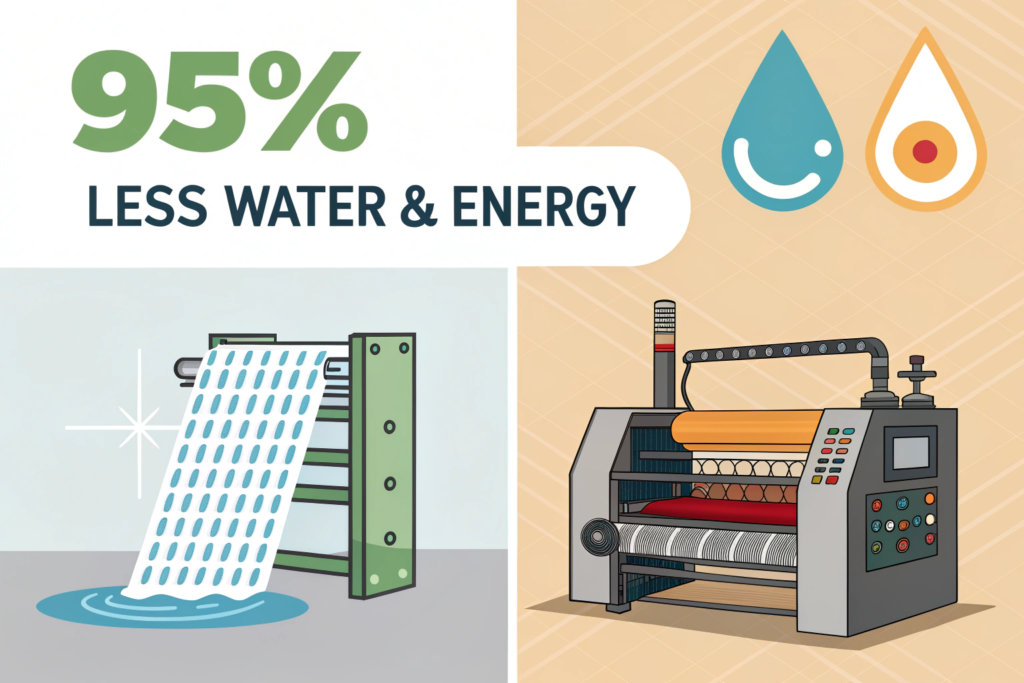

The process is generally more fabric-friendly. It uses less water and energy compared to traditional wet printing processes. The inks are often applied more precisely, resulting in less waste runoff. Many digital printers now use eco-friendly, water-based pigments or reactive dyes, which have a lower environmental footprint. Furthermore, because it requires no physical screens or rollers, there is no waste associated with creating and disposing of these tools for each design.

How is Digital Printing Applied to Different Scarf Fabrics?

A key strength is its versatility across materials. High-quality digital printers can be calibrated for a wide range of natural and synthetic fabrics essential for scarves:

-

Silk & Chiffon: Achieves breathtaking, vibrant results without compromising the delicate drape of the fabric.

-

Wool & Cashmere: Can print on knitted or woven wool fabrics, allowing for complex patterns on winter accessories.

-

Polyester & Blends: Works excellently with disperse dyes, resulting in bright, durable prints.

This versatility means a brand can use the same intricate design across a capsule collection featuring different scarf materials, ensuring consistency. The technology allows for precise ink penetration, resulting in prints that are colorfast and durable to washing, maintaining the high quality of the accessory. Organizations like the Sustainable Apparel Coalition provide frameworks that highlight the benefits of such efficient production methods.

Does This Align with Modern Consumer and Brand Values?

Absolutely. The ability to produce closer to demand reduces overproduction, a major issue in the fashion industry. The reduced water and chemical usage is a powerful story for brands marketing to environmentally conscious consumers. When you combine this with the creative possibilities, digital printing offers a compelling value proposition: beautiful, unique products created responsibly. For a manufacturer, promoting these capabilities is not just about technology specs; it's about partnering with brands to meet their ethical and aesthetic goals. This holistic service is what defines a modern, reliable partner like Shanghai Fumao Clothing.

How to Ensure Quality When Choosing a Digital Print Partner?

While the technology is powerful, the outcome depends entirely on the manufacturer's expertise. Not all digital printing is created equal. The choice of partner determines the final quality, consistency, and reliability of your beautifully designed scarves.

High-quality digital printing is a combination of premium hardware, expert technicians, and rigorous quality control. It starts with fabric pre-treatment and ends with precise steam fixation and washing. A professional factory will have a controlled environment for printing and a dedicated QC team that checks for color accuracy, print alignment, and any defects across the entire batch. They should provide detailed lab dip and strike-off samples for approval before bulk production, ensuring the digital file translates perfectly to the chosen fabric.

What Technical Specifications Should You Inquire About?

When vetting a manufacturer, go beyond asking "Do you do digital printing?" Ask specific questions to gauge their proficiency:

| Key Evaluation Factor | Questions to Ask Your Manufacturer |

|---|---|

| Printing Technology | What type of digital printers do you use (e.g., Kornit, MS, Epson)? What ink systems (reactive, pigment, acid)? |

| Color Management | How do you ensure color accuracy from screen to fabric? Do you use ICC profiles for different fabrics? |

| Fabric Handling | What is your process for fabric pre-treatment and post-print fixation? |

| Quality Assurance | What is your QC protocol for digital prints? What is your acceptable defect rate? |

Why is the Manufacturer's Role Critical in the Creative Process?

An experienced manufacturer acts as a technical consultant. They can advise on the best fabric base for your desired design effect (e.g., silk satin for vibrancy vs. crêpe de Chine for a matte, painterly look). They can review your design files and suggest optimal resolutions, color modes (CMYK vs. RGB), and repeat sizes for different scarf dimensions. This guidance prevents costly errors and ensures the final product matches your vision. Their expertise in logistics also ensures the delicate printed scarves are properly packaged and shipped to avoid damage. For authoritative information on textile testing standards, which underpin good QC, resources from Intertek or SGS are essential references. Choosing a partner with this depth of knowledge turns a complex production process into a smooth, reliable experience.

Conclusion

Digital printing has fundamentally changed the game for complex scarf designs. It removes the traditional barriers of color count, detail, and scale, unlocking unparalleled creative freedom. For brands and retailers, this translates into the ability to offer unique, high-quality products with faster speed to market, lower financial risk through small-batch production, and a more sustainable manufacturing footprint.

The combination of artistic possibility and commercial agility makes digital printing not just an ideal choice, but often the only viable choice for today's intricate and trend-driven scarf designs. It is a technology that perfectly serves the modern demand for customization, speed, and responsibility.

If you are looking to bring stunning, complex scarf designs to life with a partner that masters both the art and science of digital printing, we are here to help. At AceAccessory, our design and production teams specialize in translating intricate concepts into beautiful, market-ready accessories. To discuss your next scarf collection, please contact our Business Director Elaine at elaine\@aceaccessory.com.