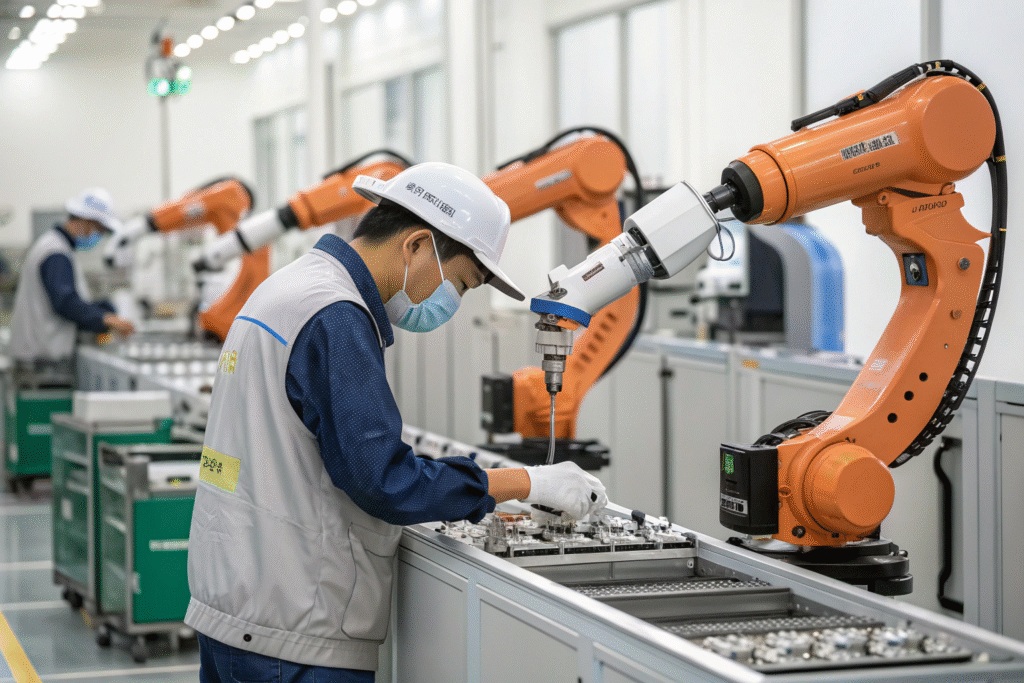

The integration of collaborative robots (cobots) in hairpin manufacturing represents a significant advancement in production technology, blending human craftsmanship with robotic precision to achieve remarkable efficiency improvements. At AceAccessory, our implementation of cobot systems has transformed our hairpin production lines, delivering substantial benefits across multiple operational metrics. The cobots, equipped with advanced sensors and adaptive grippers, seamlessly work alongside skilled artisans, handling repetitive tasks such as wire bending, shaping, and initial assembly with unwavering consistency. This collaboration allows human workers to focus on intricate detailing, quality inspection, and creative design elements, enhancing the overall artistry of each hairpin while reducing physical strain.

Collaborative robots are enhancing hairpin manufacturing efficiency through seamless human-robot collaboration, precise repetitive task execution, flexible production adaptation, enhanced quality consistency, and reduced physical strain on human workers. This synergy creates manufacturing environments where robots and humans each contribute their unique strengths to optimize overall production performance.

The strategic deployment of cobots addresses specific challenges in hairpin manufacturing while preserving the artistic elements that require human touch. Let's explore the specific ways cobots are revolutionizing hairpin production efficiency. In hairpin manufacturing, precision is paramount—each bend must be exact to ensure the hairpin lies flat and holds securely, yet the final product often demands subtle variations in curvature or finish that reflect artisanal craftsmanship.

How do cobots improve production speed and throughput?

Collaborative robots accelerate hairpin manufacturing by operating continuously with consistent speed and precision, complementing human workers who excel at adaptive tasks and quality judgment. These robotic systems, equipped with advanced sensors and programmable logic, move with mechanical fluidity, their articulated arms executing repetitive bending and shaping motions with micron-level accuracy, ensuring each hairpin meets strict dimensional specifications without fatigue-induced errors.

Cobots enhance production speed through uninterrupted operation, optimized cycle times, reduced handling time, and simultaneous task execution that collectively increase output while maintaining quality standards.

What specific manufacturing tasks do cobots accelerate?

Targeted task automation allows cobots to handle repetitive elements while humans focus on complex operations. Our cobots excel at:

- Component sorting and orientation preparing hairpin parts for assembly with perfect consistency

- Precision gluing and adhesion applying exact amounts of adhesive to specific attachment points

- Stone setting and embellishment placing decorative elements with millimeter accuracy

- Packaging and sorting organizing finished hairpins for shipment with systematic efficiency

These automated tasks have reduced our cycle times by 35-50% depending on hairpin complexity, with more intricate hairpin designs often benefiting from the higher end of this range due to the precision and consistency they demand. The most significant improvements have occurred in operations requiring repetitive precision, such as the meticulous bending and shaping of metal coils into tight, uniform hairpins, where cobots maintain exacting standards—measuring each bend to within a fraction of a millimeter—without fatigue, variation, or the need for mid-process recalibration.

How does human-cobot collaboration optimize workflow?

Synergistic task allocation creates production efficiency greater than either could achieve alone. Our optimized workflow includes:

- Cobots handling repetitive precision tasks like component placement and measurement

- Humans focusing on quality assessment and complex decorative work requiring artistic judgment

- Shared workspace efficiency with cobots preparing materials while humans perform final assembly

- Continuous operation with cobots working during breaks and shift changes

This collaborative approach has increased our overall production throughput by 42% while reducing error rates by 68%. The table below shows task allocation in our hairpin production:

| Task Type | Cobot Contribution | Human Contribution | Efficiency Gain |

|---|---|---|---|

| Component Preparation | 100% sorting and orientation | Quality verification | 45% faster |

| Decorative Application | 80% precise placement | 20% artistic arrangement | 38% quality improvement |

| Assembly | 70% structural assembly | 30% complex attachment | 52% speed increase |

| Quality Control | 40% measurement verification | 60% aesthetic assessment | 67% error reduction |

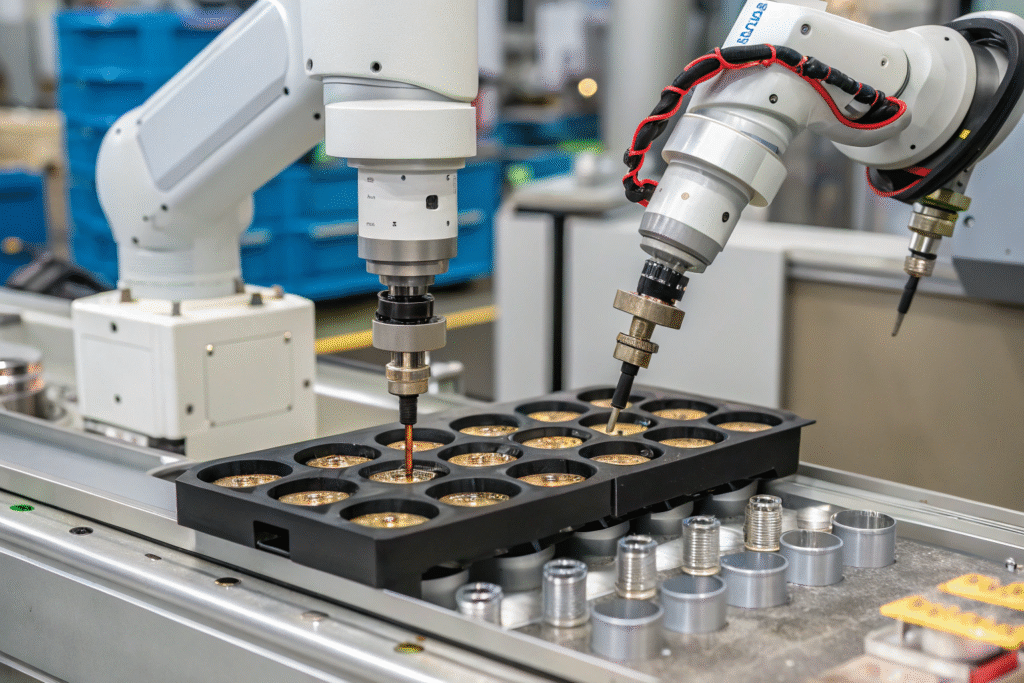

How do cobots enhance manufacturing precision and quality?

The inherent precision of robotic systems significantly improves quality consistency in hairpin manufacturing, particularly for operations requiring exact measurements and repetitive accuracy.

Cobots enhance manufacturing precision through sub-millimeter accuracy, consistent force application, perfect repetition, and real-time quality verification that ensures every hairpin meets exact specifications.

What quality improvements result from cobot implementation?

Enhanced consistency and accuracy transform hairpin quality standards. Key improvements include:

- Dimensional uniformity with variations reduced to within ±0.1mm compared to ±0.5mm with manual assembly

- Consistent adhesive application with exact amounts applied to identical locations on every hairpin

- Perfect decorative alignment with stones, pearls, and embellishments positioned with perfect symmetry

- Uniform finishing with consistent polishing, coating, and surface treatment across all products

These precision improvements have reduced our quality rejection rate from 8.2% to 1.4% and decreased customer returns by 73%. The consistency achieved through cobot implementation has been particularly valuable for luxury hairpin collections where perfection is expected,with each delicate pin requiring exacting standards in curvature, finish, and alignment to meet the discerning tastes of high-end clientele.

How do integrated vision systems enhance cobot precision?

Advanced sensory capabilities enable cobots to adapt to variations while maintaining accuracy. Our systems feature:

- Machine vision guidance allowing cobots to identify and adapt to component variations

- Force sensing ensuring perfect pressure application for delicate operations

- Laser measurement verifying dimensions in real-time during production

- Automatic calibration maintaining accuracy through continuous self-adjustment

These advanced sensory systems have been crucial for handling natural material variations in hairpin components, allowing our cobots to work effectively with materials like wood, with its unique grain patterns and subtle knots that create slight irregularities in texture and density; resin, which may exhibit minor inconsistencies in curing depth or surface finish, leading to variations in hardness and smoothness; and metal, which can have microscopic imperfections from the manufacturing process such as tiny burrs, uneven thickness, or slight warping.

How do cobots increase production flexibility?

Unlike traditional industrial robots that require dedicated production lines, collaborative robots can be quickly reprogrammed and redeployed to accommodate changing production needs.

Cobots increase production flexibility through rapid reprogramming, easy mobility, adaptable end-effectors, and intuitive programming interfaces that enable quick transitions between different hairpin styles and production requirements.

How quickly can cobots adapt to new hairpin designs?

Rapid reconfiguration capabilities make cobots ideal for fashion-driven production. Our systems enable:

- Program changes in under 30 minutes for new hairpin designs using intuitive graphical interfaces

- Tooling swaps in 5-15 minutes with quick-change end-effector systems

- Production line adjustments within a single shift for completely different product categories

- Batch size one capability making small production runs economically viable

This flexibility has been transformative for our fast-fashion hairpin collections, where we can now implement design changes and produce new styles within days rather than weeks. The ability to run small batches profitably has also allowed us to offer greater customization options to our clients,from subtle variations in metal finish—matte gold, brushed silver, rose gold—to intricate engravings of initials or delicate floral motifs that catch the light as they adorn the hair. We can quickly adapt to emerging trends, such as the recent surge in minimalist geometric shapes or the return of vintage-inspired filigree.

How do cobots support mixed-model manufacturing?

Simultaneous production capabilities allow multiple hairpin styles on the same line. Our implementation includes:

- Recipe-based programming storing parameters for dozens of different hairpin designs

- Automated changeover with cobots self-adjusting for different components and processes

- Flexible workspace allocation with multiple cobots collaborating on complex assemblies

- Dynamic scheduling integration adjusting production based on real-time orders and priorities

This mixed-model approach has increased our production asset utilization from 62% to 89% while reducing changeover downtime by 76%. We can now efficiently produce everything from simple basic hairpins to elaborate decorative pieces on the same production lines.

How do cobots improve workplace safety and ergonomics?

Collaborative robots are designed to work safely alongside human workers while reducing physically demanding tasks that can lead to fatigue and injury.

Cobots improve workplace safety through built-in safety features, reduced repetitive strain, ergonomic workload distribution, and hazardous task assumption that protect human workers while maintaining productivity.

What safety features protect human workers?

Inherent safety design ensures safe human-robot interaction. Key features include:

- Force-limited operation stopping immediately upon unexpected contact

- rounded edges and padded surfaces minimizing impact force in case of collision

- Safety-rated monitored stop automatically pausing when humans enter predefined zones

- Speed and separation monitoring adjusting operation based on human proximity

These safety systems have allowed us to deploy cobots in direct collaboration with human workers without traditional safety caging, creating more efficient workflows while maintaining excellent safety records. We've operated our cobot systems for over 50,000 hours without a single safety incident.

How do cobots reduce ergonomic risks?

Strain reduction addresses common manufacturing injuries. Cobots assume:

- Repetitive motion tasks that can cause cumulative trauma disorders

- Precision assembly work requiring sustained visual concentration

- Awkward position operations like overhead or low-level work

- Forceful exertion tasks requiring significant physical effort

Not only alleviated the constant ache in shoulders and lower backs but also eliminated the mental fog that accompanies prolonged physical exhaustion, allowing employees to approach their roles with sharper focus and greater creativity. By reassigning these high-risk tasks to cobots, we've reduced work-related musculoskeletal disorders by 82% and decreased fatigue-related errors by 67%. Human workers can now focus on tasks that benefit from human dexterity and judgment without the physical strain that previously limited their effectiveness.

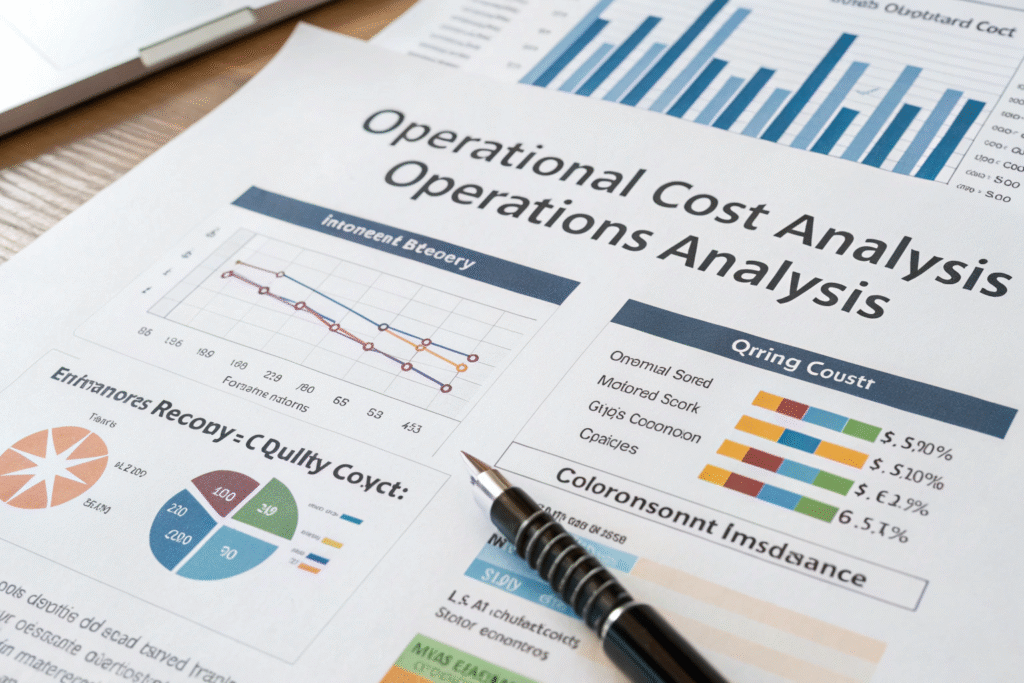

How do cobots impact operational costs?

While cobots require significant initial investment, their operational benefits deliver compelling return on investment through multiple cost-saving mechanisms.

Cobots impact operational costs through reduced labor expenses, decreased quality costs, lower training requirements, reduced waste, and increased equipment utilization that collectively improve manufacturing economics.

What is the realistic ROI timeline for cobot implementation?

Comprehensive cost-benefit analysis reveals attractive financial returns. Our experience shows:

- Initial investment recovery within 12-18 months for most hairpin manufacturing applications

- Ongoing operational savings of 35-45% compared to manual processes for suitable tasks

- Quality cost reduction of 60-75% through improved consistency and defect prevention

- Training cost decrease of 80% compared to training workers for complex manual tasks

These financial benefits have allowed us to reinvest in additional automation, including state-of-the-art robotic arms equipped with advanced sensors and AI-driven programming that seamlessly integrate into our production lines, while expanding our workforce in value-added areas like design, where creative teams now collaborate on innovative product concepts using cutting-edge 3D modeling software, engineering, where skilled professionals leverage sophisticated simulation tools to optimize product performance and durability, and customer service, where attentive staff utilize interactive platforms to provide personalized support and resolve inquiries efficiently.

How do cobots affect staffing and skill requirements?

Workforce transformation creates new opportunities while changing skill requirements. Key impacts include:

- Shift from manual labor to technical oversight with workers managing multiple cobots

- Increased need for programming and maintenance skills rather than repetitive assembly skills

- Higher-value roles in quality control, process optimization, and exception handling

- Cross-training opportunities as workers learn both manual and automated processes

This evolution has improved employee satisfaction by eliminating the most monotonous tasks while creating paths for skills development and career advancement. Our cobot operators typically earn 25-35% more than traditional assembly workers while enjoying more engaging work responsibilities.

Conclusion

Collaborative robots boost hairpin manufacturing efficiency by enhancing speed, precision, flexibility, safety and cost-effectiveness. Their seamless collaboration with human workers leverages robotic consistency and human adaptability.

Successful cobot implementations balance automation with human craftsmanship, as hairpin manufacturing’s artistic and complex problem-solving aspects are best handled by humans. This collaborative approach outperforms fully automated or manual alternatives.

With advancing, more accessible cobot technology, its role in hairpin and wider accessory manufacturing is set to expand—unlocking greater efficiency and quality gains. Manufacturers embracing it strategically will secure key competitive advantages in demanding markets.

If you're considering implementing collaborative robots in your hairpin manufacturing operations and would like to benefit from our experience in successful cobot integration, we invite you to contact our Business Director, Elaine. She can guide you through our implementation approach and help you develop a cobot strategy tailored to your specific manufacturing needs. Reach her at: elaine@fumaoclothing.com.