The hair accessory industry faces increasing pressure to deliver faster turnaround times while maintaining quality and managing costs. Traditional manufacturing methods, heavily reliant on manual labor and sequential processes, struggle to meet these competing demands. Through our implementation of automated systems across our hair accessory production lines, we've documented remarkable speed improvements that explain why automation has become essential for competitive manufacturing.

Automated systems are enhancing hair accessory production speed by eliminating manual handling time, enabling parallel processing, reducing error correction cycles, and optimizing material flow through integrated digital workflows.This technological transformation addresses the fundamental time constraints that limit traditional manufacturing while improving consistency and quality.

The speed advantages of automation extend beyond simple faster machinery to fundamentally reengineered production ecosystems. Let's examine the specific mechanisms through which automated systems accelerate hair accessory manufacturing.

How do automated assembly systems reduce production time?

Manual assembly of hair accessories involves numerous repetitive tasks that consume significant time while introducing natural variations in speed and quality. Automated assembly systems transform these sequential manual operations into synchronized, high-speed processes.

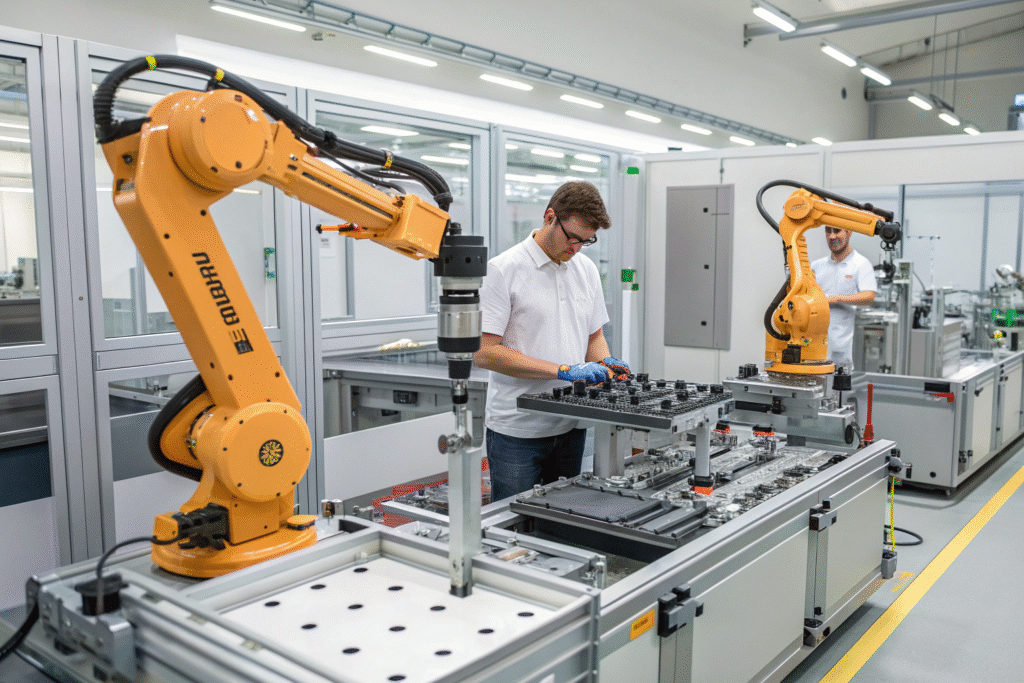

Robotic systems bring consistent speed and precision to operations that traditionally limited production throughput due to their labor-intensive nature.

What robotic positioning systems accelerate component placement?

Manual placement of decorative elements, clasps, and joining components represents a major time bottleneck in traditional hair accessory production. Our high-speed robotic positioning systems place components with precision measured in milliseconds, achieving speeds 5-7 times faster than manual methods. These systems use computer vision guidance to identify optimal placement locations and orientations, eliminating the measurement and marking time required in manual processes. For complex hair accessories with multiple attachment points, the systems execute synchronized multi-arm operations that place several components simultaneously rather than sequentially. This parallel processing approach has reduced assembly time for elaborate hair clips by up to 80% compared to traditional hand assembly methods.

How does automated fastening accelerate joining operations?

Manual sewing, gluing, and mechanical fastening operations naturally vary in speed and consistency. Our automated fastening systems complete joining operations with consistent speed regardless of complexity or duration. Ultrasonic welding systems create permanent bonds in 2-3 seconds compared to 30-45 seconds for manual gluing and clamping. Automated sewing machines maintain perfect stitch consistency at speeds up to 8,000 stitches per minute, far exceeding manual capabilities. For mechanical fasteners like snap closures and spring mechanisms, specialized automation places and secures components in single operations that previously required multiple manual steps. This fastening acceleration has dramatically reduced the time required to transform components into finished hair accessories.

How does automated material handling reduce non-value-added time?

Traditional hair accessory manufacturing involves significant time spent moving materials between workstations, organizing components, and managing work-in-process inventory. These non-value-added activities often consume 25-40% of total production time without contributing to the final product.

Automated material handling systems transform logistics from time-consuming manual activities to seamless, integrated processes that maintain continuous production flow.

What conveyor and sorting systems optimize workflow?

Manual material movement between production stages creates natural bottlenecks and waiting time. Our integrated conveyor systems automatically transfer components and partially completed hair accessories between workstations without human intervention. These systems include automated sorting capabilities that route items to the appropriate next station based on product type, customization requirements, or process sequence. For facilities producing multiple hair accessory styles simultaneously, the systems maintain perfect material synchronization that ensures each workstation receives the correct components precisely when needed. This automated flow has eliminated the material handling time that previously required dedicated personnel while preventing the production delays caused by material shortages or misrouting at manual transfer points.

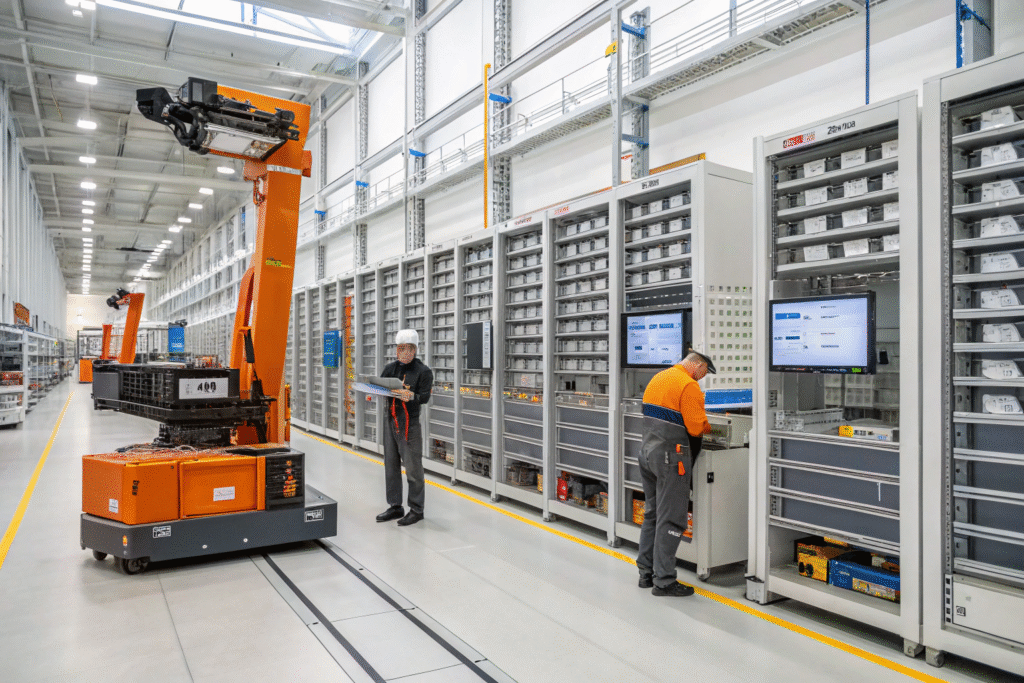

How do automated storage systems accelerate material access?

Traditional component storage and retrieval consumes significant production time as workers search for, count, and transport materials. Our automated storage and retrieval systems (AS/RS) organize components in high-density storage that robots can access within seconds. The systems maintain real-time inventory tracking that automatically triggers replenishment orders when supplies run low. For production scheduling, the systems provide instant component availability information that enables more accurate planning and prevents delays from material shortages. This automated approach has reduced material access time by 75% while eliminating the production interruptions previously caused by manual inventory management and component searching.

How do integrated digital systems accelerate process coordination?

Traditional manufacturing suffers from communication delays between design, planning, production, and quality control departments. Digital integration creates seamless information flow that eliminates the coordination time lags that slow traditional production.

Connected digital systems transform manufacturing from sequential departmental handoffs to simultaneous, coordinated activities.

What digital workflow automation reduces administrative delays?

Manual order processing, production planning, and quality documentation create significant administrative delays in traditional manufacturing. Our digital workflow automation instantly routes information between systems and personnel without manual intervention. When orders are received, the system automatically generates manufacturing instructions, reserves materials, and schedules production without human processing time. During production, the system provides real-time progress tracking that enables immediate response to issues rather than waiting for end-of-shift reports. This administrative acceleration has reduced our order-to-production launch time from 2-3 days to under 4 hours, providing significant competitive advantage in time-sensitive markets.

How does machine-to-machine communication optimize production flow?

Traditional manufacturing requires human monitoring and adjustment to coordinate different equipment and processes. Our industrial IoT systems enable direct machine-to-machine communication that optimizes production flow automatically. When one process completes a batch, it automatically signals downstream equipment to prepare for the next operation. Machines collectively balance production speeds to prevent bottlenecks and automatically adjust parameters based on real-time conditions. This continuous coordination has increased our overall equipment effectiveness by 35% while eliminating the manual adjustment and monitoring time previously required to maintain smooth production flow between different manufacturing stages.

How does automated quality control accelerate production velocity?

Traditional quality inspection creates significant time delays through sampling, manual checking, and defect correction cycles. Automated quality systems transform inspection from a separate, time-consuming activity to an integrated, instantaneous process that prevents defects rather than detecting them after completion.

In-line quality automation maintains production speed while ensuring consistent quality standards.

What in-process inspection prevents later corrections?

Traditional quality control typically occurs after completion, allowing defective products to consume full production time before rejection. Our in-process automated inspection verifies quality at each manufacturing stage, immediately flagging issues as they occur. Vision systems check components upon arrival, during assembly, and after completion without slowing production flow. When issues are detected, the system immediately alerts operators or, in advanced implementations, triggers automatic corrections. This approach has reduced our scrap and rework rate by 75% while eliminating the time previously wasted completing defective products that would ultimately be rejected.

How does predictive quality analysis prevent production delays?

Beyond detecting current defects, advanced systems predict and prevent future quality issues that would cause production delays. Our predictive quality algorithms analyze production data to identify conditions likely to cause defects, enabling preemptive adjustments before issues occur. The system might detect that specific material lots require modified processing parameters or that equipment needs calibration before quality drifts beyond tolerance. This predictive approach has reduced unexpected quality-related downtime by 60% while maintaining consistent production velocity through prevented disruptions. The system continuously learns from production outcomes, improving its predictive accuracy and further optimizing production speed over time.

Conclusion

Automated systems are enhancing hair accessory production speed by fundamentally reengineering manufacturing processes to eliminate time constraints inherent in traditional methods. The combination of robotic assembly, automated material handling, digital integration, and in-process quality control creates production ecosystems that operate at speeds impossible to achieve through manual approaches. Manufacturers implementing these automated systems achieve significant competitive advantages through faster time-to-market, increased production capacity, and improved responsiveness to customer demands while maintaining or enhancing product quality.

If you're looking to enhance your hair accessory production speed through automation, we invite you to contact our Business Director, Elaine. Our experience in implementing automated systems across diverse hair accessory categories can help you achieve similar speed improvements and competitive advantages. Reach her at: elaine@fumaoclothing.com.