The manufacturing of precision-stitched leather belts involves numerous complex processes where optimal resource allocation directly impacts quality, cost, and production efficiency. Traditional resource planning relies heavily on experienced managers making decisions based on historical data and intuition, often leading to material waste, labor inefficiencies, and production bottlenecks. The unique characteristics of leather—natural variations, different grades, and specific handling requirements—make resource allocation particularly challenging.

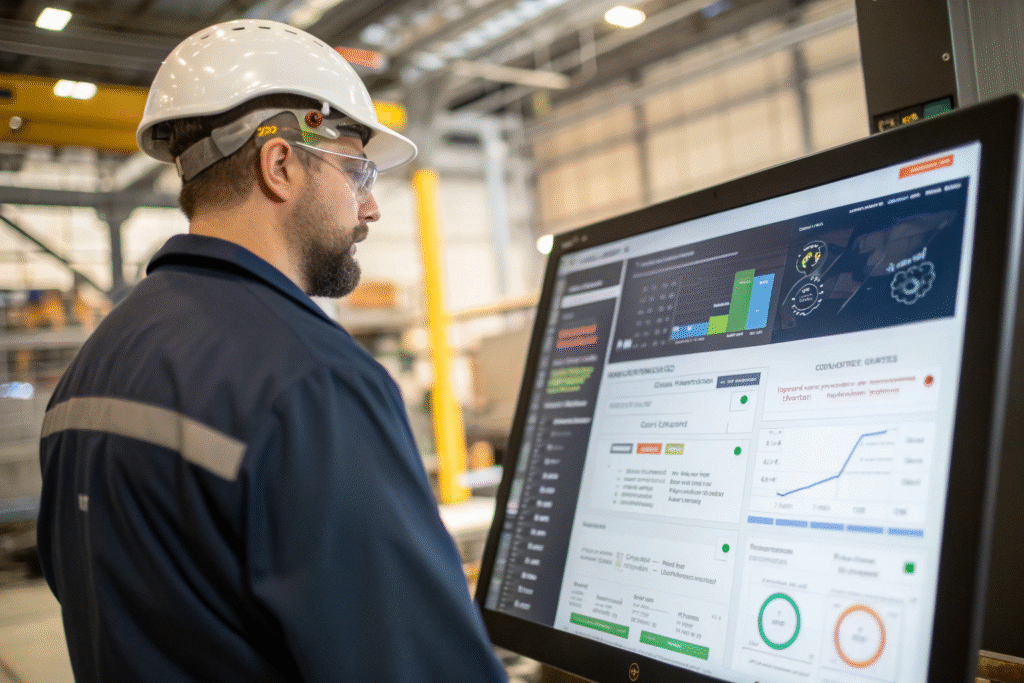

AI tools are revolutionizing resource allocation for precision-stitched leather belts by analyzing multiple variables in real-time, predicting material requirements with unprecedented accuracy, optimizing workforce deployment, and minimizing waste through predictive analytics.These systems transform resource management from reactive decision-making to proactive optimization that balances quality, cost, and throughput across the entire manufacturing process.

Let's examine the specific ways AI tools enhance resource allocation and the tangible benefits they deliver in leather belt manufacturing.

How does AI optimize leather material utilization?

Leather represents the most significant cost component in belt manufacturing, with traditional cutting methods often achieving only 70-75% material utilization due to natural hide irregularities and manual pattern placement. The premium nature of leather suitable for precision stitching makes waste reduction particularly valuable, as every square inch of unused material represents lost value.

AI systems transform material allocation from art to science through advanced analysis and optimization algorithms.

What makes AI nesting superior to manual pattern placement?

Computer vision hide analysis combined with generative design algorithms evaluates thousands of potential cutting patterns to maximize usable material from each hide. Our implementation scans each hide for natural imperfections, thickness variations, and stretch characteristics before generating optimal cutting patterns that achieve 92-95% material utilization. This precision allocation has reduced our leather costs by 28% while actually improving quality by ensuring belt sections are cut from the most appropriate hide areas based on their structural characteristics.

How does AI predict leather requirements across production runs?

Demand-based material forecasting analyzes order patterns, hide characteristics, and production schedules to optimize leather purchasing and allocation across multiple production runs. Our system has reduced leather inventory by 35% while eliminating production delays due to material shortages through more accurate consumption prediction and strategic hide selection. This predictive procurement has been particularly valuable for managing the natural variations in leather supply and ensuring consistent quality across production batches.

How does AI enhance workforce allocation and skill matching?

Precision-stitched belt manufacturing requires different skill levels for various production stages—from hide selection and cutting to stitching, finishing, and quality control. Traditional workforce allocation often relies on fixed assignments or manager discretion, which may not optimally match skills with current production needs or account for variable workflow requirements.

AI-driven workforce management creates dynamic skill matching that improves both efficiency and quality outcomes.

How does AI match operator skills with production requirements?

Skill-based task allocation analyzes individual operator capabilities, historical performance data, and current order specifications to assign the most appropriate workers to each production stage. Our implementation has improved first-pass quality yield by 23% by ensuring complex stitching patterns are assigned to our most experienced stitchers, while simpler tasks are allocated to appropriate skill levels. This precision matching has also reduced training time for new operators by providing them with appropriately challenging assignments that match their developing skills.

What role does predictive scheduling play in workforce optimization?

Demand-aware labor planning forecasts production requirements and automatically schedules appropriate workforce levels, skills, and shifts to match order volumes and complexities. Our system has reduced overtime costs by 42% while improving on-time completion from 79% to 96% through better alignment of workforce capacity with production needs. This intelligent scheduling has been particularly valuable during seasonal peaks when traditional methods often either overstaffed (increasing costs) or understaffed (causing delays).

How does AI optimize equipment and tooling allocation?

Precision stitching requires specialized equipment—from automated stitching machines and skiving equipment to cutting dies and finishing tools—that represents significant capital investment. Traditional equipment allocation often follows fixed schedules that don't account for variable maintenance needs, order priorities, or equipment performance characteristics.

AI-driven equipment management ensures optimal utilization while maintaining quality standards and preventing downtime.

How does AI improve stitching machine allocation?

Performance-based equipment assignment matches machine capabilities with order requirements, considering factors like stitch complexity, leather thickness, and production urgency. Our system has increased equipment utilization from 68% to 87% by dynamically allocating orders to machines based on their specific capabilities and current condition rather than using a simple rotation system. This capability matching has been particularly valuable for our premium collection where consistent stitch quality is critical and different machines perform better with specific leather types and stitch patterns.

What maintenance optimization benefits does AI provide?

Predictive maintenance scheduling analyzes equipment sensor data to identify maintenance needs before they affect production quality or cause unplanned downtime. Our implementation has reduced unplanned equipment downtime by 76% by predicting maintenance needs based on actual usage patterns rather than fixed schedules. This proactive maintenance has been especially important for our precision stitching equipment where gradual performance degradation can affect stitch consistency long before complete failure occurs.

How does AI enhance time and production flow allocation?

The manufacturing process for precision-stitched belts involves multiple sequential stages where bottlenecks in any single stage can delay entire production runs. Traditional production planning often uses fixed time allocations that don't account for variable complexity, material characteristics, or unexpected issues.

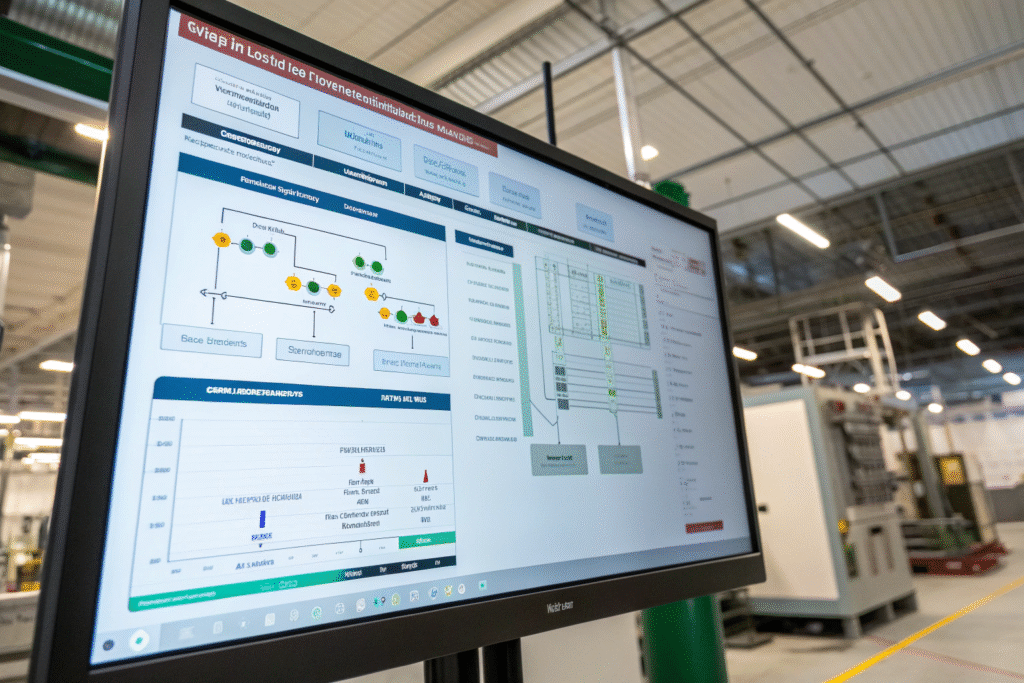

AI-driven production flow optimization creates dynamic scheduling that adapts to real-time conditions and priorities.

How does AI optimize production sequencing?

Dynamic bottleneck prediction identifies potential constraints before they impact production and resequences orders to maintain smooth workflow. Our system has reduced average order completion time by 34% by identifying and addressing potential bottlenecks in real-time rather than reacting to delays after they occur. This proactive sequencing has been particularly valuable for handling rush orders and custom requests without disrupting standard production flow.

What time allocation benefits does AI provide for complex orders?

Complexity-based time estimation accurately predicts processing time for different order types based on historical data and current conditions. Our implementation has improved delivery date accuracy from 74% to 94% by accounting for factors like leather type, stitch complexity, hardware requirements, and current workload when estimating completion times. This precision scheduling has significantly reduced the expedited shipping costs previously needed to compensate for inaccurate time estimates.

Conclusion

AI tools are fundamentally enhancing resource allocation for precision-stitched leather belts by bringing data-driven precision to decisions that were previously based on experience and intuition. Through optimized material utilization, intelligent workforce management, efficient equipment allocation, and dynamic production flow optimization, AI systems deliver significant improvements in cost efficiency, quality consistency, and production throughput.

The manufacturers that embrace these AI capabilities are building sustainable competitive advantages through better resource management that balances quality preservation with economic efficiency. As the technology continues to advance and become more accessible, AI-powered resource allocation will evolve from competitive differentiator to essential capability in premium leather goods manufacturing.

If you're interested in implementing AI tools for your leather belt production resource allocation or want to partner with a manufacturer that has advanced AI capabilities, we invite you to contact our Business Director, Elaine. She can discuss our AI implementation and how it delivers superior resource optimization for precision leather goods. Reach her at: elaine@fumaoclothing.com.