The jewelry industry, particularly pendant manufacturing, has long relied on traditional craftsmanship and manual quality control. However, these methods often struggle with consistency, precision, and scaling production while maintaining excellence. At our factory, we've integrated AI algorithms into our pendant production processes, achieving remarkable improvements in both artistic quality and manufacturing consistency that traditional methods cannot match.

AI algorithms are revolutionizing pendant craftsmanship and quality standards by enabling unprecedented precision in design execution, detecting microscopic flaws human eyes miss, optimizing material usage, and predicting production issues before they occur.This technological integration represents not a replacement of human skill but an enhancement that elevates both artistic potential and quality consistency.

The transformation happening in pendant manufacturing through AI represents a fundamental shift in how quality and craftsmanship are achieved. Let's explore the specific mechanisms through which AI algorithms are driving this revolution in accessory production.

How is AI transforming design precision and complexity?

Traditional pendant design faces limitations in executing highly complex patterns and maintaining exact precision across production runs. Human designers and artisans, no matter how skilled, encounter natural variations that affect consistency, especially in intricate designs.

AI algorithms overcome these limitations through computational design capabilities that enhance both creative possibilities and manufacturing precision, enabling designs previously considered impossible or economically unviable.

What computational design capabilities does AI enable?

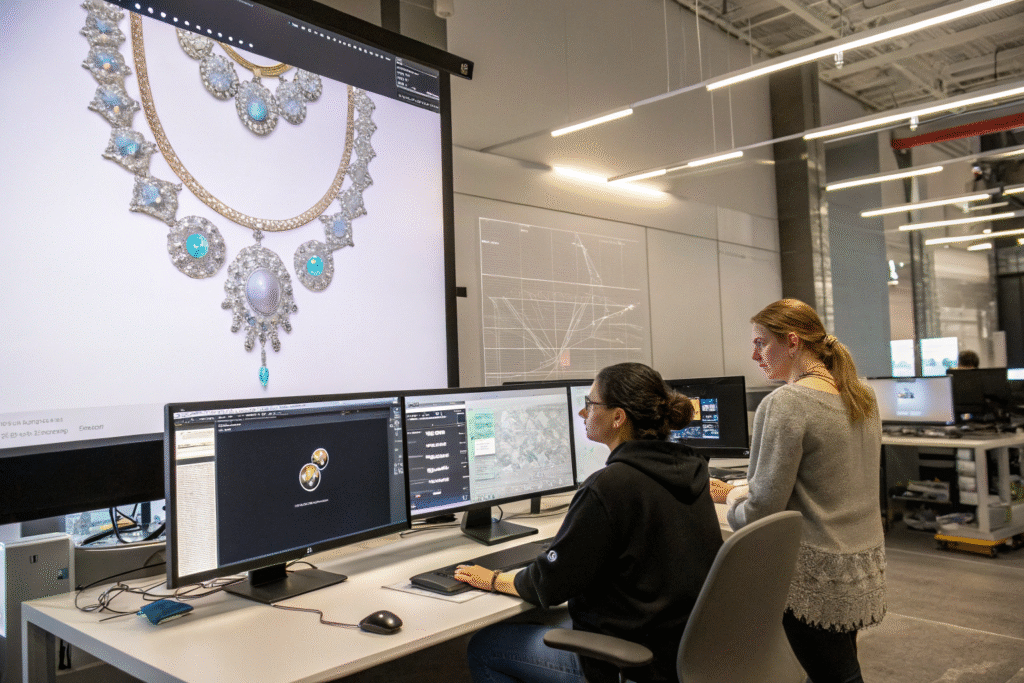

AI-powered design systems can generate and refine complex patterns beyond human conceptualization capacity. Our generative design algorithms create intricate pendant patterns by processing thousands of design iterations based on specified parameters like style, complexity level, and material constraints. These systems identify optimal design elements that maximize aesthetic appeal while ensuring manufacturing feasibility. For custom pendant collections, our AI tools analyze customer preference data to suggest design modifications that increase market appeal while maintaining brand identity. This data-driven approach has reduced our design-to-production time by 45% while increasing design success rates in market testing.

How does AI enhance precision in design execution?

Manual translation of designs into manufacturing specifications introduces subtle variations that affect quality consistency. Our AI-driven design execution systems convert digital designs into precise manufacturing instructions with micron-level accuracy. These algorithms automatically adjust for material characteristics, tooling limitations, and production constraints that human designers might overlook. For complex filigree work or micro-engraving, the AI calculates optimal tool paths and sequencing that minimize material stress and maximize detail preservation. This precision ensures that every pendant in a production run matches the original design exactly, eliminating the variations that traditionally plagued jewelry manufacturing.

How do AI quality detection systems surpass human capabilities?

Quality control in pendant manufacturing has traditionally relied on trained human eyes, which despite their expertise, suffer from fatigue, inconsistency, and inability to detect microscopic flaws consistently across large production runs.

AI vision systems bring superhuman consistency, precision, and endurance to quality assessment, detecting flaws at scales and speeds impossible for human inspectors while learning and improving continuously.

What microscopic flaw detection can AI achieve?

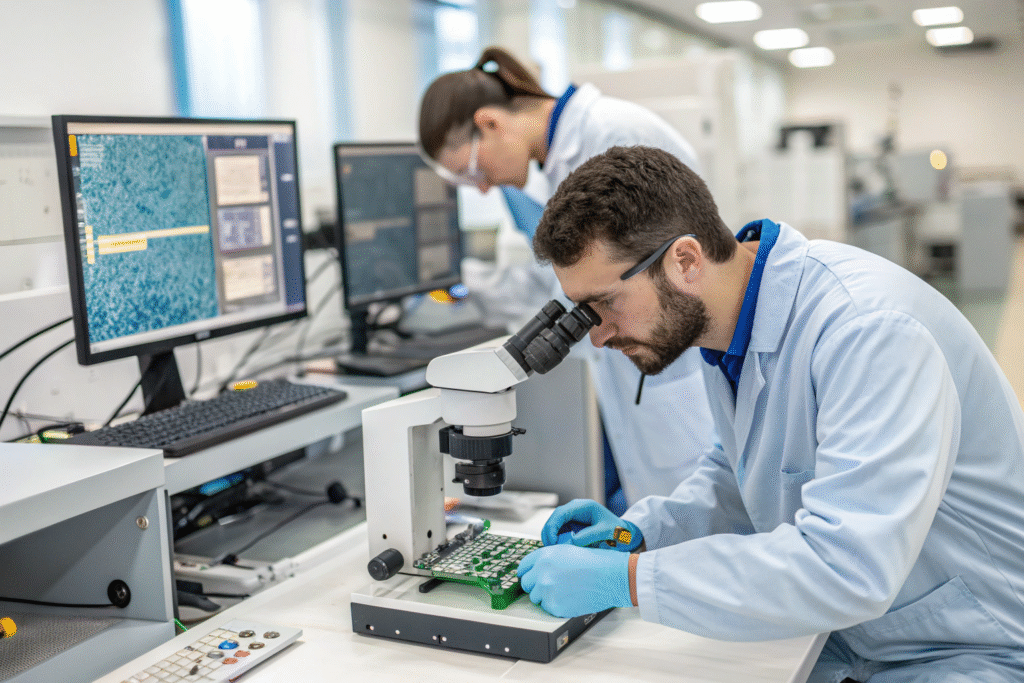

Human vision has natural limitations in detecting sub-millimeter imperfections, especially in reflective metals and intricate pendant designs. Our AI-powered visual inspection systems utilize high-resolution cameras and machine learning algorithms trained on thousands of annotated flaw examples. These systems detect imperfections like micro-scratches, uneven plating, stone setting irregularities, and microscopic casting defects that escape human notice. The AI evaluates each pendant from multiple angles and lighting conditions, creating a comprehensive quality assessment far beyond human capability. This microscopic scrutiny has reduced customer returns for quality issues by over 70% since implementation.

How does AI ensure consistency across production batches?

Human quality assessment naturally varies based on inspector experience, fatigue levels, and subjective standards. Our AI consistency algorithms maintain identical quality standards 24/7, applying the same rigorous criteria to every pendant regardless of production batch size or timing. The systems track quality metrics across production runs, identifying subtle trends that might indicate developing equipment issues or material inconsistencies. This continuous monitoring prevents the gradual quality drift that often occurs in traditional manufacturing, where standards may unconsciously lower during high-pressure production periods. The result is unwavering quality consistency that builds brand trust and customer loyalty.

How is AI optimizing material usage and sustainability?

Pendant manufacturing traditionally generates significant material waste through imprecise cutting, casting imperfections, and design inefficiencies. This waste represents both environmental concerns and substantial cost inefficiencies that impact product pricing and sustainability credentials.

AI algorithms dramatically reduce material waste through precise calculation, predictive modeling, and optimization algorithms that maximize material utilization while maintaining design integrity.

What computational nesting reduces material waste?

Traditional material cutting and casting layouts often waste precious metals and stones due to suboptimal arrangement. Our AI nesting algorithms calculate the most efficient material layouts for pendant production, considering grain directions, stress points, and aesthetic requirements. For metal sheet cutting, these systems achieve material utilization rates exceeding 90%, compared to 60-70% with manual layout methods. For stone setting, the AI calculates optimal placement that minimizes cutting waste while maximizing visual impact. This precision not only reduces material costs but also supports our sustainability initiatives by minimizing environmental impact—a growing concern for conscious consumers.

How does AI predict and prevent material defects?

Material-related defects often appear only after significant processing, resulting in wasted labor and materials. Our predictive material algorithms analyze raw material characteristics and forecast potential issues before manufacturing begins. For casting alloys, the AI predicts shrinkage areas and recommends modifications to prevent voids. For stone selection, it identifies inclusions and structural weaknesses that might cause future failures. This predictive capability allows us to either reject problematic materials upfront or adjust manufacturing parameters to accommodate material peculiarities. The result is significantly higher first-pass yield rates and reduced rework, contributing to both quality improvement and cost reduction.

How does AI enhance artisan skills and capabilities?

Rather than replacing human artisans, AI serves as an augmentation tool that enhances their capabilities, reduces repetitive tasks, and provides data-driven insights that inform skilled craftsmanship decisions.

This human-AI collaboration creates a new category of enhanced craftsmanship where human creativity and intuition combine with AI precision and analytical power.

What skill augmentation does AI provide artisans?

Even highly skilled artisans benefit from AI assistance in complex tasks. Our augmented reality guidance systems overlay digital templates and instructions onto physical workpieces, guiding artisans through complex procedures with perfect precision. For intricate engraving or stone setting, these systems provide real-time feedback on tool angle, pressure, and positioning—functioning like a master craftsperson looking over the artisan's shoulder. This augmentation reduces errors in complex operations and accelerates skill development for junior artisans. The AI also logs successful techniques, creating a knowledge base that preserves expert methods and makes them accessible to the entire production team.

How does AI-driven training accelerate skill development?

Traditional artisan training requires years of mentorship to achieve mastery. Our AI-powered training systems accelerate this process by providing immediate, objective feedback on technique quality. Trainees practice on simulated materials while the AI analyzes their movements, identifying inefficiencies or errors that human instructors might miss. The system creates personalized training paths addressing each artisan's specific development needs. This accelerated skill development has reduced our training time by approximately 40% while producing artisans with more consistent technique and deeper understanding of both traditional craftsmanship and modern manufacturing principles.

Conclusion

AI algorithms are fundamentally enhancing pendant craftsmanship and quality standards by bringing unprecedented levels of precision, consistency, and efficiency to processes that have remained largely unchanged for centuries. This technological integration doesn't diminish the role of human artisans but rather elevates their capabilities, allowing them to focus on creative aspects while AI handles repetitive precision tasks and quality verification. The result is a new era in jewelry manufacturing where exceptional quality becomes consistently achievable at scale, and artistic possibilities expand beyond previous limitations.

If you're interested in leveraging AI technologies to enhance your pendant collections' craftsmanship and quality standards, we invite you to contact our Business Director, Elaine. Our successful integration of AI systems with traditional jewelry manufacturing has positioned us at the forefront of this manufacturing revolution. Reach her at: elaine@fumaoclothing.com.