Fashion accessory manufacturing has traditionally relied heavily on skilled manual labor for tasks like assembly, stitching, and quality inspection. While human craftsmanship brings artistry to the process, it inevitably introduces variations in output quality. Different workers, fatigue factors, and shifting attention levels mean that no two hand-produced items are perfectly identical, leading to consistency challenges in large production runs.

Advanced robotics enhance production consistency in fashion accessory manufacturing by performing repetitive tasks with micron-level precision, maintaining unwavering quality standards 24/7, and eliminating human variability factors.These systems combine sophisticated sensors, AI-powered vision systems, and precise actuation to deliver identical results across thousands of production cycles, ensuring every hair clip, bracelet, or scarf meets exact specifications.

Let's examine how robotics technologies are transforming quality standards across different accessory categories and manufacturing processes.

How do robotic systems achieve superior precision in accessory production?

Human hands, no matter how skilled, have natural limitations in achieving perfect consistency. Slight variations in pressure, alignment, or material handling can create noticeable differences in finished accessories, particularly in items requiring exact symmetry or precise component placement.

Robotic systems overcome these limitations through programmed precision, sophisticated feedback mechanisms, and tireless repetition that eliminates the subtle variations introduced by human factors.

What level of precision can robotics achieve in accessory manufacturing?

Advanced robotics can position components with accuracy up to 10 micrometers - far beyond human capability. This precision is particularly valuable for operations like setting stones in hair accessories, attaching clasps to necklaces, or aligning patterns on printed scarves. For example, our robotic assembly systems for decorative hair clips place rhinestones with exact positioning and consistent adhesive application, ensuring every item matches the design specification perfectly. This eliminates the visible variations that occur with manual placement.

How do vision-guided robots enhance manufacturing accuracy?

Robotic vision systems use high-resolution cameras and pattern recognition algorithms to identify component positions and orientations before manipulation. This allows robots to adapt to natural variations in material placement while maintaining perfect execution. In our belt buckle production line, vision-guided robots consistently align embossed patterns and attach fasteners with exact positioning, regardless of how components are presented. This combination of flexibility and precision is impossible to achieve through purely manual processes.

How do robotics maintain consistent quality over extended production runs?

Human performance naturally fluctuates due to fatigue, distraction, and shifting concentration levels throughout a work shift. These variations directly impact product quality, often resulting in higher defect rates at the end of long shifts or during repetitive tasks.

Robotic systems deliver identical performance on the first unit as on the thousandth, maintaining precise speed, pressure, and positioning regardless of production duration or complexity.

What makes robotic systems immune to performance degradation?

Unlike human workers who experience muscle fatigue and attention drift, industrial robots maintain programmed parameters indefinitely. Their electric servomotors deliver identical torque and speed for each operation, while position sensors verify correct execution every cycle. This consistency is particularly valuable for operations like stitching leather bags or assembling multi-component hair accessories where tension and alignment must remain constant. Our data shows robotic sewing cells maintain stitch length within 0.1mm variation throughout 24-hour production runs.

How do robotics handle complex repetitive tasks without variation?

Complex assembly processes requiring multiple sequential steps are particularly prone to human error through skipped steps or incorrect sequencing. Robotic workcells execute programmed routines with perfect repetition, ensuring every accessory receives identical treatment. For our embellished headband production, robotic systems consistently apply the exact same pattern of adhesives, decorative elements, and finishing touches to each item. This eliminates the subtle variations that occur when different workers interpret the same design specifications.

How do robotic quality inspection systems enhance consistency?

Human visual inspection becomes less reliable over time as fatigue sets in, and subtle defects may be overlooked during high-volume production. Even experienced quality controllers can miss minor variations in color, texture, or dimensions when examining hundreds of similar items.

Robotic inspection systems combine high-resolution imaging, sophisticated algorithms, and measurable standards to identify defects and variations that escape human detection.

What types of defects can robotic vision systems detect?

Automated inspection robotics can identify color variations as small as 1% deviation from standard, dimensional inaccuracies down to 0.01mm, surface defects like scratches or imperfections, and assembly errors like missing components. In our scarf production, robotic vision systems detect weaving inconsistencies and printing alignment issues that would be virtually invisible to human inspectors during rapid visual checks. This comprehensive inspection ensures only perfect products reach customers.

How does robotic inspection provide objective quality standards?

Human quality assessment inevitably involves subjective judgment, with different inspectors applying slightly different standards. Robotic quality control establishes absolute, measurable parameters for acceptance or rejection. For example, our system for examining metallic accessories uses predefined reflectance standards and geometric measurements rather than subjective "looks right" assessments. This objectivity eliminates the consistency challenges that occur when multiple inspectors evaluate the same products using their individual criteria.

How do collaborative robots enhance human workers' consistency?

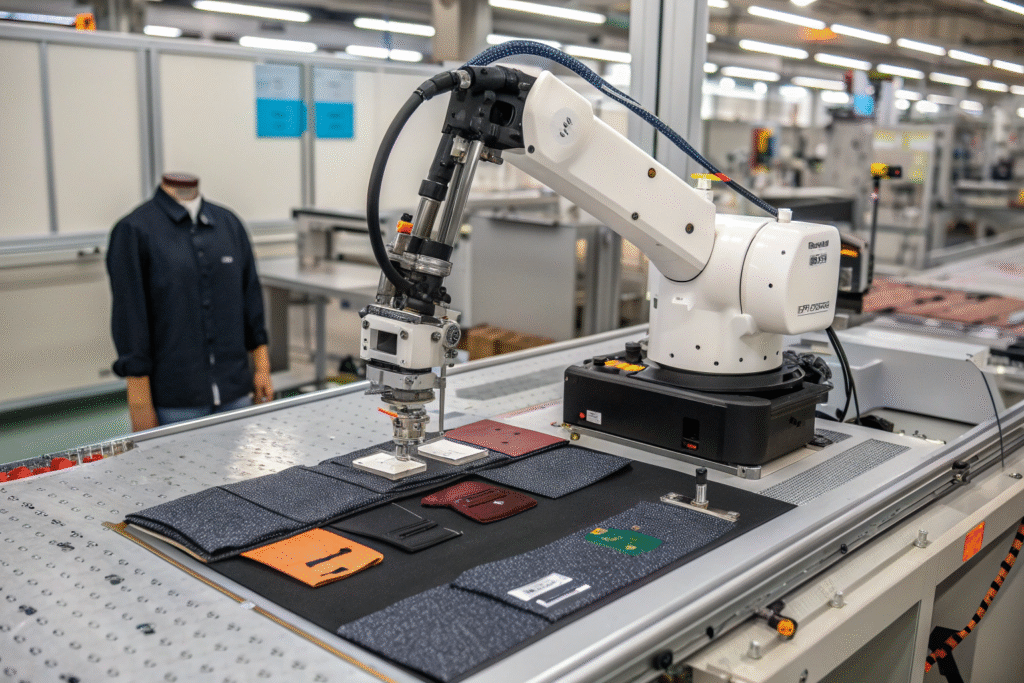

Traditional automation often completely replaces human workers, but collaborative robots (cobots) work alongside people, enhancing their capabilities while reducing the physical and cognitive demands that lead to inconsistent output.

These systems combine human creativity and adaptability with robotic precision and endurance, creating hybrid workcells that maximize the strengths of both approaches.

What tasks are ideal for human-robot collaboration in accessory manufacturing?

Operations requiring both creative judgment and repetitive precision benefit greatly from collaborative robotics. For example, in our custom jewelry department, human designers handle creative arrangement and aesthetic decisions while cobots perform the precise soldering, stone setting, and polishing operations. This partnership ensures the artistic vision is perfectly executed every time, without the variations that occur when artisans perform both creative and highly repetitive tasks.

How do cobots reduce physical strain that causes inconsistency?

Repetitive strain and fatigue directly impact workers' ability to maintain consistent quality throughout their shifts. Collaborative robots handle the physically demanding aspects of production - lifting, positioning, and repetitive motions - while human workers focus on tasks requiring judgment and dexterity. In our bag assembly line, cobots position and hold materials while workers perform detailed stitching and finishing. This ergonomic approach has reduced quality variations by 27% by minimizing worker fatigue.

Conclusion

Advanced robotics are fundamentally transforming production consistency in fashion accessory manufacturing by eliminating the human variability factors that inevitably affect manual processes. Through precise repetition, sophisticated sensing, and tireless operation, robotic systems ensure that every hair accessory, piece of jewelry, or fashion item meets exact quality standards regardless of production volume or duration.

As these technologies continue to advance and become more accessible, they're enabling manufacturers to deliver unprecedented consistency while maintaining the design creativity and artistry that define fashion accessories. This combination of technological precision and human creativity represents the future of accessory manufacturing.

If you're interested in partnering with a manufacturer that utilizes advanced robotics to ensure consistent quality across all production runs, we invite you to contact our Business Director, Elaine. She can discuss our robotic capabilities and how they ensure your accessory designs are produced with perfect consistency. Reach her at: elaine@fumaoclothing.com.