The fashion accessory market moves rapidly, with trends emerging and fading sometimes within a single season. Traditional linear production systems struggle with this pace, often causing manufacturers to miss key selling windows or overproduce items that have already fallen out of fashion. The rigid nature of these conventional systems creates significant bottlenecks when shifting between product types or implementing design changes.

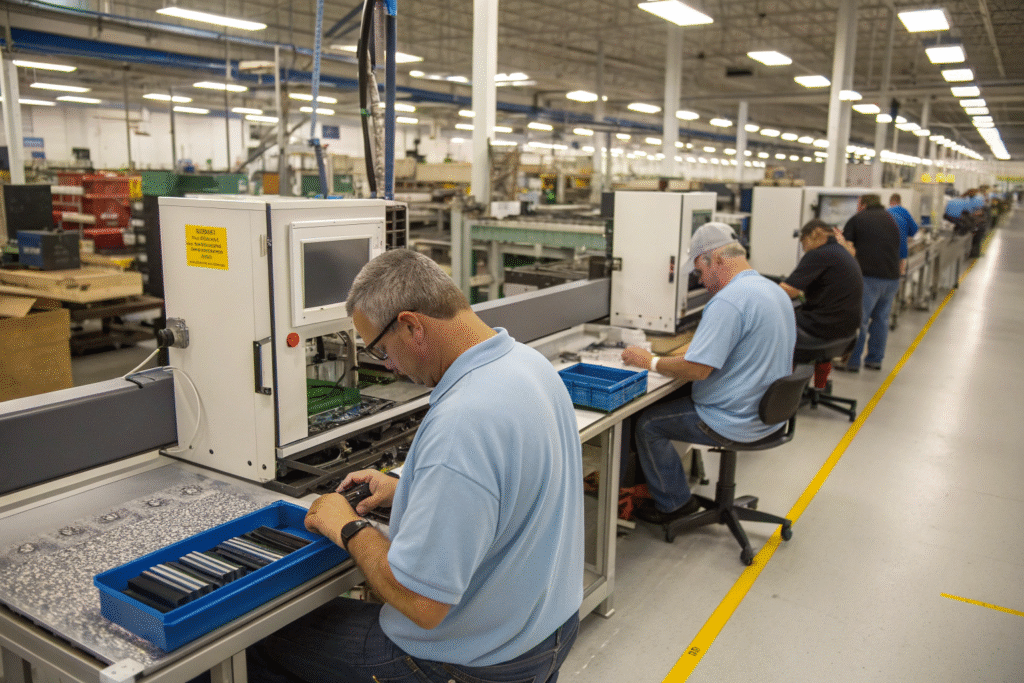

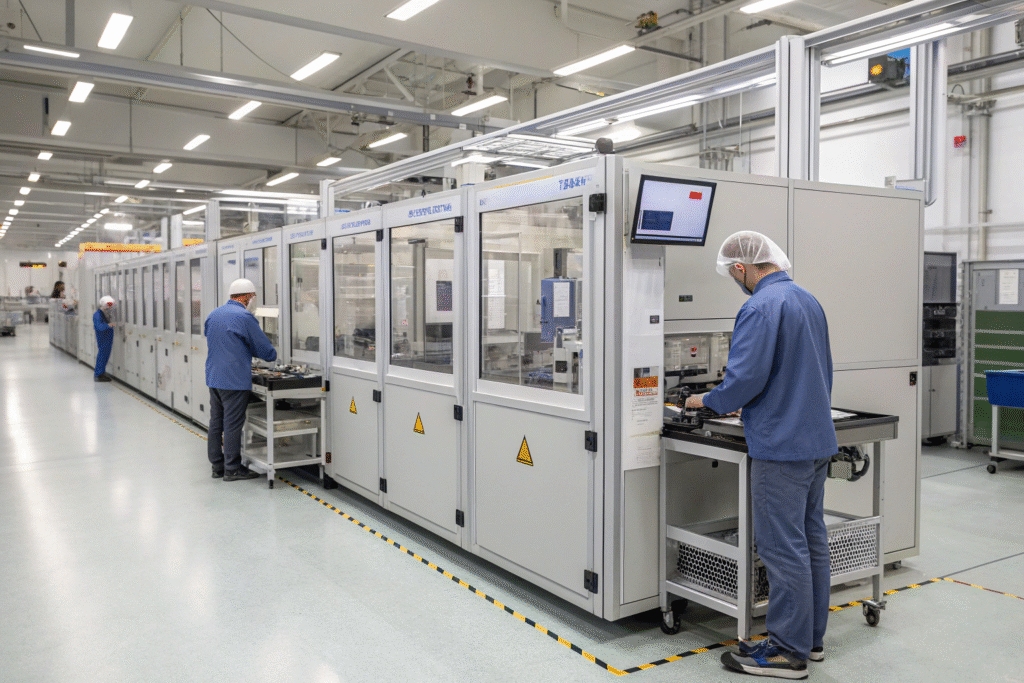

Modular production systems transform accessory manufacturing through flexible workstations, reconfigurable layouts, and standardized processes that enable rapid product changeovers, mixed-model production, and scalable capacity.This approach organizes manufacturing around self-contained modules that can be easily rearranged or modified to accommodate different products, volumes, and customization requirements without major downtime or retooling investments.

Let's explore the specific advantages this manufacturing philosophy brings to fashion accessory production across various product categories and business scenarios.

How do modular systems enhance production flexibility for accessory manufacturers?

Traditional production lines are typically dedicated to specific products, creating significant inefficiencies when demand patterns shift or new designs are introduced. Changing over a dedicated line often requires days of downtime and substantial retooling costs, making small batch production economically challenging.

Modular production organizes manufacturing around flexible work cells that can be quickly reconfigured for different products, enabling manufacturers to respond to market changes within hours rather than weeks.

What makes modular systems so adaptable to product changes?

Modular production systems utilize standardized equipment interfaces, mobile workstations, and universal tooling that can be rapidly rearranged for different accessory types. For example, the same work cell that assembles beaded bracelets in the morning can be reconfigured to produce embellished hair clips in the afternoon by simply changing fixture plates and component bins. This production flexibility allows us to shift between our 15 different accessory categories with changeover times under two hours, compared to the 2-3 days required with our previous dedicated line approach.

How do modular systems handle variable batch sizes efficiently?

The cellular nature of modular manufacturing enables parallel processing of multiple small batches simultaneously. Instead of requiring minimum economic quantities to justify line setup, manufacturers can profitably produce lots as small as 50-100 units by dedicating a single module to that product. This capability is particularly valuable for testing new designs, fulfilling custom orders, and producing seasonal variations without the inventory risks associated with large production runs. Our current system efficiently handles batch sizes ranging from 50 to 5,000 units of the same accessory design.

How do modular systems reduce costs in accessory production?

Conventional manufacturing often requires significant capital investment in specialized equipment for each product category, creating high fixed costs that must be spread across production volumes. This economic model favors large batch production regardless of actual market demand, leading to either stockouts of popular items or excessive inventory of slower-moving products.

Modular systems achieve cost efficiency through equipment utilization optimization, reduced changeover expenses, lower inventory carrying costs, and minimized capital investment in specialized machinery.

What specific cost savings do modular systems deliver?

Modular production reduces equipment costs by utilizing multi-purpose machines that serve multiple product categories instead of dedicated single-function equipment. The reduced changeover time directly decreases labor costs during product transitions. Perhaps most significantly, the ability to produce in response to actual demand rather than forecasts dramatically reduces inventory carrying costs and markdown expenses. Our implementation of modular principles cut our inventory levels by 42% while actually improving our order fulfillment rate from 87% to 96%.

How does modular manufacturing minimize capital investment?

Traditional accessory manufacturing requires separate equipment sets for different product categories - specific machines for metal stamping, plastic injection, sewing, etc. Modular systems utilize universal base machines with quick-change tooling and fixtures, allowing a single capital investment to serve multiple production needs. For example, our standardized press systems can produce everything from metal bracelet components to plastic hair clip bases simply by changing the dies and fixtures. This approach reduced our equipment investment by approximately 30% while increasing our overall production capacity.

How do modular systems improve scalability for growing businesses?

Accessory brands often experience unpredictable growth patterns, with certain products suddenly gaining popularity and requiring rapid production scaling. Traditional manufacturing systems struggle with this variability, either requiring expensive excess capacity to handle peaks or causing stockouts during demand surges.

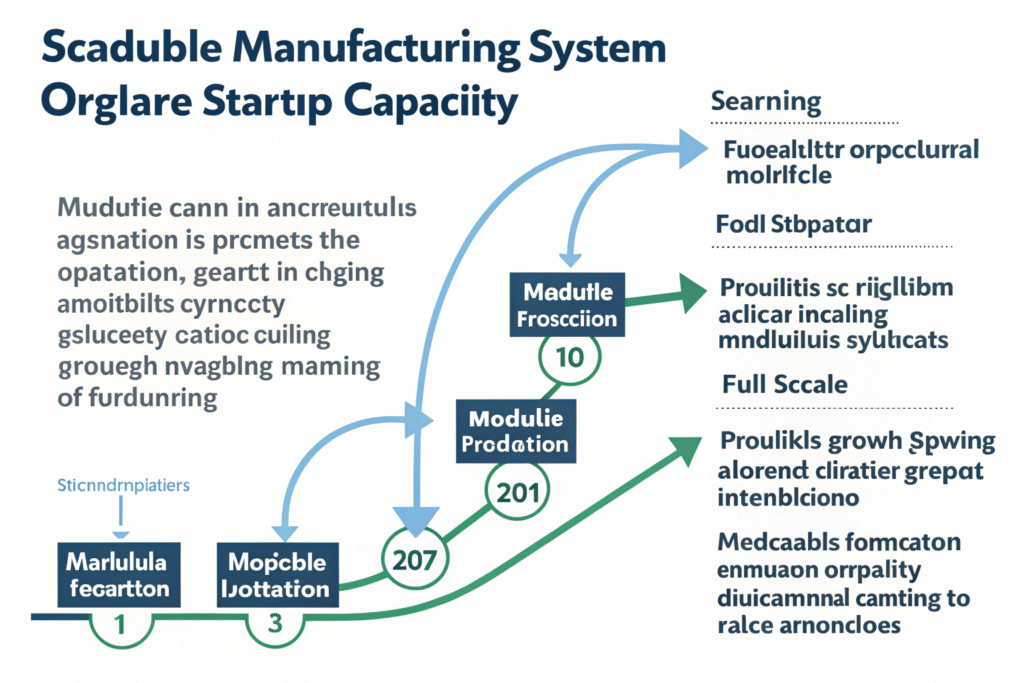

Modular production enables granular scalability by allowing manufacturers to add capacity in small increments exactly where needed, rather than in large, expensive chunks.

How does modular design support business growth phases?

Modular production systems grow organically with business needs. A startup might begin with 2-3 basic modules covering their initial product range, then add specialized modules as their assortment expands. This incremental approach spreads capital investment over time and ensures capacity matches actual demand. For our growing clients, we've developed a scalable production model where they can start with a single modular cell for their core products and expand module-by-module as their business grows, avoiding the massive upfront investment of traditional factory setup.

What scaling advantages do modular systems offer for product line expansion?

When introducing new accessory categories, modular manufacturers can simply reconfigure existing modules or add specialized modules without disrupting current production. This flexibility proved invaluable when we expanded from hair accessories into small leather goods - we added two new modules specifically for leather working while slightly modifying three existing modules to handle shared components. The entire expansion was completed in three weeks with minimal disruption to our ongoing hair clip production, compared to the 2-3 month setup time traditional approaches would have required.

How do modular systems enhance quality control in accessory production?

Traditional assembly lines can create quality challenges when problems emerge, as issues may affect hundreds of units before detection. The linear flow also makes it difficult to implement immediate corrective actions without stopping the entire production process.

Modular manufacturing naturally incorporates quality control at the module level, creating contained quality responsibility and enabling rapid problem identification and resolution.

How does the modular approach improve defect detection and resolution?

Each production module functions as a self-contained quality checkpoint, with operators responsible for the output of their specific process. Problems are immediately apparent within the module rather than propagating downstream. This containment dramatically reduces the impact of quality issues. In our bracelet assembly modules, for example, any emerging issue with clasp attachment is identified and corrected within that module, preventing the problem from affecting more than 5-10 units versus the 50-100 units that might be affected in a traditional linear system.

What quality benefits come from module specialization?

Workers in modular systems develop deep expertise in their specific processes rather than generalized knowledge across many operations. This specialization leads to higher quality execution and more sensitive detection of subtle quality deviations. Our data shows that modules dedicated to specific processes like stone setting or precision stitching achieve 35% higher quality scores than generalized workstations where operators frequently switch between unrelated tasks. The focused nature of modular work allows for continuous refinement of specific skills.

Recraft指令--

Conclusion

Modular production systems offer fashion accessory manufacturers a fundamentally more adaptable, efficient, and responsive approach to manufacturing in an industry characterized by rapid change and diverse product requirements. The benefits of enhanced flexibility, reduced costs, scalable growth, and improved quality control combine to create a significant competitive advantage in today's fast-paced fashion market.

As consumer demands continue to evolve toward greater personalization and faster trend cycles, modular manufacturing principles provide the foundational capability to thrive in this dynamic environment while maintaining cost efficiency and quality standards.

If you're interested in exploring how modular production systems could enhance your accessory manufacturing strategy, we invite you to contact our Business Director, Elaine. She can discuss our modular capabilities and how they can be tailored to your specific product needs and business objectives. Reach her at: elaine@fumaoclothing.com.