Waterproof travel backpacks have become essential gear for modern travelers, outdoor enthusiasts, and urban commuters alike. Understanding the materials used in their construction is crucial for selecting a backpack that offers genuine protection against rain, spills, and accidental submersion. These materials combine technical performance with durability to safeguard valuable belongings in various weather conditions.

Waterproof travel backpacks are primarily constructed from specialized synthetic fabrics with waterproof coatings, laminated membranes, welded seams, and water-resistant components. At AceAccessory,a core brand of shanghaifumaoclothing https://shanghaiGarment.com, our waterproof backpack collections utilize advanced material technologies that undergo rigorous testing to ensure they meet international waterproof standards while maintaining aesthetic appeal and practical functionality for diverse travel needs.

This comprehensive guide examines the primary materials used in waterproof travel backpack construction, exploring their properties, manufacturing processes, and appropriate applications. We'll cover coated fabrics, laminated membranes, waterproof zippers and components, sustainable alternatives, and specialized waterproof treatments.

What Coated Fabrics Provide Primary Waterproof Protection?

Coated fabrics form the first line of defense in waterproof travel backpacks, creating a barrier that prevents water penetration while maintaining flexibility and durability. These materials undergo specialized treatments that enhance their natural water resistance through chemical and mechanical processes.

The most effective coated fabrics include polyurethane-coated polyester, PVC-laminated nylon, and thermoplastic polyurethane (TPU) coatings on various base materials. At AceAccessory, we select coating types and application methods based on the specific performance requirements of each backpack style, ensuring optimal balance between waterproofing, weight, abrasion resistance, and environmental impact.

How Does Polyurethane Coating Create Reliable Water Barriers?

Polyurethane coating creates reliable water barriers through a continuous polymer layer that fills the fabric's inter-yarn spaces, preventing water penetration while maintaining some breathability. Our manufacturing process applies PU coatings in controlled thicknesses—typically 0.5-3.0 mil—depending on the required waterproof rating and flexibility needs. The resulting fabric achieves hydrostatic head ratings of 2,000-10,000 mm, making it suitable for anything from light rain to heavy downpours. The American Society for Testing and Materials (ASTM) provides standardized testing methods that verify these performance claims, ensuring consistent quality across production batches.

Why is TPU Gaining Popularity in Waterproof Backpacks?

Thermoplastic Polyurethane (TPU) is gaining popularity due to its excellent waterproof properties, high flexibility, and environmental advantages over traditional PVC coatings. TPU contains no volatile organic compounds (VOCs) and is recyclable, aligning with growing consumer demand for sustainable products. Our TPU-coated backpacks offer superior cold-weather flexibility, excellent abrasion resistance, and reliable waterproof performance with hydrostatic head ratings typically between 3,000-8,000 mm. This makes them ideal for travelers who encounter varying climate conditions and prioritize eco-conscious purchasing decisions.

What Laminated Membrane Technologies Offer Advanced Protection?

Laminated membrane technologies represent the premium segment of waterproof backpack materials, incorporating microscopic porous films that block liquid water while allowing minimal vapor transmission. These advanced materials provide superior protection in extreme weather conditions while addressing condensation issues.

Key membrane technologies include ePTFE (expanded Polytetrafluoroethylene) like classic Gore-Tex, polyurethane membranes for enhanced flexibility, and electrospun nanofiber laminates for maximum protection. At AceAccessory, our premium backpack collections incorporate these membranes in 2-layer or 3-layer constructions depending on the balance of protection, durability, and packability required.

How Do ePTFE Membranes Provide Breathable Waterproofing?

ePTFE membranes provide breathable waterproofing through a matrix of pores approximately 20,000 times smaller than a water droplet but 700 times larger than a water vapor molecule. This physical barrier principle prevents liquid water penetration while allowing minimal vapor transmission. Our manufacturing partners like Gore-Tex provide certified materials and construction guidelines that ensure every backpack meets strict performance standards. The result is luggage that keeps contents dry in heavy rain while reducing internal condensation, a crucial advantage for protecting electronics and sensitive documents during extended travel.

What Are the Practical Differences Between 2-Layer and 3-Layer Constructions?

The practical differences between 2-layer and 3-layer constructions involve trade-offs between protection, weight, and cost. Three-layer construction sandwiches the membrane between an outer fabric and an inner lining, creating the most durable option ideal for frequently used travel backpacks. Two-layer construction attaches the membrane directly to the outer fabric with a separate hanging liner, offering lighter weight and better packability at a lower price point. Our design team selects the appropriate construction based on the backpack's intended use—3-layer for professional travel gear and 2-layer for casual or occasional-use backpacks where weight and cost are significant considerations.

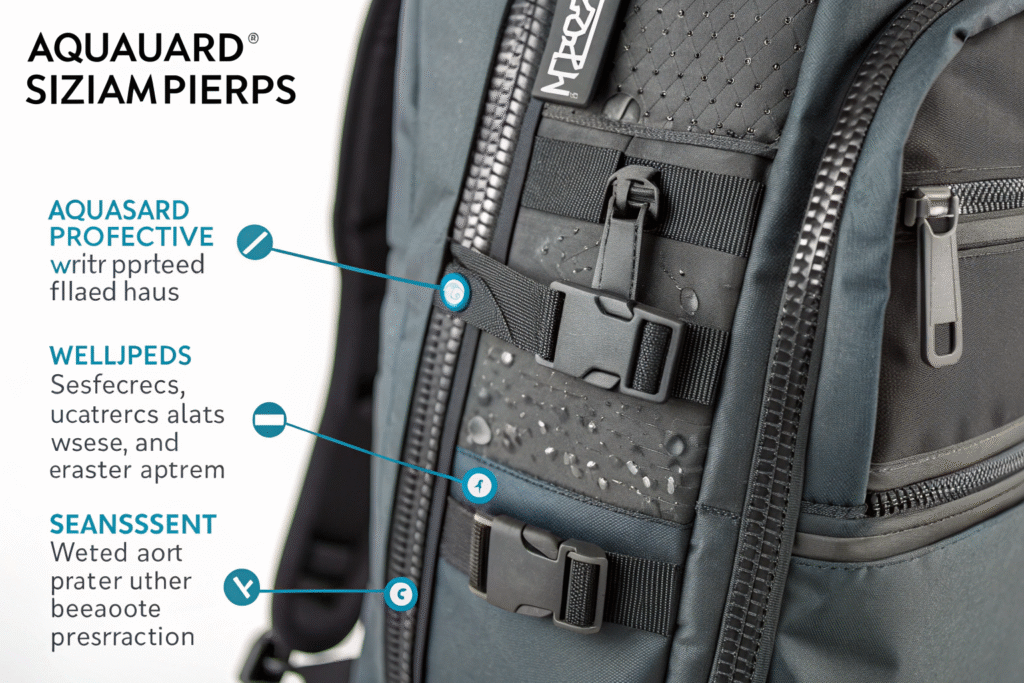

What Components Ensure Complete Waterproof Integrity?

Complete waterproof integrity requires specialized components that work in concert with the main fabric to create a fully water-resistant system. Even the best waterproof fabric can be compromised by poorly designed zippers, seams, or hardware.

Essential waterproof components include aquaguard zippers, welded or taped seams, water-resistant buckles and hardware, and integrated rain covers. At AceAccessory, our waterproof backpacks incorporate these elements through systematic design approaches that address potential water entry points while maintaining user convenience and aesthetic appeal.

How Do Waterproof Zippers Prevent Water Ingress?

Waterproof zippers prevent water ingress through several mechanisms: rubberized or plastic-coated teeth that create a watertight seal when closed, protective flaps that cover the zipper track, and aquaguard designs that incorporate a waterproof membrane behind the zipper teeth. Our backpacks utilize these systems based on the specific protection needs of each compartment, with fully waterproof zippers for critical storage areas and water-resistant versions for less vulnerable sections. This strategic approach ensures maximum protection where needed while maintaining reasonable cost and weight considerations.

Why Are Welded Seams Crucial for Waterproof Performance?

Welded seams are crucial because they eliminate the needle holes created by traditional sewing, which can allow water penetration under pressure. Our welding process uses high-frequency ultrasonic technology that bonds fabric layers at the molecular level, creating completely watertight joins that are often stronger than the surrounding material. This method is particularly important in high-stress areas and the bottom of backpacks where water pressure is greatest. According to testing standards from the International Organization for Standardization (ISO), properly welded seams can increase a backpack's waterproof integrity by up to 90% compared to sewn and taped alternatives.

What Sustainable Waterproof Materials Are Emerging?

Sustainable waterproof materials are increasingly important as consumers seek environmentally responsible products without compromising performance. These emerging alternatives reduce ecological impact while maintaining the protective qualities necessary for reliable travel gear.

Promising sustainable options include recycled nylon and polyester with PFC-free waterproof coatings, bio-based polyurethane derived from renewable resources, and natural fiber blends with advanced water-resistant treatments. At AceAccessory, our eco-friendly collections combine these innovative materials with responsible manufacturing processes, creating backpacks that appeal to environmentally conscious travelers.

How Effective Are PFC-Free Waterproof Coatings?

PFC-free waterproof coatings have become increasingly effective, now achieving hydrostatic head ratings of 1,500-5,000 mm—sufficient for most travel scenarios. These coatings use silicone, wax, or other fluorine-free chemistry to create water-repellent surfaces without the environmental persistence associated with traditional PFCs. Our PFC-free backpacks undergo rigorous testing to ensure they maintain their water resistance through abrasion, folding, and repeated exposure to moisture, providing reliable protection while aligning with the environmental values of modern travelers and the sustainability guidelines of the European Chemicals Agency (ECHA).

Can Recycled Materials Match Virgin Material Performance?

Recycled materials can now match virgin material performance in most key metrics, including waterproof capability, durability, and aesthetic quality. Our recycled nylon and polyester fabrics achieve the same hydrostatic head ratings as their virgin counterparts (typically 3,000-8,000 mm) while reducing resource consumption and environmental impact. Through advanced processing techniques and quality control, we ensure these materials meet the same strict standards for tear strength, abrasion resistance, and colorfastness that travelers expect from premium backpacks, making them a responsible choice without performance compromise.Verify our eco-friendly waterproof backpacks: PFC-free waterproof backpacks, recycled material waterproof backpacks, bulk eco-backpack pricing.

Conclusion

Waterproof travel backpacks utilize a sophisticated combination of coated fabrics, laminated membranes, specialized components, and advanced construction techniques to create reliable protection against moisture. Understanding these materials helps consumers select backpacks that match their specific travel needs, environmental values, and performance expectations. As material technologies continue to evolve, waterproof travel backpacks are becoming increasingly effective, sustainable, and tailored to diverse travel scenarios, offering peace of mind for adventurers navigating unpredictable conditions. To explore bulk pricing, download technical data sheets, or request free product samples for waterproof testing, visit shanghaiGarment.com’s waterproof travel backpack sourcing hub.

If you're interested in sourcing or developing waterproof travel backpacks using any of these material technologies, we invite you to contact our Business Director, Elaine. She and our AceAccessory team specialize in manufacturing travel gear that combines technical performance with market-appropriate styling and sustainable principles. Reach out to Elaine at: elaine@fumaoclothing.com.