Waterproof hats have become essential accessories for outdoor enthusiasts, commuters, and anyone needing reliable protection from rain and moisture. Understanding the materials used in their construction helps consumers make informed decisions about quality, durability, and appropriate use cases. These materials range from high-tech synthetics to treated natural fibers, each offering different benefits for various applications.

Waterproof hats are primarily made from synthetic materials like polyester and nylon with specialized waterproof coatings, natural fibers with water-repellent treatments, and innovative technical fabrics featuring laminated membranes. At AceAccessory, a core brand of shanghaifumaoclothing https://shanghaiGarment.com, our waterproof hat collections utilize advanced material technologies that undergo rigorous testing to ensure reliable performance in wet conditions while maintaining comfort, style, and breathability for our global customers.

This comprehensive guide examines the primary materials used in waterproof hat construction, exploring their properties, manufacturing processes, and appropriate applications. We'll cover coated synthetics, laminated membranes, natural fiber treatments, blended technical fabrics, and sustainable waterproof options.

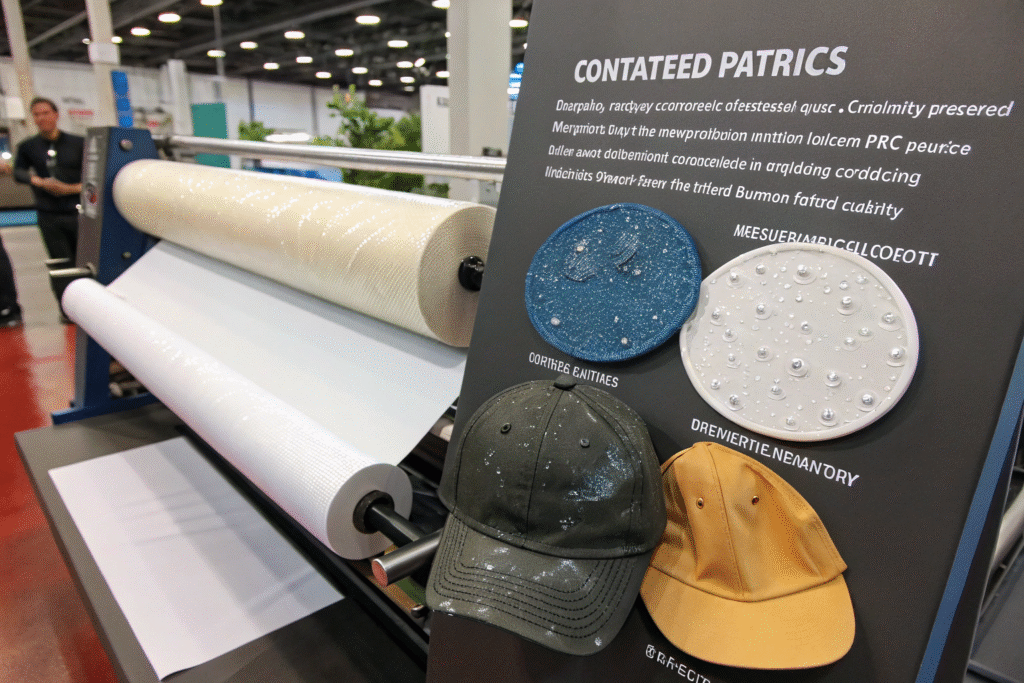

What Coated Synthetic Fabrics Dominate Waterproof Hat Production?

Coated synthetic fabrics represent the most common category of materials used in waterproof hat manufacturing, offering excellent water resistance, durability, and cost-effectiveness. These materials undergo specialized treatments that create effective barriers against moisture while maintaining the fabric's flexibility and wearability.

The dominant coated synthetics include polyurethane-coated polyester, PVC-laminated nylon, and acrylic-coated fabrics with enhanced breathability. At AceAccessory, we select coating types and weights based on the specific performance requirements of each hat style, ensuring optimal balance between waterproofing, breathability, and comfort for the intended use.

How Does Polyurethane Coating Create Effective Water Barriers?

Polyurethane coating creates effective water barriers through a continuous polymer layer that fills the fabric's inter-yarn spaces, preventing water penetration while allowing some vapor transmission. Our manufacturing process applies PU coatings in controlled thicknesses—typically 0.5-2.0 mil—depending on the required waterproof rating and flexibility needs. The resulting fabric achieves hydrostatic head ratings of 1,500-10,000 mm, making it suitable for anything from light drizzles to heavy downpours. The American Society for Testing and Materials (ASTM) provides standardized testing methods that verify these performance claims, ensuring consistent quality across production batches.

Why is Coated Nylon Preferred for High-Performance Applications?

Coated nylon is preferred for high-performance applications because of its exceptional strength-to-weight ratio, tear resistance, and durability under harsh conditions. The combination of nylon's inherent toughness with specialized coatings creates fabrics that withstand abrasion, repeated folding, and UV exposure without compromising waterproof integrity. Our technical outdoor hats utilize nylon with double-sided coatings that provide additional protection against internal condensation, making them ideal for hiking, fishing, and other activities where reliable performance is crucial regardless of weather conditions.

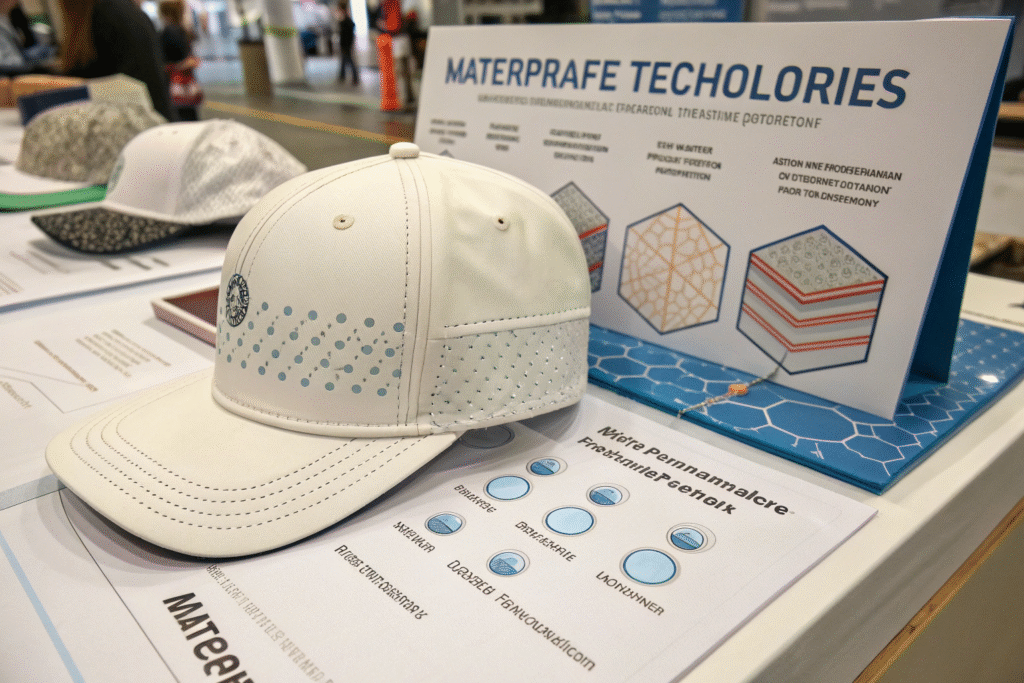

What Laminated Membrane Technologies Offer Advanced Waterproofing?

Laminated membrane technologies represent the premium segment of waterproof hat materials, incorporating microscopic porous films that block liquid water while allowing vapor to escape. These advanced materials provide superior comfort during extended wear by addressing the common issue of internal moisture buildup.

Key membrane technologies include ePTFE (expanded Polytetrafluoroethylene) like classic Gore-Tex, polyurethane membranes for enhanced flexibility, and electrospun nanofiber laminates for maximum breathability. At AceAccessory, our premium hat collections incorporate these membranes in 2-layer, 2.5-layer, or 3-layer constructions depending on the balance of protection, packability, and durability required.

How Do ePTFE Membranes Work at the Microscopic Level?

ePTFE membranes work at the microscopic level through a matrix of pores approximately 20,000 times smaller than a water droplet but 700 times larger than a water vapor molecule. This physical barrier principle prevents liquid water penetration while allowing sweat vapor to escape, maintaining comfort during physical activity. Our manufacturing partners like Gore-Tex provide certified materials and construction guidelines that ensure every hat meets strict performance standards. The result is headwear that keeps users dry from both external rain and internal perspiration, a crucial advantage for active use cases.

What Are the Benefits of 3-Layer vs 2.5-Layer Construction?

The benefits of 3-layer versus 2.5-layer construction involve trade-offs between durability, packability, and weight. Three-layer construction sandwiches the membrane between an outer fabric and an inner lining, creating the most durable option ideal for frequently worn hats. 2.5-layer construction applies a protective print directly to the membrane, reducing weight and pack size for occasional or backup headwear. Our design team selects the appropriate construction based on the hat's intended use—3-layer for everyday performance hats and 2.5-layer for compact travel or emergency rain hats where minimal weight and volume are priorities.

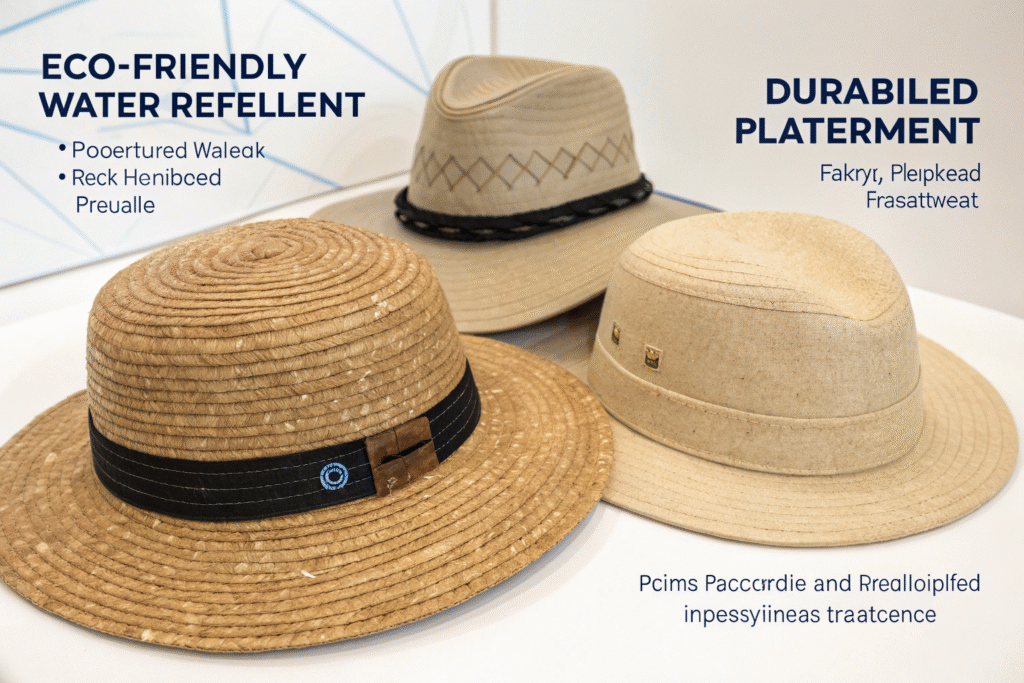

What Natural and Treated Materials Provide Eco-Friendly Waterproofing?

Natural and treated materials offer sustainable alternatives for waterproof hats, appealing to environmentally conscious consumers who prefer natural fibers over synthetics. These materials provide distinctive aesthetics and biodegradability while offering reliable water protection through traditional and modern treatment methods.

Popular natural waterproof materials include waxed cotton, oiled leather, tightly woven wool with lanolin, and plant-based treatments like beeswax and soy-based coatings. At AceAccessory, our eco-friendly collections combine these traditional materials with contemporary manufacturing techniques, creating hats with character and environmental benefits.

How Does Waxed Cotton Develop Its Water-Resistant Properties?

Waxed cotton develops its water-resistant properties through a meticulous impregnation process where paraffin-based or natural waxes are worked into the fabric fibers, causing them to swell and create a water-repellent barrier. Our traditional waxed cotton hats undergo multiple coating and curing stages that ensure even penetration and consistent performance. Unlike coated synthetics that create a continuous barrier, waxed cotton allows minimal breathability through the fabric itself while causing water to bead and run off the surface. This characteristic makes it ideal for moderate rainfall conditions where some airflow is desirable.

What Modern Treatments Enhance Natural Fiber Performance?

Modern treatments enhance natural fiber performance through eco-friendly durable water repellent (DWR) finishes, bio-based polyurethane coatings, and plasma treatments that modify fiber surfaces at the molecular level. Our advanced natural fiber hats utilize PFC-free (perfluorocarbon-free) DWR treatments that provide excellent water beading without environmental persistence. These contemporary approaches allow us to maintain the desirable hand-feel and biodegradability of natural materials while significantly improving their waterproof performance and durability compared to traditional treatments alone.Explore our eco-friendly waterproof hats: waxed cotton waterproof hats, PFC-free natural fiber waterproof hats, custom sustainable waterproof hat services.

Conclusion

Waterproof hats utilize a diverse range of materials, from high-tech synthetics with advanced coatings to traditional natural fibers with modern treatments. Understanding these material options helps consumers select headwear that matches their specific needs for protection, breathability, sustainability, and aesthetic preference. As material technologies continue to evolve, waterproof hats are becoming increasingly effective, comfortable, and environmentally responsible, offering reliable solutions for staying dry in wet conditions without compromising on style or comfort. To explore bulk pricing, download technical data sheets, or request free product samples for waterproof testing, visit shanghaiGarment.com’s waterproof hat sourcing hub.

If you're interested in sourcing or developing waterproof hats using any of these material technologies, we invite you to contact our Business Director, Elaine. She and our AceAccessory team specialize in manufacturing waterproof headwear that combines technical performance with market-appropriate styling. Reach out to Elaine at: elaine@fumaoclothing.com.