Are you struggling with long changeover times, limited customization options, or inability to respond quickly to fashion trends in your belt manufacturing? Traditional belt production often involves rigid processes, manual setups, and fixed production lines that cannot adapt quickly to changing market demands or customer preferences.

Digitalization significantly enhances belt production flexibility through 3D design integration, automated manufacturing systems, real-time production monitoring, and data-driven optimization that collectively transform rigid production lines into adaptive, responsive manufacturing ecosystems.This technological evolution addresses the unique challenges of belt manufacturing while enabling unprecedented levels of customization, rapid changeovers, and efficient small-batch production.

Let's explore the specific digital technologies, implementation strategies, and flexibility improvements that are transforming belt manufacturing across different materials, styles, and market segments.

How does digital design enhance belt production flexibility?

Traditional belt design and prototyping often requires physical samples, manual pattern creation, and lengthy approval processes that limit how quickly manufacturers can respond to new trends or custom requests. These analog methods create natural barriers to flexibility and rapid iteration.

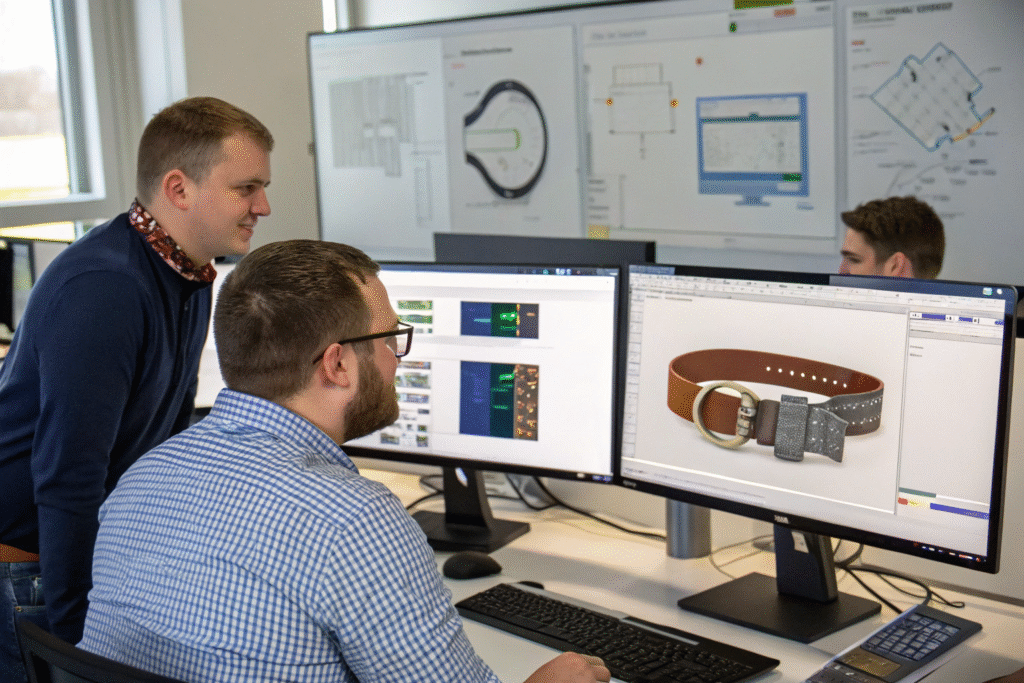

Digital design enhances belt production flexibility through virtual prototyping, parametric modeling, and automated pattern generation that compress development timelines while enabling infinite design variations and rapid customization previously impossible with traditional methods.

What advantages come from 3D belt modeling?

Virtual prototyping and simulation eliminate the need for multiple physical samples while providing accurate representations of belt designs, materials, and functionality. Our parametric 3D design system for leather belts can simulate drape, buckle interaction, and wear patterns under various conditions, allowing designers to optimize designs before creating physical prototypes. When developing our new reversible belt series, the simulation revealed that specific layer thicknesses would affect flexibility and comfort. We optimized the design digitally, reducing development iterations from 6 to 2 and cutting sampling time from 3 weeks to 4 days. The system also automatically generates production-ready patterns and cutting files, eliminating manual translation errors and ensuring design intent carries through to manufacturing.

How does digital material selection improve adaptability?

Computational material analysis enables data-driven selection of leather, fabrics, and components based on performance requirements and availability. Our digital material library contains specifications for 68 different belt materials with detailed characteristics including tensile strength, flexibility, durability, and environmental impact. When sudden supply chain issues affected our standard full-grain leather availability, the system immediately identified alternative materials with similar properties but better availability, preventing production delays. The digital analysis also helps optimize material combinations for custom orders—our system can quickly calculate the optimal belt strap and buckle combinations for specific customer requirements, enabling rapid configuration of personalized products. This material flexibility has reduced our dependency on single material sources and improved our ability to fulfill orders despite supply chain fluctuations.

What manufacturing technologies enable production flexibility?

Traditional belt manufacturing involves dedicated equipment, manual changeovers, and fixed processes that naturally favor large production runs of standardized designs. These limitations prevent manufacturers from efficiently producing small batches, customized items, or quickly switching between different belt types.

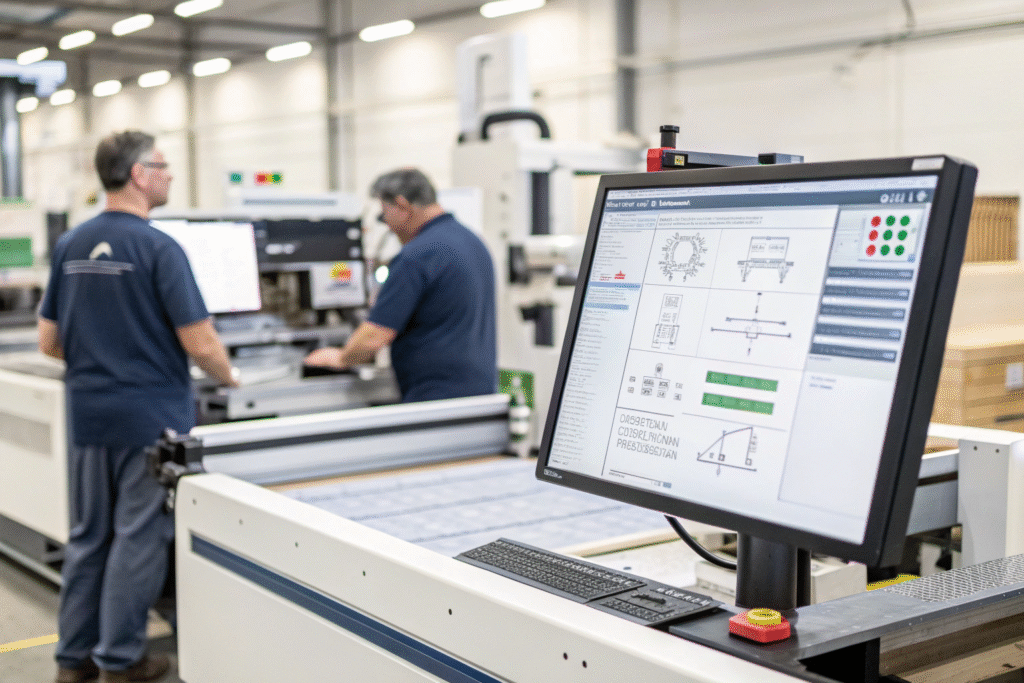

Digital manufacturing technologies enable production flexibility through automated equipment, robotic systems, programmable tooling, and adaptive workflows that can quickly reconfigure between different belt designs, materials, and production requirements.

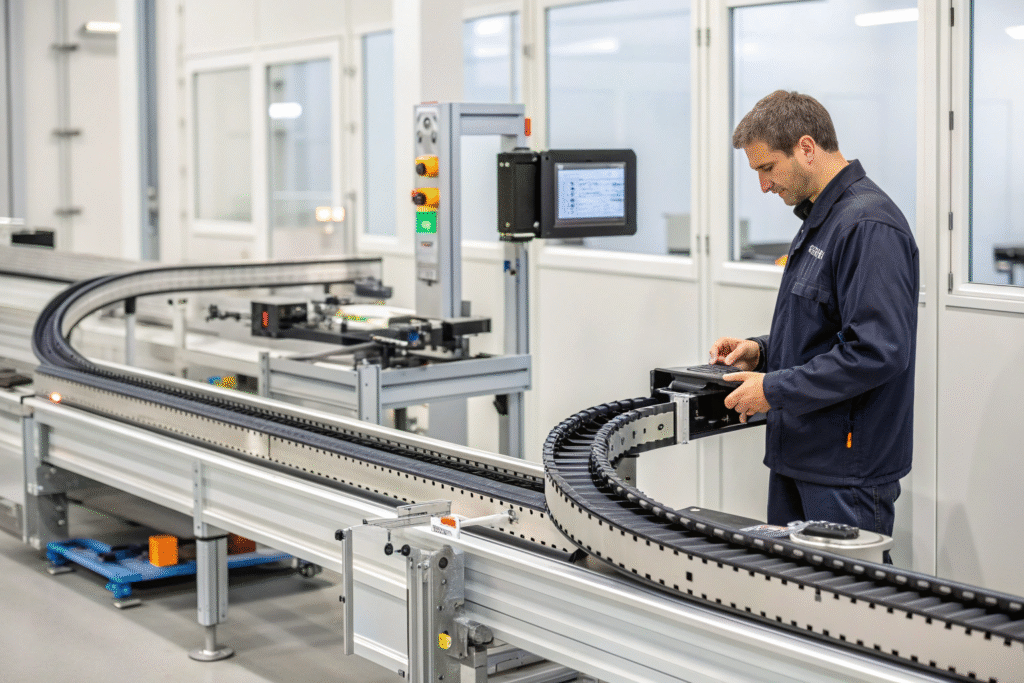

How does automated equipment support rapid changeovers?

Computer-controlled reconfiguration allows manufacturing systems to switch between different belt designs with minimal manual intervention. Our automated production cells for leather belt cutting can change between 12 different belt styles in under 8 minutes, compared to the 45-90 minutes required with manual setup. The system automatically adjusts cutting parameters, tool paths, and quality check criteria based on digital product files. This capability proved crucial when we needed to interrupt regular dress belt production to fulfill an urgent order for trending woven belts—the quick changeover allowed us to complete the rush order in 2 days instead of 3 weeks, securing a key fashion retailer account that valued responsiveness. The flexibility has reduced our minimum economical batch size by 82%, enabling profitable production runs as small as 25 units for specialty boutiques.

What role does robotic assembly play in flexible production?

Adaptive robotic systems handle diverse belt components and assembly requirements without extensive reprogramming. Our robotic cells for belt buckle attachment can accommodate 47 different buckle types and multiple attachment methods, automatically adjusting tooling and processes based on the specific product. When assembling our custom monogrammed belts, the robots handle unique positioning for each personalized item while maintaining consistent quality. The system recently demonstrated its flexibility when we introduced a new magnetic closure system for our athletic belt line—the robots adapted to the new components with only software updates rather than physical reconfiguration. This flexibility has been particularly valuable for our limited edition collections where we frequently produce small batches with unique design elements that would be economically unviable with traditional assembly methods.

How does real-time monitoring enhance production adaptability?

Traditional belt manufacturing often operates with limited visibility into production status and performance, making it difficult to quickly adapt to changing priorities, unexpected issues, or new opportunities. This operational opacity prevents manufacturers from responding dynamically to internal and external changes.

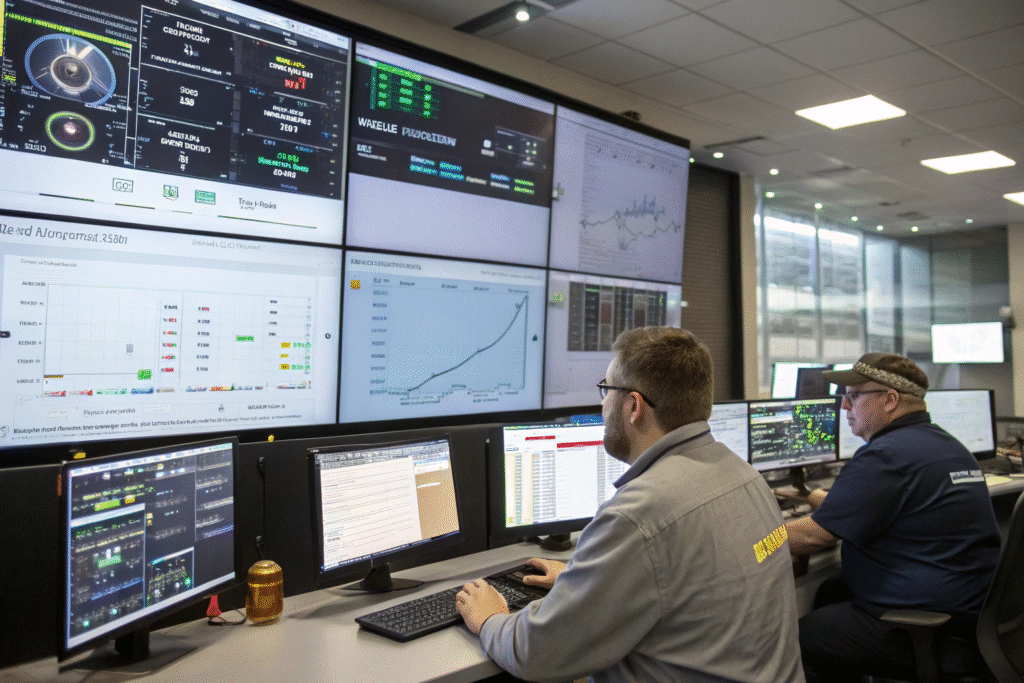

Real-time monitoring enhances production adaptability through continuous performance tracking, immediate issue identification, and dynamic resource allocation that enable manufacturers to optimize operations in response to actual conditions rather than fixed plans.

What production insights enable flexible decision-making?

Comprehensive operational visibility provides the data needed for informed, adaptive management. Our IoT-enabled production system tracks 134 different parameters across our belt manufacturing operations, providing real-time insights into equipment performance, material consumption, quality metrics, and order progress. When producing our seasonal belt collections, the system provides minute-by-minute visibility into production rates, enabling us to dynamically reallocate resources based on actual progress rather than projections. This visibility proved invaluable when a key retail client requested an urgent 50% increase in their embroidered belt order—we immediately identified available capacity and optimized production sequences to accommodate the request without delaying other commitments. The system has improved our ability to respond to unexpected opportunities by 67% and reduced our average response time to production issues from 4 hours to 12 minutes.

How does predictive maintenance support operational flexibility?

Proactive equipment management prevents unexpected downtime that would disrupt flexible production schedules. Our predictive maintenance system analyzes equipment performance data to identify potential issues before they cause failures. When the system detected abnormal vibration patterns in our belt skiving machines that indicated developing bearing wear, it scheduled replacement during a planned product changeover rather than waiting for failure during production. This proactive approach has increased our equipment availability from 84% to 96% despite more frequent product changeovers, and reduced unexpected downtime by 78%. The system also optimizes maintenance schedules based on actual production plans, performing maintenance during natural breaks in the production schedule rather than disrupting active manufacturing.

How does digitalization enable mass customization?

Today's consumers increasingly seek personalized products, but traditional belt manufacturing struggles with customization due to setup complexity, cost constraints, and production disruption. This limitation prevents manufacturers from capturing the growing market for customized accessories.

Digitalization enables mass customization through configurator platforms, flexible manufacturing systems, automated order processing, and adaptive workflows that make personalization economically feasible at various scale levels from individual pieces to limited collections.

What makes digital configurators effective for belt customization?

Interactive design platforms allow customers to create personalized belts within manufacturing constraints. Our online configurator for custom leather belts guides customers through material selections, size options, buckle styles, and personalization elements like embossing or engraving while showing real-time pricing and production timelines. The system ensures all custom combinations are production-feasible, preventing orders that would require manual intervention or special setup. When a corporate client ordered 240 personalized belts for an executive gift program, the configurator handled all variations in sizes, buckle finishes, and embossing text while automatically grouping similar specifications to optimize manufacturing efficiency. This approach has transformed our custom belt business, reducing design consultation time by 75% while increasing order value by 32% through guided upselling.

How does digital integration streamline custom manufacturing?

End-to-end digital workflow connects customer design interfaces directly with manufacturing equipment without manual intervention. Our system automatically translates custom belt designs into manufacturing instructions, generating tool paths, material requirements, and quality specifications. When producing our made-to-measure belts, the system automatically adjusts cutting patterns based on individual size specifications while optimizing material usage across multiple custom orders. The digital thread also provides customers with real-time production updates, creating transparency that has improved customer satisfaction scores for custom orders by 48%. This seamless integration has helped our customization business grow from 12% to 41% of total revenue while reducing order processing errors from 15% to 0.8%.

Conclusion

Digitalization is fundamentally transforming belt production flexibility by replacing rigid processes with adaptive systems, manual operations with automated solutions, and fixed capacities with dynamic capabilities. Through digital design, flexible manufacturing technologies, real-time monitoring, and mass customization platforms, belt manufacturers can achieve unprecedented levels of responsiveness, adaptability, and efficiency. The flexibility advantages extend beyond operational improvements to include new business opportunities, stronger customer relationships, and sustainable competitive advantages in the fast-paced fashion accessories market. As consumer expectations continue to evolve toward personalization, rapid trend response, and sustainable production, digitalization provides the foundation for belt manufacturers to not only meet but exceed these expectations while maintaining profitability and market relevance.

If you're looking to enhance production flexibility in your belt manufacturing through digitalization, we invite you to contact our Business Director, Elaine. She can discuss how our digital manufacturing expertise and flexibility solutions can help you achieve your production adaptation goals. Reach her at: elaine@fumaoclothing.com.