As a buyer for supermarkets or fashion brands, you know that hair ties are a high-turnover item, but returns and complaints about products that quickly lose their stretch can damage your store's reputation for quality. Customers expect these small accessories to withstand repeated use and washing. So, which hair ties truly maintain their elasticity over time, and what should you look for when sourcing them? The answer lies not in a single magic brand, but in understanding the key materials, construction techniques, and quality assurances that guarantee durability.

Hair ties that maintain elasticity after multiple washes are typically made from high-quality nylon and elastane blends, feature seamless or coated construction, and come from manufacturers with rigorous quality control. The most reliable products avoid pure cotton or cheap rubber, which degrade quickly, and instead use engineered fibers designed for resilience.

Finding a supplier that provides consistent, wash-tested products is crucial for your business. Let’s delve into the specific features that define a long-lasting hair tie and how to verify them with a manufacturer.

What Materials and Construction Ensure Long-Lasting Elasticity?

The journey to a durable hair tie begins at the molecular level with its material composition and how it’s put together. Common, low-cost ties use latex rubber or cotton-covered elastic that breaks down with exposure to water, heat, and oils.

Superior hair ties use synthetic blends engineered for recovery. A common and excellent blend is 80% Nylon and 20% Elastane (Spandex). The nylon provides strength and abrasion resistance, while the elastane gives the stretch and memory to return to its original shape. Another advanced option is thermoplastic elastomers (TPE), which offer high resilience and are often used in seamless, coil-style ties.

Construction is equally important. Seamless, knit-in-the-round designs (like those from Jollybows or VOBIYCOT) eliminate weak points where threads can snap. Specialized coatings, such as the smooth polymer on Kitsch's No-Snag Elastics, protect the core elastic from friction and hair snagging, dramatically extending its life.

Why Do Seamless and Coated Designs Outlast Others?

A seam or a stitch is a failure point. Every time a traditional hair tie is stretched, the sewn join undergoes stress. After multiple washes, the thread weakens and eventually breaks. A seamless, continuously knitted tie distributes tension evenly across its entire structure, making it far more resistant to wear.

The no-snag coating serves a dual purpose. First, it allows the tie to slide out of hair effortlessly, preventing the tugging and pulling that strains the elastic. Second, it creates a protective barrier between the elastic core and water, shampoo, and heat during washing. This is why products making this claim often perform well in longevity tests. For bulk buyers, specifying these construction features to a manufacturer like shanghaifumaoclothing is the first step to securing a superior product.

How Do Material Blends Affect Wash Performance?

Pure rubber (latex) elastics are highly stretchy but prone to drying out, cracking, and breaking when exposed to the elements. Cotton covers absorb water and hold onto shampoo residues, which can degrade the inner elastic over time.

The nylon-elastane blend is the workhorse of durable accessories. Nylon is known for its toughness and excellent wash fastness. Elastane provides the stretch but is vulnerable when exposed alone; the nylon shields it. When sourcing, asking for a specification sheet with this blend ratio is a strong indicator of quality. This material science is fundamental to producing reliable fast-moving consumer goods (FMCG) for the beauty aisle.

How Can You Verify Durability as a Bulk Buyer?

For a supermarket or brand, placing an order for 10,000 units based on a glossy sample is risky. You need tangible, objective methods to verify a manufacturer's claims before committing. The process must move beyond marketing and into measurable quality assurance.

Verification requires a two-pronged approach: lab testing and real-world trial. You should request standardized test reports from the supplier and conduct your own in-house stress tests on pre-production samples. This due diligence protects your inventory investment and brand reputation.

Implementing a simple yet effective evaluation protocol is key. Here is a practical framework to follow.

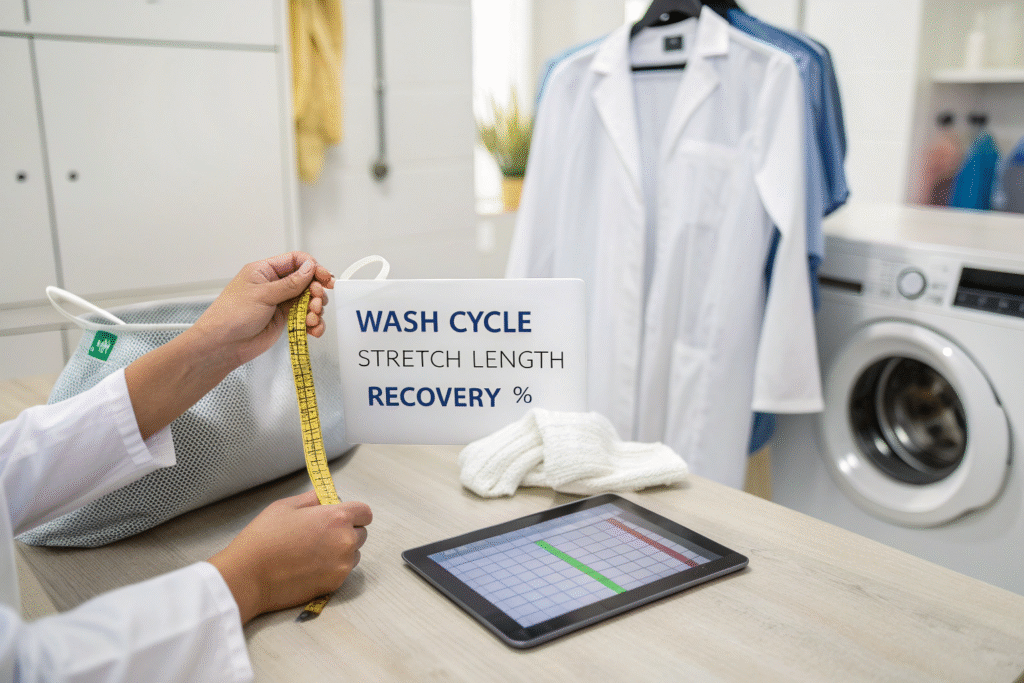

What Kind of Wash Test Report Should You Request?

A reputable manufacturer should be able to provide a Product Quality Test Report. Key sections to look for include:

- Wash Fastness Test: Data showing how the product withstands a standard number of wash cycles (e.g., 5, 10, 20 cycles) at a specified temperature.

- Elongation at Break & Recovery Rate: This is the critical metric. It measures how much the tie can stretch before breaking and, more importantly, what percentage it returns to its original length after stretching. A high recovery rate (e.g., >90% after multiple washes) indicates excellent elasticity retention.

- Color Fastness: Ensures the dye won't bleed during washing, which is also a sign of good material treatment.

If a supplier cannot provide such reports, it raises a red flag about their quality control processes. Factories with their own in-house QC teams, like AceAccessory, typically have this data on hand and can customize testing to your requirements.

How Can You Conduct a Simple, Effective In-House Test?

While waiting for official reports, you can run a convincing pilot test with samples:

- The Laundry Cycle Test: Place a sample of hair ties in a small mesh bag. Run them through repeated washing and drying cycles (both machine and air-drying) alongside a typical load of laundry. After every 3-5 cycles, manually test their stretch.

- The Stretch-and-Hold Test: Repeatedly stretch the ties to their maximum comfortable diameter (simulating going over a hand or ponytail) and hold for 10 seconds. Observe if they slowly become looser or consistently snap back. A good tie should recover instantly.

- The Real-User Trial: Distribute samples to staff or a small focus group for everyday use and washing over a few weeks. Gather feedback on breakage and loss of grip.

This hands-on approach will quickly separate promising products from poor ones and give you concrete data to discuss with your supplier.

Which Product Types Are Known for Durability?

Based on market availability and user feedback, certain designs have built a reputation for longevity. When building your product assortment, prioritizing these types can reduce customer complaints.

The current standouts are seamless coil elastics, thick no-snag elastics, and high-quality scrunchies with a durable core. These designs inherently address the common failure points of traditional ties.

Here’s a breakdown of these reliable types and what makes them special.

What Makes Seamless Coil Elastics a Top Performer?

Products like the Jollybows Elastic Hair Ties or similar unbranded coil ties are a benchmark for durability. Their continuous, spring-like coil structure (usually made from TPE or nylon) has no beginning or end, making it virtually impossible to fray. They are lightweight, dry quickly, and their elasticity comes from the geometry of the coil itself, which is highly resilient.

For bulk sourcing, these are excellent candidates. They are often sold in large counts (e.g., 300-piece packs) for a low unit cost, making them perfect for volume-driven retail environments like supermarkets. Their simple, functional design appeals to a broad audience seeking a no-fuss, reliable product.

Why Are "No-Snag" and Quality Scrunchies Reliable?

The Kitsch No-Snag Elastics exemplify the coated approach. The slick coating not only protects the hair and the tie but also makes the elastic core less susceptible to damage from water and chemicals. This engineering focus directly translates to a longer usable life.

A well-made scrunchie is often durable because its outer fabric (velvet, silk, etc.) shields the inner elastic band from direct exposure and stress. The key is the quality of that inner band. A thick, covered elastic core made from a good nylon-elastane blend will last much longer than a thin, exposed rubber band sewn inside. When sourcing scrunchies, inquiring about the specification of the inner band is essential.

Conclusion

Sourcing hair ties that maintain elasticity after multiple washes is a matter of focusing on material science and verifiable quality. By prioritizing seamless nylon/elastane blends or coated constructions, and by insisting on wash test reports and conducting your own trials, you can secure a product that satisfies customers and minimizes returns.

For buyers looking to source such durable hair accessories in bulk with consistent quality, partnering with a manufacturer that controls the entire production and testing process is the most efficient path. At AceAccessory, our in-house design and QC teams can produce hair ties to your exact durability specifications, from material selection to final wash testing. To discuss developing a long-lasting hair tie line for your stores, please contact our Business Director, Elaine, at elaine@fumaoclothing.com for a professional consultation and quote.