When I work with international buyers, I hear one pain point again and again: long lead times. For brands and retailers in the U.S. and Europe, waiting too long for products can mean missing out on seasonal sales or losing competitive advantage. The pressure is always there to keep the supply chain moving fast while still ensuring product quality.

Reducing lead times for custom accessories is possible by optimizing production planning, using advanced sampling methods, and partnering with experienced suppliers who can guarantee both speed and quality.

That is why, as a manufacturer, I spend much of my time refining every part of our process—from design and sampling to production and logistics. I know that clients like Ron, a confident buyer in America, care about quick turnaround as much as they care about product quality. By focusing on both, we can build long-term trust.

How Can Efficient Sampling Speed Up Delivery?

Delays often begin at the sampling stage. When a client requests custom designs, the longer it takes to finalize a sample, the more overall production time gets pushed back. Many factories still use old methods that require weeks for revisions. That creates frustration for buyers.

Efficient sampling speeds up delivery because digital design tools, 3D mock-ups, and in-house sample rooms allow for faster approvals and fewer errors.

Today, we use both digital CAD design and physical prototyping. With these tools, clients can see near-final products in days instead of weeks. Quick feedback cycles reduce mistakes later in mass production. This method is especially helpful for buyers who need to present products quickly for upcoming fashion seasons.

Why Should Buyers Ask About Digital Sampling?

Digital sampling allows brands to see detailed renderings before physical samples are even made. This saves both time and costs. Many suppliers now integrate tools similar to CLO 3D that give buyers a clear preview of shape, texture, and fit. Combined with modern fabric simulation, it makes decision-making easier. Some buyers even integrate samples into their online stores early, creating buzz before production finishes.

How Do In-House Sample Rooms Make a Difference?

Factories that maintain their own sample rooms avoid dependency on third parties. For example, our Zhejiang facility includes a specialized sampling line for hair accessories, hats, and scarves. That means if a buyer requests a new hat prototype, we can develop it in days without relying on external vendors. This independence improves control and consistency.

What Role Does Supply Chain Optimization Play?

Once samples are approved, production and delivery depend heavily on supply chain efficiency. Many buyers underestimate how much time can be lost in transit and customs. A strong logistics plan reduces unnecessary delays.

Optimizing the supply chain helps reduce lead times through better vendor management, faster shipping options, and reliable customs clearance processes.

As a factory, we not only produce but also manage logistics for many of our clients. This means we coordinate container bookings, shipping routes, and tariff solutions. By handling the process directly, we ensure products arrive on time.

How Can Logistics Partners Impact Lead Time?

Working with the right logistics partner can cut weeks from shipping. Companies such as DHL Global Forwarding and Maersk offer consolidated services that reduce bottlenecks. Many buyers now also prefer hybrid transport—combining air and sea freight to balance speed and cost. By partnering with reliable freight forwarders, brands avoid the risks of last-minute vessel changes.

Why Is Customs Clearance a Critical Factor?

Even after shipping, goods can get stuck at customs. Experienced suppliers know how to prepare documents, including certificates of origin and compliance reports, to avoid delays. For example, following U.S. CBP import regulations ensures smoother entry into the American market. Many of our clients choose us specifically because we help navigate tariff exemptions and duty reductions, which further speeds up the process.

Can Production Planning Reduce Delays?

Inside the factory, poor planning is one of the biggest causes of long lead times. Even when samples are approved quickly, production can slow down if schedules are not managed correctly.

Better production planning reduces delays because it balances capacity, forecasts demand, and allocates resources efficiently.

We rely on both software and human oversight to plan orders. This ensures each client’s project runs smoothly and avoids conflicts with peak seasons.

How Does Capacity Forecasting Improve Timelines?

Factories that forecast demand well can keep raw materials in stock. By using systems like SAP ERP, manufacturers can predict busy seasons and prepare accordingly. This reduces waiting time for fabric, trims, and packaging. Buyers benefit because their orders do not get delayed due to shortages.

Why Is Skilled Project Management Essential?

Even with software, human project managers remain vital. At our company, each client has a dedicated manager who follows every detail—from sample approval to shipping. This system ensures problems are solved quickly. For example, if a batch of scarves faces a minor quality issue, managers act immediately to fix it without delaying the full shipment.

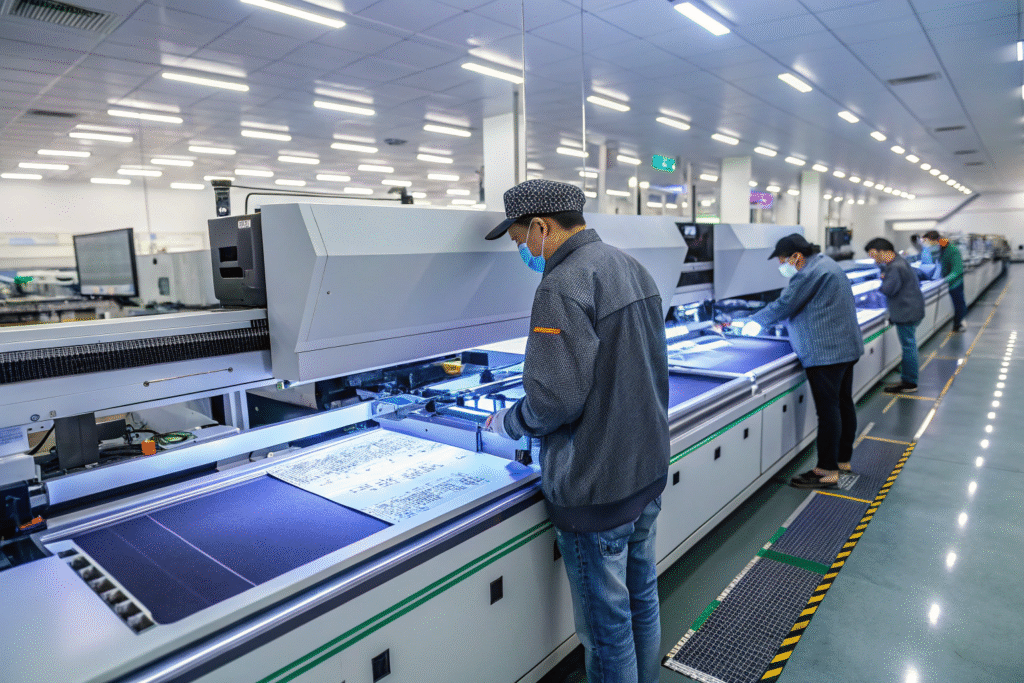

Are Technology and Automation Key to Faster Turnaround?

Finally, technology plays a decisive role in reducing lead times. Many factories still depend on manual methods that cannot keep up with global demand.

Technology and automation shorten lead times by streamlining repetitive tasks, improving precision, and reducing errors.

Automation does not replace workers but supports them to work faster and better.

What Are the Benefits of Automated Cutting and Sewing?

Automated machines can cut and sew fabrics with greater accuracy. For example, Gerber Technology provides solutions that reduce fabric waste and improve consistency. Buyers see faster turnaround times because large batches can be produced without constant manual adjustments.

How Does Digital Quality Control Improve Speed?

Using AI-driven quality control cameras, factories can detect defects early. Tools like Qualitas are already in use in textile and accessory industries. Instead of waiting until the final inspection, problems are spotted during production. This reduces rework and accelerates shipment. Buyers benefit because fewer surprises occur after goods are packed.

Conclusion

Reducing lead times for custom accessories requires a complete approach—from digital sampling and supply chain optimization to production planning and automation. Buyers who partner with experienced factories like ours enjoy faster development, reliable delivery, and consistent quality.

At AceAccessory, we specialize in helping international clients shorten timelines without sacrificing craftsmanship. If you are planning to produce accessories like hats, scarves, or belts, contact our Business Director Elaine at elaine@fumaoclothing.com to explore how we can bring your ideas to market quickly and efficiently.