As a forward-thinking buyer like Ron, you're not just focused on the final product; you're interested in the process. You know that the technology behind the product dictates its quality, cost, and creative potential. When it comes to knitted hats, you might have an image of traditional, clunky machines. But the industry has undergone a quiet revolution. You need to know what's happening on the factory floor and how the latest machinery innovations can give your brand a competitive edge.

The latest and most significant innovation in knitted hat machinery is the widespread adoption of fully computerized, seamless "whole-garment" knitting technology. These advanced machines can knit a complete, three-dimensional beanie from yarn to finished product in a single, continuous process, eliminating the need for manual cutting and sewing. This leap in technology offers unprecedented design freedom, superior quality, and a dramatic increase in production efficiency.

I get genuinely excited when I talk about this because it has fundamentally changed what we can offer our clients. At Shanghai Fumao Clothing, we have invested heavily in these state-of-the-art machines. They are the engine behind our ability to produce higher quality, more complex, and more sustainable knitwear than ever before. Let's dive into how this technology works and what it means for your business.

What Is "Whole-Garment" Knitting Technology?

To understand the innovation, you first have to understand the old way. Traditionally, knitted hats were made like t-shirts: a machine would knit a large, flat piece of fabric, which would then be cut into pattern pieces and sewn together by workers. This process was time-consuming and created a weak point: the seam.

"Whole-garment" knitting is a revolutionary process where a computerized machine knits a hat in three dimensions, directly from a digital file, creating a finished product with no seams. The machine's needle beds are controlled by sophisticated software that can shape the crown, create the fold, and finish the edge all in one go. It's essentially 3D printing with yarn.

This technology, pioneered by companies like Shima Seiki with their WHOLEGARMENT® machines and Stoll with their "knit and wear" technology, is the new gold standard in knitwear production. For us, it means we can produce a perfectly shaped beanie in minutes, a task that used to involve multiple steps and multiple workers. This leap in efficiency and quality is what allows us to create superior products.

How does the machine work?

The machine has multiple needle beds and advanced computer controls that allow it to transfer stitches, add or reduce needles, and shape the fabric in three dimensions as it knits. A designer creates a 3D data file for the hat, which is then loaded into the machine. The machine reads the file and executes the knitting process automatically, producing a complete hat that drops from the machine ready for a final wash and finish.

Is it really "zero waste"?

Yes, for the most part. Because the hat is knitted to its exact shape, there is no cutting of fabric panels, which traditionally results in 15-20% of the yarn being wasted as scrap. This makes it a far more sustainable manufacturing method, a powerful story for any brand with an eco-conscious customer base. This is a major topic in sustainable fashion resources like the Council of Fashion Designers of America (CFDA).

How Does This Technology Improve Product Quality?

Efficiency is great for us as a manufacturer, but what does this new technology mean for you and your customer in terms of the final product?

This technology dramatically improves product quality by creating a seamless construction that offers a superior fit, enhanced comfort, and a cleaner, more premium aesthetic. Seams are rigid, can be itchy, and create a point of structural weakness. A seamless hat, by contrast, has a continuous, uninterrupted stretch that conforms perfectly to the wearer's head.

Think about a high-performance athletic sock versus a cheap tube sock. The difference is in the anatomical, seamless fit. We are now bringing that same level of sophistication to knitted hats. The drape is better, the stretch is more uniform, and the overall look and feel is far more luxurious. This superior quality is what opens the door to unprecedented design possibilities.

What are the key quality benefits?

- Superior Comfort: No bulky or itchy seams to irritate the skin.

- Better Fit: The 3D construction and uniform stretch allow the hat to fit a wider range of head sizes more comfortably.

- Increased Durability: Eliminating the seam removes the most common point of failure where a hat can unravel.

- Clean Aesthetics: The knit pattern flows beautifully and uninterrupted around the entire hat, which looks much more high-end.

What New Design Possibilities Does It Unlock?

Perhaps the most exciting aspect of this technology is the creative freedom it unleashes. We are no longer limited by the constraints of cutting and sewing flat fabric.

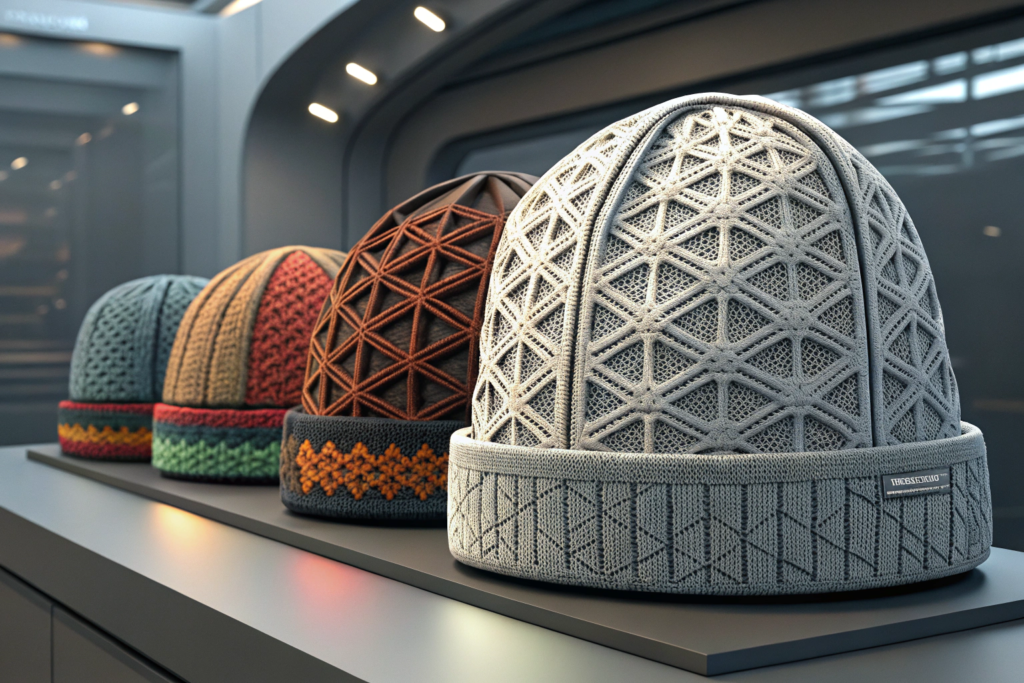

Computerized whole-garment knitting unlocks unprecedented design possibilities, allowing for intricate 3D textures, seamless multi-color jacquard patterns, and the integration of different knit structures (like rib and cable) within a single, continuous piece. If a designer can create it in a 3D program, we can likely knit it.

This is where we can truly partner with creative brands. Do you want a beanie with a structural, architectural rib that flows seamlessly into a smooth crown? We can do that. Do you want a complex, pixel-art-style graphic that wraps perfectly around the hat with no mismatched seam? We can do that. We can even knit in functional elements, like a double-layered band for extra warmth over the ears. This technology transforms the humble beanie into a canvas for high-tech design, a key factor in determining the future of knitwear.

What specific designs are now possible?

- 3D Textures: Creating bumps, ridges, and structural patterns that are integral to the fabric itself.

- Seamless Jacquard: Knitting intricate, multi-color patterns (like Fair Isle or complex logos) that are perfectly aligned.

- Zonal Knitting: Changing the knit structure in different zones of the hat, for example, a breathable, open-knit on top and a tight rib on the cuff.

- Anatomical Shaping: Creating hats that are ergonomically shaped for a perfect, helmet-like fit, ideal for performance and athletic wear.

Design and technology publications like Dezeen often feature projects that explore the cutting edge of digital knitting technology.

What Is the Future of Knitwear Manufacturing?

This technology is more than just a new machine; it represents a fundamental shift in how the entire knitwear industry operates. What does the future look like?

The future of knitwear manufacturing is digital, on-demand, and sustainable, with whole-garment technology at its core. This innovation allows for a fully digitized workflow, from a 3D design file straight to a finished product. This dramatically speeds up the development process and opens the door to new business models like small-batch production and even localized, on-demand manufacturing.

At Shanghai Fumao Clothing, we are already living this future. Our clients can send us a digital file, and we can produce a perfect, seamless sample in a matter of hours, not weeks. For a new brand, this means they can test a design with a small production run of just a few hundred pieces. For a large brand, it means we can produce their massive orders with unparalleled speed, consistency, and quality. This technology is the key to a more agile, responsive, and sustainable supply chain.

What does this mean for speed to market?

The time from design finalization to finished sample can be reduced by over 80%. What used to take weeks of programming, knitting flat panels, and sewing samples can now be done in a day. This allows brands to react to trends almost in real-time.

How does it enable "mass customization"?

Because each machine is controlled by a digital file, it's possible to make small changes to a design without significant setup costs. A brand could theoretically offer a hat in the same style but with a dozen different personalized logos or patterns, each produced in small, efficient batches. This is a key topic in discussions about the future of retail, often called "Manufacturing 4.0."

Conclusion

The world of knitted hat production has evolved far beyond the simple machines of the past. The rise of computerized, seamless whole-garment technology represents a quantum leap forward, offering unmatched quality and comfort, unlocking vast creative possibilities, and paving the way for a more efficient and sustainable future. For a brand looking to create a truly superior knitwear program, partnering with a manufacturer who has mastered this technology is no longer just an advantage; it is an absolute necessity.

At Shanghai Fumao Clothing, we have placed ourselves at the forefront of this technological revolution. Our investment in the latest machinery is a direct investment in our clients' success, allowing us to produce the highest quality, most innovative knitted hats on the market.

If you are ready to leverage the future of knitwear technology for your brand, let's talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to discover what we can create together.