The creation of fashionable accessories has evolved dramatically with technological advancements, blending traditional craftsmanship with cutting-edge innovations. At AceAccessory, we've integrated multiple technologies that have transformed how we design, produce, and customize accessories for global markets.

The key technologies in creating fashionable accessories include 3D design and prototyping, advanced materials science, automated manufacturing systems, smart technology integration, and sustainable production methods. These technologies work together to enhance creativity, efficiency, quality, and customization capabilities while addressing environmental concerns.

The intersection of technology and fashion has opened new possibilities for accessory creation that were unimaginable just a decade ago. Let's explore the specific technologies shaping the future of fashionable accessories.

How has digital design technology transformed accessory creation?

Digital design tools have revolutionized the conceptualization and development process, enabling greater creativity, precision, and efficiency in accessory design.

Digital design technology encompasses 3D modeling software, virtual prototyping, augmented reality visualization, and AI-assisted design that collectively accelerate development while improving design quality and customization possibilities.

What 3D modeling capabilities enhance accessory design?

Advanced CAD and modeling software provide unprecedented design control and visualization. Key technologies include:

- Parametric modeling allowing designers to create adaptive designs that automatically adjust to changes in dimensions or components

- Realistic material rendering showing exactly how different materials, finishes, and colors will appear in final products

- Virtual wear testing simulating how accessories will look and function when actually worn

- Assembly simulation identifying potential manufacturing issues before physical prototyping

Our adoption of advanced 3D modeling has reduced design iteration time by 65% and improved first-sample success rates from 45% to 88%. Designers can now explore more creative options with confidence that their visions can be successfully translated into physical products.

How does AI contribute to accessory design?

Artificial intelligence systems augment human creativity with data-driven insights. We utilize:

- Generative design algorithms that create numerous design variations based on specified parameters and constraints

- Trend forecasting AI that analyzes social media, runway shows, and sales data to predict successful design elements

- Material optimization systems that suggest ideal material combinations based on aesthetic goals and performance requirements

- Style analysis tools that ensure new designs align with brand identity and market preferences

The table below shows how AI technologies impact different aspects of accessory design:

| AI Technology | Design Application | Impact |

|---|---|---|

| Generative Design | Creating multiple design variations | 5x more design options explored |

| Trend Prediction | Identifying successful style elements | 42% higher commercial success rate |

| Material Recommendation | Optimizing material selection | 35% reduction in material-related revisions |

| Proportion Analysis | Ensuring visual balance | 28% faster achievement of design harmony |

These AI integrations have transformed our design process from intuition-based to data-informed while preserving creative vision.

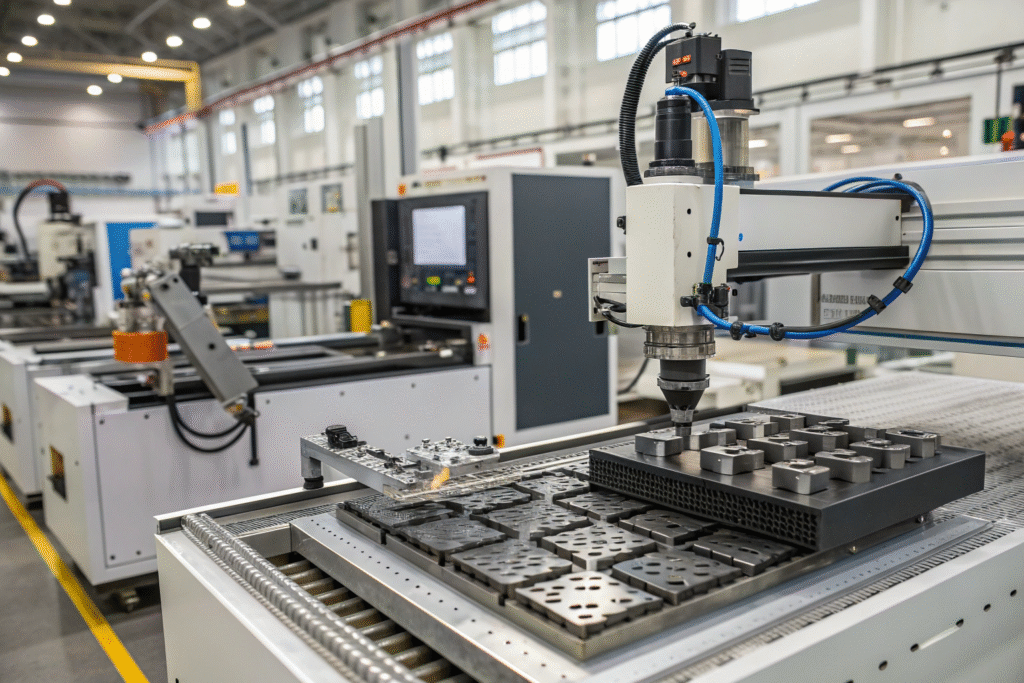

What manufacturing technologies are revolutionizing accessory production?

Modern manufacturing technologies have dramatically improved the precision, efficiency, and capabilities of accessory production across all categories.

Advanced manufacturing technologies include computer-controlled fabrication, additive manufacturing, robotic assembly, and precision finishing systems that enable higher quality and greater production flexibility.

How has automation transformed accessory manufacturing?

Computer-controlled production systems deliver unprecedented consistency and efficiency. Key technologies include:

- CNC machining for precise cutting, carving, and shaping of metal, wood, and plastic components

- Laser cutting and engraving enabling intricate patterns and personalized details on various materials

- Robotic assembly ensuring consistent quality in complex assembly processes

- Automated quality control using computer vision to detect imperfections invisible to the human eye

Our implementation of automated systems has increased production capacity by 300% while reducing error rates by 78%. The consistency achieved through automation has been particularly valuable for creating accessories with precise details and perfect symmetry.

What role does 3D printing play in accessory production?

Additive manufacturing enables new design possibilities and production approaches. We utilize:

- Multi-material 3D printing creating accessories with varying material properties in single production runs

- High-resolution printing producing jewelry and small accessories with intricate details

- Rapid prototyping accelerating design validation and reducing time to market

- Customized production enabling cost-effective manufacturing of personalized and limited-edition pieces

3D printing has been revolutionary for creating complex geometric designs and organic forms that would be difficult or impossible to produce with traditional manufacturing methods. We've successfully integrated 3D-printed components with traditionally crafted elements to create hybrid accessories that blend technological innovation with artisanal quality.

What smart technologies are being integrated into accessories?

The convergence of fashion and technology has created new categories of smart accessories that offer functionality beyond traditional aesthetic purposes.

Smart technologies in accessories include connectivity features, sensory capabilities, interactive elements, and adaptive functionalities that enhance both utility and user experience.

How are connectivity technologies enhancing accessories?

Integrated electronics transform accessories into connected devices. Current implementations include:

- Bluetooth connectivity enabling accessories to communicate with smartphones and other devices

- NFC chips allowing authentication, information sharing, and touchless interactions

- GPS tracking providing security and location services for valuable items

- Wireless charging eliminating the need for visible ports or cables

We've developed smart handbags with integrated tracking and charging capabilities, jewelry that delivers discreet notifications, and belts with posture monitoring. These connected accessories maintain their fashion appeal while offering practical benefits that justify their technological integration.

What sensory technologies are appearing in accessories?

Interactive and responsive features create dynamic user experiences. Emerging technologies include:

- Touch-sensitive surfaces enabling control of devices through accessory interaction

- Haptic feedback providing tactile responses to notifications or interactions

- Environmental sensors detecting conditions like temperature, humidity, or air quality

- Biometric monitoring tracking health metrics through wearable accessories

The successful integration of these technologies requires careful design to ensure they enhance rather than compromise the aesthetic qualities of accessories. Our approach focuses on making technology virtually invisible during normal use while providing clear benefits when needed.

What sustainable technologies are shaping accessory production?

Environmental considerations are driving technological innovations that reduce the ecological impact of accessory manufacturing while maintaining quality and aesthetic standards.

Sustainable technologies include eco-friendly materials, waste-reduction systems, energy-efficient processes, and circular economy approaches that minimize environmental impact throughout the product lifecycle.

What material innovations support sustainability?

Advanced eco-materials offer environmentally responsible alternatives to traditional materials. Key developments include:

- Bio-based polymers derived from renewable resources like corn, algae, or mushroom roots

- Recycled materials including regenerated metals, plastics, and textiles

- Plant-based leather alternatives made from pineapple leaves, apple peels, or cactus

- Sustainable dyeing processes using water-free methods or natural pigments

Our material innovation lab continuously researches and tests new sustainable materials, with 35% of our current collections incorporating eco-friendly alternatives. The challenge lies in matching the aesthetic qualities and performance characteristics of traditional materials while improving environmental profiles.

How are production technologies reducing environmental impact?

Efficiency-focused manufacturing systems minimize waste and energy consumption. We've implemented:

- Water-free dyeing technologies like supercritical CO2 dyeing that eliminate water pollution

- Zero-waste pattern cutting using computer optimization to maximize material utilization

- Energy-efficient equipment with smart systems that reduce power consumption during non-production periods

- Closed-loop recycling systems that reprocess production waste into new materials

These technologies have reduced our manufacturing waste by 62% and decreased energy consumption by 45% per accessory produced. The economic benefits of these efficiency improvements have helped offset the costs of implementing sustainable technologies.

How are customization technologies changing accessory personalization?

Advanced technologies have made mass customization economically viable, allowing personalization at scale while maintaining production efficiency.

Customization technologies include digital configuration platforms, adaptive manufacturing systems, laser engraving, and on-demand production that enable personalized accessories without traditional cost premiums.

What digital tools enable accessory personalization?

Interactive customization platforms allow customers to co-create their accessories. We've developed:

- 3D configurators that provide real-time visualization of custom designs

- Augmented reality apps allowing customers to see how personalized accessories will look when worn

- Digital material libraries showing accurate representations of customization options

- AI style assistants that suggest personalized combinations based on individual preferences

These tools have increased customer engagement with customization options by 300% and improved satisfaction with final products by reducing the gap between expectation and reality. Customers can now make informed decisions about personalization with realistic previews of how their choices will appear.

How do manufacturing technologies support customization?

Flexible production systems enable efficient personalization. Key technologies include:

- Digital printing allowing economical short-run production of customized patterns

- Laser engraving providing precise personalization of text, images, or patterns

- Adaptable assembly lines that can efficiently handle variable specifications

- Additive manufacturing creating custom components without expensive tooling

Our implementation of these technologies has reduced the cost premium for customized accessories from 150% to just 25% above standard versions, making personalization accessible to a much broader customer base while maintaining profitability.

Conclusion

The creation of fashionable accessories is being transformed by multiple technologies that enhance design capabilities, manufacturing precision, functional possibilities, environmental responsibility, and personalization options. The most successful accessory brands are those that strategically integrate these technologies to enhance their creative vision and production capabilities.

The ongoing technological evolution in accessory creation represents both a challenge and an opportunity. Brands that embrace these changes while maintaining their design identity and quality standards will lead the industry into an increasingly technologically integrated future.

As technologies continue to advance and become more accessible, their influence on accessory design and production will only grow, offering exciting possibilities for innovation and improvement across all aspects of the industry.

If you're interested in leveraging these technologies for your accessory collections and would like to benefit from our experience in technological integration, we invite you to contact our Business Director, Elaine. She can guide you through our technological capabilities and help you develop an implementation strategy aligned with your brand vision. Reach her at: elaine@fumaoclothing.com.