When sourcing accessories from overseas, one bad supplier contract can lead to late deliveries, poor quality, or payment nightmares.

A strong accessory supplier agreement should clearly define responsibilities, quality standards, pricing, delivery terms, dispute resolution, and compliance. This helps avoid miscommunication and protects both parties' interests.

If you’re working with a Chinese factory like ours, you’ll want to understand the essential elements of supplier agreements and supplier relationship management. Let’s break them down together.

What should be included in a supplier agreement?

If you’ve ever received late or defective products from a supplier, chances are the agreement wasn’t clear—or wasn’t followed at all.

A supplier agreement should cover product specifications, price, payment terms, delivery schedules, penalties for delay, quality control process, confidentiality, intellectual property rights, and dispute resolution mechanisms.

Why do product specifications, QC terms, and delivery timelines need to be defined in detail—even if you trust your supplier?

Trust is important, but in business, clarity is even more critical. Each accessory order—whether it’s a batch of hair clips or branded scarves—should come with a clear breakdown of specifications. This includes material, size, color, packaging, labeling, and even finish. QC clauses should state how and when inspections happen, what standards apply (AQL or custom), and who pays for reworks. Delivery schedules should include INCOTERMS, shipment method, port, and penalties for delays. In our own experience with large American brands, these sections are non-negotiable.

How can payment terms and IP protection clauses save your business in unexpected situations?

Without defined payment terms, cash flow becomes unpredictable. A typical term might be 30% upfront, 70% after inspection or before shipping. But what if the shipment delays? What if inspection fails? That’s where fallback terms help. Intellectual property (IP) clauses are just as crucial—especially when dealing with new accessory designs or customized branding. A solid agreement will prevent suppliers from selling your designs to other buyers. In our factory, we sign NDAs and IP protection clauses as part of every long-term partnership.

What are the four key elements of supplier management?

Most importers focus only on price. But real success in supply chain management requires going beyond cost.

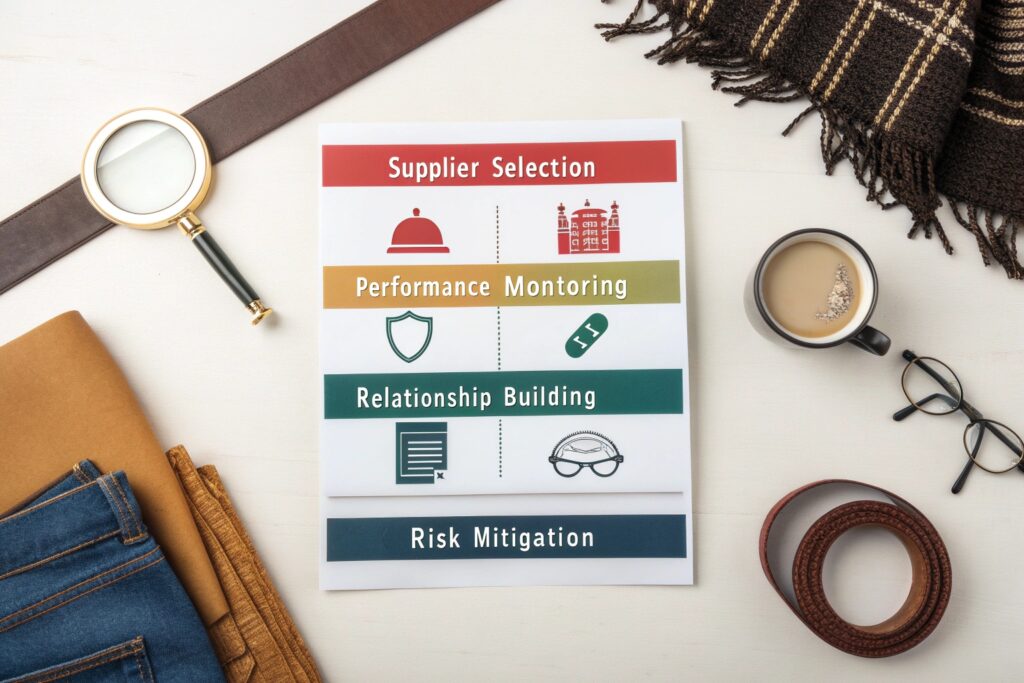

The four key elements of supplier management are: supplier selection, performance monitoring, relationship building, and risk mitigation. These ensure consistency, transparency, and mutual benefit in every order.

How can you evaluate and select the right supplier for long-term success?

Start with clear benchmarks: production capacity, past export history, audit records, factory location, team experience, and product expertise. For accessories, I always test development speed—how quickly can the supplier sample a new belt or headband? I also look at how proactive they are. Do they respond fast? Can they offer suggestions? At AceAccessory, we present new product trends each quarter to help buyers stay competitive. Supplier selection isn’t just due diligence—it’s long-term strategy.

Why should you regularly review supplier performance even if there are no complaints?

Silence doesn’t always mean satisfaction. You should track KPIs like on-time delivery rate, defect rate, communication speed, and responsiveness. A quarterly review call or report helps catch issues early. For instance, one of our US clients sends a monthly scorecard. When we noticed our delivery ETA slipped twice, we adjusted production flow immediately. Without that feedback loop, they could have switched suppliers. Monitoring performance isn’t micromanagement—it’s risk control.

What are the three key elements of a binding contract?

Verbal promises are common in global trade, but they often lead to confusion. You need more than just a handshake.

The three key elements of a binding contract are: offer and acceptance, mutual intent to create legal obligations, and consideration (value exchange). Without these, your agreement may not be enforceable.

Why does offer and acceptance have to be clearly documented in international sourcing?

In cross-border trade, misunderstanding is easy. A simple quote from a supplier doesn’t always count as a formal offer. The buyer must place an order referencing that offer, and the supplier must confirm acceptance—ideally in writing. This sequence forms the foundation of the deal. For example, when we onboard new buyers, we send a Proforma Invoice that lays out terms. The buyer signs or confirms in email. That simple confirmation protects both sides.

How does “consideration” make a contract legally binding even if it’s informal?

Consideration means both sides are giving up something of value. In supplier deals, it's usually money versus goods. If you order custom umbrellas and agree to pay $5,000, that exchange of goods and cash is your consideration. Courts will usually honor this if a dispute arises. But if there’s no price, no clear product, or no agreed delivery date—then there’s no valid contract. Even an email thread with these elements can work. But I always recommend a formal PO or agreement.

What are the three basic components of supplier relationship management?

A contract starts the relationship. But real value comes from how the partnership is managed over time.

The three basic components of supplier relationship management (SRM) are: communication, collaboration, and continuous improvement. These help turn transactional suppliers into strategic partners.

How can consistent and transparent communication lower the risk of misunderstandings and disputes?

We’ve seen it many times—buyers only email when things go wrong. But real SRM is proactive. You should have regular check-ins before each season starts, after each delivery, or even monthly. Sharing forecasts, promotions, or product roadmap helps the supplier prepare. In our company, we ask clients for sales feedback after each shipment. If a hairband didn’t sell well, we’ll stop producing it. If a scarf trend is taking off, we develop new patterns fast. Communication builds trust and efficiency.

Why does collaboration and continuous improvement separate average suppliers from great ones?

The best accessory suppliers don’t just follow—they innovate. When a client in Europe asked us to redesign packaging for more sustainability, we didn’t just say yes. We researched biodegradable bags, sourced FSC-certified tags, and redesigned the entire line. That collaboration helped them win a retail award. Good SRM includes supplier development, co-branding, and knowledge sharing. Ask yourself: does your supplier push new ideas? Do they help solve your logistics headaches? If yes, then you’ve found a strategic partner.

Conclusion

Clear agreements and strong supplier relationships reduce risk and improve every part of your accessory business.