Choosing the right fabric is one of the most critical decisions in fashion and accessory design. It affects everything from the drape of a scarf to the structure of a baseball cap. For buyers sourcing products, understanding the fundamental difference between woven and knitted fabrics is essential for quality, cost, and end-use. At AceAccessory, where we produce a wide range of items from woven belts to knitted hats, we navigate these choices daily to ensure every product meets its intended purpose.

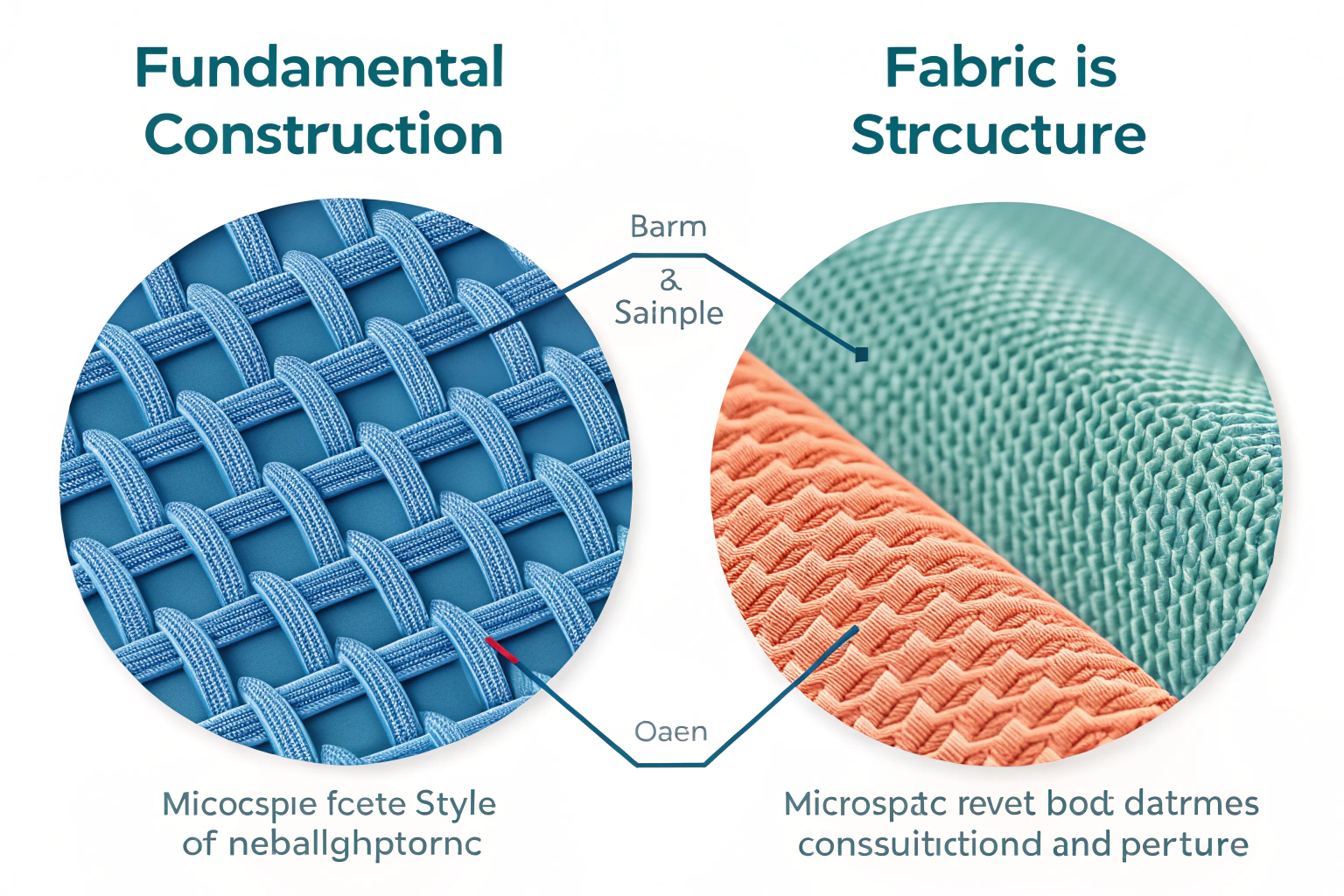

The key difference lies in their construction: woven fabrics are made by interlacing two sets of yarns (warp and weft) at right angles, creating a stable, structured, and often non-stretch material. Knitted fabrics are made by interlocking loops of yarn with a single continuous thread, resulting in a flexible, stretchy, and breathable material. This core structural distinction dictates their behavior, applications, and care requirements in finished products like apparel and accessories.

This choice isn't just academic—it directly impacts your product's performance, customer satisfaction, and manufacturing process. Let's unravel the specifics of each type to guide your next sourcing decision.

How are Woven and Knitted Fabrics Constructed?

The journey of any fabric begins with its construction method, which fundamentally defines its identity. Imagine building a structure: one method uses a grid of intersecting beams, while another uses a chain of interconnected links. This is the essence of the weave versus knit divide. For a manufacturer, knowing which method to use is the first step in creating a product with the right properties, whether it's a sturdy belt or a comfortable glove.

Woven fabrics are created on a loom. Two distinct sets of yarns—the lengthwise warp and the crosswise weft—are interlaced perpendicularly. This creates a strong, stable grid-like structure. The most basic pattern is the plain weave, but variations like twill (denim) or satin create different textures and strengths. Because the threads are straight and locked under tension, woven fabrics have little inherent stretch along the length or width, though they can be cut on the bias (diagonally) for some give. Conversely, knitted fabrics are made on knitting machines (or by hand) using one continuous yarn (or multiple yarns) formed into a series of interlocking loops. This looped structure, like a chain, allows the fabric to stretch significantly in multiple directions when pulled. The two main types are weft knitting (where loops are made horizontally, as in sweaters) and warp knitting (where loops are made vertically, often used in sportswear).

What are the Common Weave Patterns and Their Uses?

Woven fabrics offer a variety of patterns, each with unique characteristics perfect for different fashion accessories:

- Plain Weave: The simplest and most common (e.g., chiffon, taffeta). It's balanced, durable, and often used for scarves or linings.

- Twill Weave: Creates a diagonal rib pattern (e.g., denim, gabardine). It's durable, dense, and drapes well, making it ideal for structured caps and durable bags.

- Satin Weave: Features long yarn "floats" on the surface, creating a smooth, lustrous, and delicate face (e.g., charmeuse, satin). It's often used for luxurious shawls and decorative hair accessory bands.

Understanding these weaves helps in selecting the right fabric for a product's functional and aesthetic needs. For a deeper dive into textile engineering, resources like Textile School provide excellent technical overviews.

How Does the Knitting Process Create Stretch?

The inherent stretch of knits comes from the looped construction. When force is applied, the loops can expand and distort, then return to shape. The type of knit stitch determines the stretch and recovery:

- Jersey Stitch (Single Knit): The most common, used for T-shirts. It curls at the edges and has moderate stretch. This is typical for lightweight knit hats.

- Rib Knit: Creates vertical ridges with excellent crosswise stretch, perfect for cuffs, collars, and headband linings.

- Interlock Knit: A double-knit that is stable, smooth on both sides, and more resistant to curling, often used for higher-quality polo shirt fabrics that could translate to structured yet comfortable accessories.

The machinery, like circular knitting machines for seamless tubes (great for headwear), is a key part of our production at Shanghai Fumao Clothing. This knowledge directly impacts the development capacity for accessories, ensuring the chosen fabric construction aligns with the product's required flexibility and shape. For those interested in machinery, the International Textile Manufacturers Federation (ITMF) tracks global trends in knitting technology.

Which Fabric is More Durable: Woven or Knitted?

Durability is a top concern for buyers like Ron, who need products that withstand use and maintain quality. The question of durability isn't simple, as "durability" can mean resistance to tearing, abrasion, pilling, or stretching out of shape. The answer depends heavily on the fabric's intended use. A fabric perfect for a sturdy tote bag would be a poor choice for a form-fitting activewear headband.

Generally, woven fabrics excel in tensile strength and resistance to abrasion and tearing due to their tight, straight-thread interlacing. A high-thread-count cotton woven, like canvas or denim, is extremely tough and ideal for products requiring structure and load-bearing, such as belts, bag bodies, and certain types of hats. However, wovens can be prone to fraying when cut, requiring finished seams. Knitted fabrics, while flexible and resistant to wrinkling, are generally less resistant to abrasion and snagging. A loose loop can catch and pull, creating a "ladder." Their durability lies in their elasticity and ability to withstand repeated stretching without tearing. A well-knit jersey or ribbed cuff can endure countless stretches. For products like gloves or compressive sportswear accessories, this stretch-recovery is the definition of durability.

How Does Fiber Content Interact with Construction?

Durability is a partnership between construction and material. A woven fabric made from delicate silk will be less durable than a knitted fabric made from robust nylon. Common pairings include:

- Woven + Natural Fibers (Cotton, Linen): Creates strong, breathable fabrics for structured hats and tote bags.

- Woven + Synthetic Fibers (Polyester, Nylon): Creates exceptionally strong, fade-resistant, and weather-resistant fabrics for outdoor accessories and rain umbrella canopies.

- Knit + Cotton: Creates soft, breathable, and comfortable fabrics for beanies and headbands, though may be prone to shrinking.

- Knit + Synthetic/Blends (Polyester, Spandex): Creates durable, stretchy, shape-retentive, and quick-drying fabrics ideal for performance wear accessories and activewear.

For authoritative information on fiber properties, the Textile Institute is a global resource.

What are the Common Failure Points for Each?

Understanding potential weaknesses helps in design and quality control:

- Woven Fabric Failures:

- Fraying at cut edges.

- Seam failure if not reinforced, as the fabric itself doesn't give.

- Wrinkling and creasing.

- Knitted Fabric Failures:

- Snagging and pulling of loops.

- Pilling (formation of small fiber balls) on the surface with friction.

- Stretching out (losing recovery) if made from low-quality yarn or improper knit.

A strong QC team will test for these failures. At Shanghai Fumao Clothing, we conduct martindale abrasion tests for wovens and repeated stretch tests for knits to ensure the accessories we produce, from woven purses to knitted scarves, meet durability expectations. This proactive testing is part of what defines a manufacturer with strong development capacity.

How Does Fabric Choice Impact Garment Drape and Fit?

The drape—how a fabric falls or hangs—and the resulting fit of a finished product are artistic and functional qualities directly dictated by the fabric's construction. This is where the tactile and visual design of an accessory comes to life. A flowing shawl requires a different hand-feel than a fitted cap. The choice between woven and knit is the primary driver of this characteristic.

Woven fabrics, due to their stable structure, offer more control and crispness. They hold shapes well—think of the sharp brim of a sun hat or the structured body of a belt. Their drape can range from stiff (canvas) to fluid (chiffon), but it is generally a controlled fall. They are ideal for tailored, structured items where a defined silhouette is desired. Knitted fabrics, by contrast, are champions of fluidity and conformability. They drape softly and stretch to fit the body or object they cover. This makes them perfect for items that require ease of movement and a soft, comfortable touch, such as infinity scarves, stretchy headbands, and form-fitting gloves. The fit is inherently more forgiving and adaptive with knits.

How Do Weight and Density Affect Drape?

Within each construction type, subtleties matter:

- Woven Drape Factors: A lightweight, loosely woven silk georgette will have a soft, flowing drape for an elegant wrap. A heavy, densely woven wool melton will have a stiff, architectural drape for a structured cape. The yarn thickness and weave tightness are key.

- Knit Drape Factors: A lightweight single jersey will have a soft, clingy drape. A heavier double-knit or cable-knit will have more body and a bulkier, more vertical drape, perfect for a chunky winter headband.

Selecting the correct weight is a core part of our design team's role when developing new accessory samples for clients.

Why is Fit More Forgiving with Knitted Fabrics?

The forgiving nature of knits comes from their elasticity. They can accommodate a range of sizes because they stretch. This reduces the need for complex pattern pieces and precise fitting, often simplifying manufacturing. For example, a knitted beanie can often be "one-size-fits-most" due to the fabric's stretch, whereas a woven fabric cap requires precise sizing and multiple pattern parts (crown, brim, band) to achieve a fit. This impacts everything from sizing charts to inventory management for retailers. Understanding these principles is part of professional customer energy, helping clients choose the right path for their market. For insights into pattern-making for different fabrics, resources from The Fashion Institute of Design & Merchandising (FIDM) can be valuable.

Which is Better for Accessories: Woven or Knitted Fabrics?

There is no universal "better" option. The optimal choice is 100% dictated by the accessory's function, desired aesthetic, and target cost. Asking this question is like asking whether a screwdriver or a hammer is better—it depends on the task. A successful sourcing strategy involves matching the fabric's inherent properties to the product's goals. At AceAccessory, we guide clients through this decision daily, ensuring the material serves the design.

The decision matrix is practical. Use woven fabrics when you need structure, stability, crisp detailing, and minimal stretch. Use knitted fabrics when you need stretch, comfort, conformability, and a soft drape. Often, the best product uses both: a woven straw hat with a knitted sweatband, or a woven canvas bag with knitted stretchy side panels. This hybrid approach leverages the strengths of each. For help evaluating a factory's capability with both, consider the points in our guide on How to Verify Quality Control in Accessories Manufacturing.

What are Ideal Applications for Woven Fabrics in Accessories?

Woven fabrics shine in accessories that require shape retention and durability:

- Belts & Straps: Require non-stretch strength.

- Structured Hats (Baseball caps, Bucket hats, Straw hats): Need a body that holds its form.

- Bags & Totes: Need to carry weight without distorting.

- Neckties & Bows: Rely on a crisp, defined shape.

- Decorative Appliqués & Patches: Hold their shape when attached.

These items benefit from the precision that woven fabric offers, and their production often involves more precise cutting and sewing, which is a core part of our fast production processes for such goods.

What are Ideal Applications for Knitted Fabrics in Accessories?

Knitted fabrics are the go-to for comfort, stretch, and warmth:

- Hats & Beanies: Conform to the head for warmth and comfort.

- Scarves, Snoods, & Infinity Loops: Drape softly and stretch for easy wrapping.

- Gloves & Mittens: Stretch to fit the hand shape.

- Headbands & Wristbands: Stay in place through elasticity.

- Socks & Leg Warmers: Require all-around stretch and recovery.

The fast development of new knit accessories is often easier for trending items, as knit structures can be quickly programmed into machines to produce new textures. Furthermore, the logistics of shipping knit items like scarves can be more efficient as they often pack down smaller than structured wovens. For market-specific trends, platforms like WGSN are key for forecasting fabric and accessory directions. A partner like Shanghai Fumao Clothing can help navigate these choices while managing complex aspects like US tariffs.

Conclusion

The choice between woven and knitted fabrics is a foundational decision in product creation, impacting durability, fit, function, and aesthetics. Wovens offer structure and stability, while knits provide flexibility and comfort. The most successful fashion lines and accessory collections often intelligently employ both, using each for its inherent strengths. Understanding this distinction empowers you to make informed sourcing decisions, specify materials correctly, and ultimately deliver better products to your customers.

This knowledge translates directly to smoother manufacturing, fewer surprises, and a product that performs as expected. It allows for clearer communication with your factory and a more collaborative development process.

Ready to apply this knowledge to your next accessory line? Whether you're developing a line of structured woven belts or cozy knitted winter sets, having a manufacturing partner who deeply understands these textiles is crucial. Shanghai Fumao Clothing specializes in turning fabric knowledge into beautifully executed products. Contact our Business Director Elaine today at elaine@fumaoclothing.com to discuss how we can help you choose the perfect fabric and manufacture your next best-selling accessory collection.