Pearl-embellished hair hoops represent a challenging accessory category where delicate materials meet precise manufacturing requirements. Traditional production methods struggle with consistency, efficiency, and quality control in these intricate pieces. Through our implementation of smart production systems, we've identified key elements that transform how these fashionable accessories are designed, produced, and brought to market.

Smart production for pearl-embellished hair hoops integrates digital design platforms, automated pearl handling systems, robotic assembly precision, real-time quality analytics, and adaptive manufacturing workflows that collectively elevate quality while optimizing efficiency.This technological ecosystem addresses the unique challenges of combining delicate pearls with metal or plastic hoops at scale.

The transformation from traditional to smart production represents a fundamental rethinking of how delicate accessories are manufactured. Let's examine the specific elements that constitute this advanced manufacturing approach.

How do digital design and prototyping systems enhance development?

Traditional hair hoop development involves physical prototyping that consumes significant time and resources while limiting creative exploration. Digital design platforms transform this process by enabling virtual creation, testing, and refinement before any physical materials are committed.

Digital design elements provide the foundation for smart production by ensuring designs are both aesthetically compelling and manufacturable with consistent quality.

What 3D modeling capabilities optimize pearl placement?

Physical prototyping of pearl-embellished designs requires multiple iterations to perfect pearl arrangement and spacing. Our advanced 3D modeling software allows designers to create virtual hair hoops with precise pearl placement, visualizing how light interacts with different pearl sizes, shapes, and orientations. The software includes material simulation that accurately represents how pearls will appear against various hoop materials and finishes. Designers can instantly test dozens of arrangement patterns—symmetrical, graduated, clustered, or asymmetric—evaluating aesthetic impact without creating physical samples. This digital approach has reduced our development time by 60% while enabling more creative experimentation within the same timeframe.

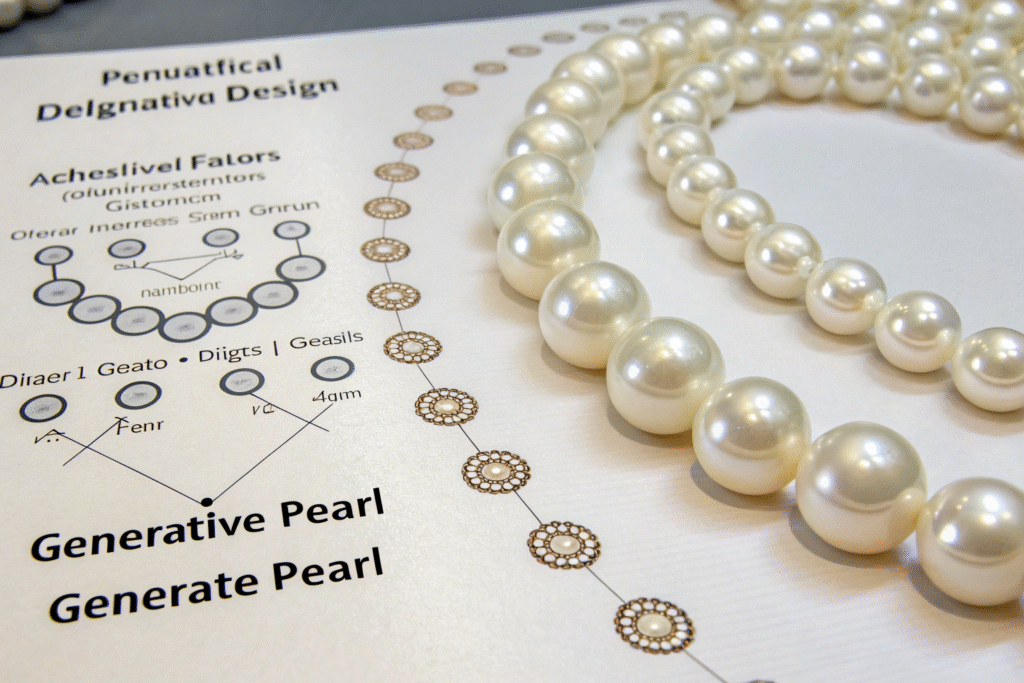

How does computational design generate innovative patterns?

Human designers naturally gravitate toward familiar arrangements, while computational systems explore unconventional possibilities. We've integrated generative design algorithms that create unique pearl arrangements based on specified parameters like pearl inventory, price targets, and style preferences. These systems produce patterns that human designers might never consider, often resulting in breakthrough designs with distinctive aesthetic appeal. The algorithms optimize for both visual impact and manufacturing efficiency, rejecting arrangements that would be difficult to execute with consistent quality. This human-computer collaboration has expanded our design vocabulary while increasing the commercial success rate of new introductions.

What automated handling systems ensure pearl integrity?

Pearls represent delicate natural materials that require careful handling to prevent damage during manufacturing. Traditional manual handling introduces significant breakage risk and consistency challenges, particularly with smaller or irregularly shaped pearls.

Automated pearl handling systems bring gentle precision to material management while maintaining the consistency impossible to achieve manually.

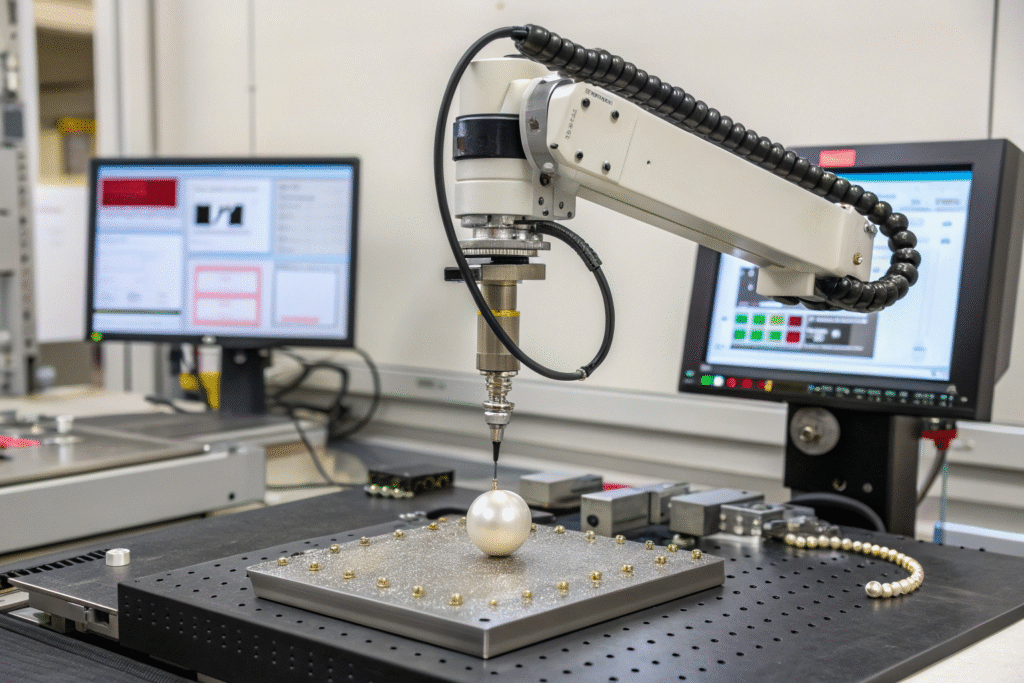

How do vision-guided robotic systems select and orient pearls?

Manual pearl selection and orientation introduces subtle variations that affect final product appearance. Our AI-powered vision systems analyze each pearl from multiple angles, assessing characteristics including size, shape, luster, surface quality, and optimal orientation for maximum visual impact. The systems then guide gentle robotic grippers that position each pearl with precise orientation relative to the hair hoop base. For designs requiring specific pearl relationships, the system calculates optimal arrangement sequences that maintain visual harmony while accommodating natural pearl variations. This automated handling has reduced pearl damage during production by 80% while ensuring consistent visual quality across production runs.

What vibration feeding and sorting systems organize pearl inventory?

Traditional pearl organization requires manual sorting that consumes significant labor while introducing handling damage risk. Our smart production lines incorporate gentle vibration feeding systems that organize pearls by size and orientation without surface damage. Optical sorting technology categorizes pearls by multiple characteristics simultaneously—size, shape, color tone, and surface quality—creating organized inventory ready for specific designs. The system maintains real-time inventory tracking that matches pearl characteristics to design requirements, automatically flagging shortages or quality issues before production begins. This automated organization has streamlined our material management while ensuring perfect pearl-design matching.

How does robotic assembly achieve precision attachment?

Pearl attachment represents the most critical manufacturing stage where consistency challenges become most apparent. Manual assembly inevitably introduces variations in adhesive application, placement accuracy, and pressure control that affect both appearance and durability.

Robotic assembly systems bring engineering precision to pearl attachment, executing each operation with consistent accuracy regardless of production volume or complexity.

What micro-dispensing systems ensure consistent adhesive application?

Manual adhesive application varies significantly between operators and even within a single operator's work cycle. Our precision micro-dispensing systems apply exact adhesive quantities measured in microliters, ensuring consistent bond strength without visible residue. The systems use vision-guided positioning that places adhesive only where needed, preventing overflow that can dull pearl luster. For different pearl sizes and hoop materials, the system automatically adjusts adhesive viscosity and volume to create optimal bonds. This precision application has eliminated the adhesive-related quality issues that previously caused pearl loss or aesthetic complaints, while reducing adhesive usage by 35% through minimized waste.

How does force-controlled placement prevent pearl damage?

Manual pearl placement risks damaging delicate pearl surfaces through uneven pressure application. Our force-controlled robotic placers maintain exact pressure profiles throughout the placement process, ensuring secure attachment without surface compression or cracking. The systems include real-time pressure monitoring that detects resistance variations, automatically adjusting placement parameters to accommodate natural pearl irregularities. For clustered arrangements where pearls contact each other, the system calculates optimal placement sequences that prevent interference while maintaining perfect spacing. This gentle precision has reduced pearl damage during assembly to near zero while ensuring every pearl sits at its optimal angle and height.

How do real-time quality systems ensure excellence?

Pearl-embellished hair hoops require meticulous quality control where traditional sampling methods miss subtle defects. Real-time quality systems transform inspection from periodic checking to continuous verification, catching issues at their source rather than after completion.

Integrated quality elements provide comprehensive assurance throughout manufacturing rather than just final inspection.

What machine vision inspection detects microscopic defects?

Human inspection cannot reliably identify the subtle imperfections that affect luxury hair hoop quality. Our high-resolution vision systems examine every pearl and attachment point from multiple angles with magnification up to 50x, detecting issues like micro-fractures, adhesive traces, orientation errors, and surface imperfections. The systems compare each piece against digital quality standards rather than subjective human judgments, ensuring consistent rejection criteria. For pearl luster verification, multi-angle lighting systems assess light reflection consistency across all pearls in a design. This automated inspection has improved our defect detection rate by 90% while eliminating the inspection fatigue that plagues manual quality control.

How does spectral analysis verify material authenticity?

The luxury positioning of pearl-embellished hair hoops depends on material authenticity that visual inspection cannot verify. Our integrated spectral analysis systems verify pearl authenticity and quality through non-destructive testing that identifies natural pearls versus alternatives. The systems also verify metal composition for hoops, ensuring precious metal claims are accurate. This material verification occurs seamlessly within the production flow, providing certification documentation automatically while preventing material substitution or quality misrepresentation. The integration of material verification within production has strengthened our quality assurance while building trust with brand partners and consumers.

How do adaptive workflows enable mass customization?

The future of hair accessories lies in personalization, but traditional manufacturing struggles with custom orders. Smart production systems incorporate flexible workflows that accommodate customization without sacrificing efficiency or quality.

Adaptive manufacturing elements transform production from rigid sequences to responsive systems that maintain quality regardless of order characteristics.

What digital twin technology enables customization verification?

Traditional custom orders risk manufacturing issues that only appear during physical production. Our digital twin platform creates virtual replicas of custom designs, simulating how they will appear and function before manufacturing begins. The system verifies that custom requests are manufacturable within quality standards, suggesting modifications when necessary. For personalized pearl arrangements, the platform allows customers to visualize their designs from multiple angles with accurate material representation. This virtual verification has eliminated the customization errors that previously resulted in remakes and delays, while giving customers confidence in their personalized designs.

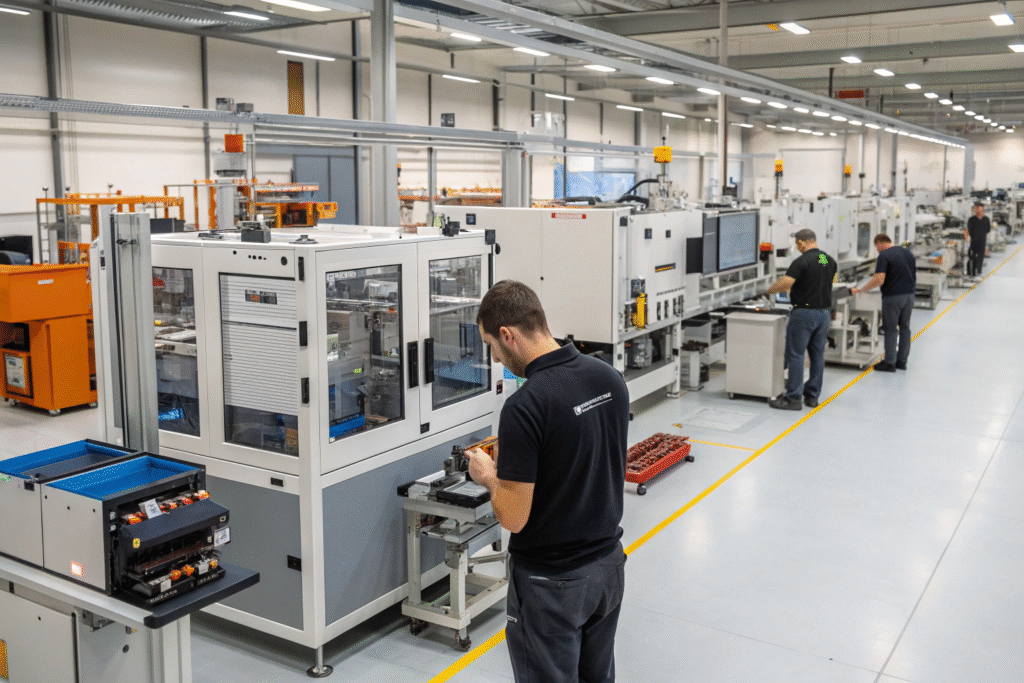

How do flexible manufacturing cells handle variable orders?

Traditional production lines optimized for volume struggle with custom orders that disrupt workflow. Our modular manufacturing cells can be rapidly reconfigured for different hair hoop styles and pearl arrangements without significant downtime. The cells feature equipment with quick-change capabilities that adjust to different hoop sizes, pearl types, and attachment methods. Universal fixtures accommodate various design geometries while maintaining precise positioning for automated processes. This flexibility enables us to efficiently produce small batches of customized hair hoops alongside volume production, creating premium revenue streams without sacrificing efficiency in our core business.

Conclusion

Smart production for pearl-embellished hair hoops integrates multiple advanced elements that collectively transform manufacturing from traditional craft to precision engineering. The combination of digital design, automated handling, robotic assembly, real-time quality systems, and adaptive workflows creates a manufacturing environment that achieves superior quality, efficiency, and flexibility simultaneously. Companies implementing these smart production elements position themselves at the forefront of accessory manufacturing, capable of delivering the exquisite quality that justifies luxury positioning while operating with efficiencies that support healthy business performance.

If you're interested in implementing smart production elements for your pearl-embellished hair hoop collections, we invite you to contact our Business Director, Elaine. Our experience in integrating advanced manufacturing technologies can help you achieve similar transformations in quality, efficiency, and customization capability. Reach her at: elaine@fumaoclothing.com.