Labels may be small, but they carry your brand identity. When they fade, fray, or fall off, customers remember. That’s why it’s critical to get them right—from the weaving technique to the stitching margin. Zhejiang factories in China offer speed, consistency, and flexibility that global brands rely on.

To source high-quality woven labels, Zhejiang factories stand out due to their mature supply chain, skilled technicians, competitive pricing, and capacity for customized design and quick sampling.

At AceAccessory, we’ve helped brands of all sizes create woven labels that elevate product quality and meet global compliance. Here’s what makes Zhejiang the smart choice.

What are woven labels used for?

Woven labels are more than branding—they’re a signal of quality. They provide information, enhance aesthetics, and contribute to the overall consumer experience.

Woven labels are used for branding, sizing, care instructions, and compliance information on fashion items like clothing, accessories, and home textiles. Their durability and tactile appeal make them ideal for permanent identification.

Common Woven Label Applications

| Product Type | Label Function |

|---|---|

| T-shirts | Brand logo, size tag, care label |

| Coats & Jackets | Main label, inside brand label, lining tag |

| Hats & Headwear | Side logo tab, size tab |

| Bags & Backpacks | Logo tag, barcode label |

| Scarves & Gloves | Fiber content, brand name |

| Belts | Woven size loop, decorative tag |

Woven labels differ from printed ones by offering a more premium texture, higher washing durability, and the option to weave in multi-color logos without ink.

At AceAccessory, we offer damask, satin, and taffeta woven labels with cut-and-fold options including center fold, end fold, and Manhattan fold to suit your garment construction.

What is the importance of fabric sourcing?

Labels don’t exist in isolation—they must match the fabrics and styles of your product line. That’s why understanding fabric sourcing helps create harmonious accessories and garments.

Fabric sourcing is crucial because it determines texture, durability, cost, and label compatibility. Coordinating fabric and label selection ensures visual and physical consistency across the product.

How Fabric Choice Affects Label Strategy

| Fabric Type | Label Consideration |

|---|---|

| Knit (e.g., jersey) | Lightweight label, soft back stitching |

| Wool or fleece | Larger backing for grip, woven edge sealing |

| Satin or silk | Narrow folded labels, fine thread weaving |

| Denim or canvas | Thick label with strong stitching tolerance |

| Stretch fabrics | Labels with heat-cut edges, high elasticity |

Zhejiang’s label factories often work alongside fabric mills. At AceAccessory, we source both in the same region, allowing our clients to match labels with textile swatches during the sampling stage.

This integrated sourcing minimizes color mismatch, stiffness issues, and design delays. We also test label friction, fold strength, and colorfastness before mass production.

Why is so much clothing made in China?

Despite rising labor costs, China remains the global leader in garment and accessory manufacturing. The reasons go far beyond low cost.

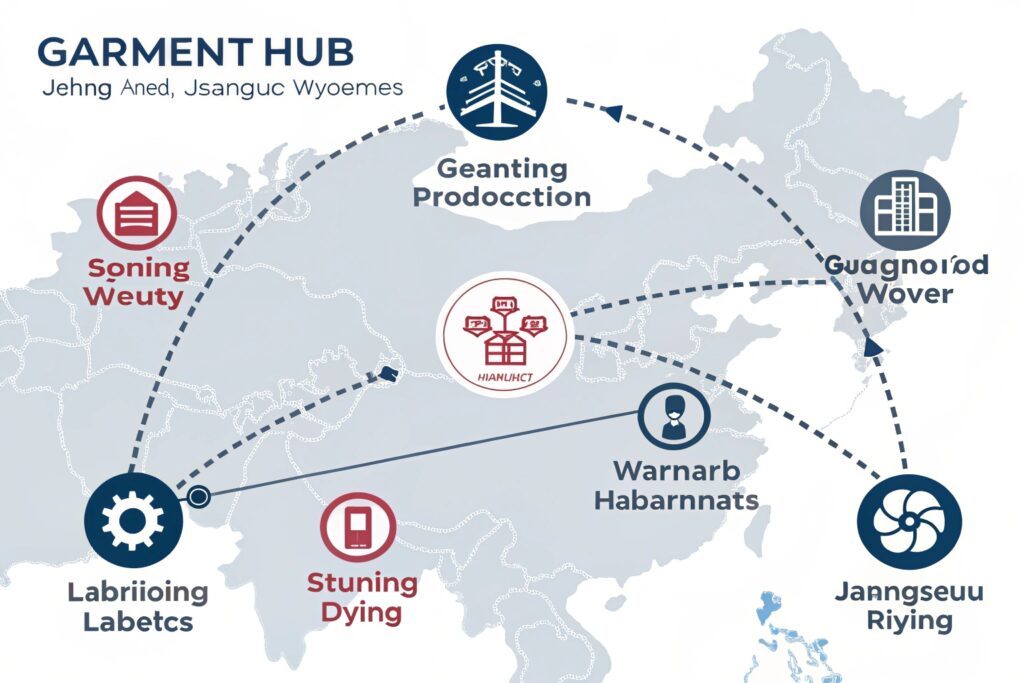

So much clothing is made in China because of its advanced infrastructure, skilled workforce, full vertical supply chain, and responsive production capabilities—especially in provinces like Zhejiang, Jiangsu, and Guangdong.

Advantages of China's Apparel Ecosystem

| Factor | Advantage for Fashion Brands |

|---|---|

| Vertical Integration | Fabric, trim, and label supply all in-house |

| Workforce Skills | Precision sewing, label placement expertise |

| Technology | Automatic weaving and QC equipment |

| Production Speed | Quick turnaround for samples and bulk orders |

| Export Experience | Familiarity with EU, US compliance |

In Zhejiang, we work with factories that synchronize label production with garment cutting lines. This means labels are ready exactly when assembly begins—avoiding bottlenecks.

At AceAccessory, we’ve helped DTC brands from the U.S. and Europe move their label sourcing to China—not just for cost savings, but for consistency and reliability at scale.

What clothing factories are in China?

Knowing the landscape of garment manufacturing helps you understand where to locate label sourcing as part of a broader supply plan.

China has thousands of clothing factories across key provinces like Zhejiang, Guangdong, Jiangsu, and Fujian. These factories specialize in everything from fast fashion to outdoor gear, and they often work closely with local label suppliers.

Clothing Factory Hotspots by Specialization

| City/Region | Strengths |

|---|---|

| Yiwu (Zhejiang) | Accessories, belts, hats, woven labels |

| Wenzhou (Zhejiang) | Leather belts, uniforms, trims |

| Shaoxing (Zhejiang) | Knits, woven fabric, fashion brands |

| Guangzhou (Guangdong) | Trend-driven clothing, activewear |

| Suzhou (Jiangsu) | Formalwear, outerwear |

Zhejiang is ideal for mid-size fashion brands that need flexibility. Label factories in this area can produce multi-language care labels, eco-certified threads, and retail-ready hangtags all under one roof.

AceAccessory offers label+garment bundling—so you don’t have to manage multiple suppliers or worry about component mismatch.

Conclusion

Woven labels may be small, but sourcing them from Zhejiang factories gives you a big advantage. With advanced weaving, fast turnaround, and full customization, these suppliers help elevate your accessory brand—and streamline production in ways that really matter.