When I first started working with large fashion retailers and importers in North America and Europe, I quickly learned that speed and accuracy could make or break a deal. Many factories had good products, but their management systems were outdated, relying on paper records or scattered spreadsheets. In contrast, factories with ERP (Enterprise Resource Planning) systems transformed the way we worked — giving us real-time visibility, seamless coordination, and the ability to deliver high-quality accessories with unmatched efficiency.

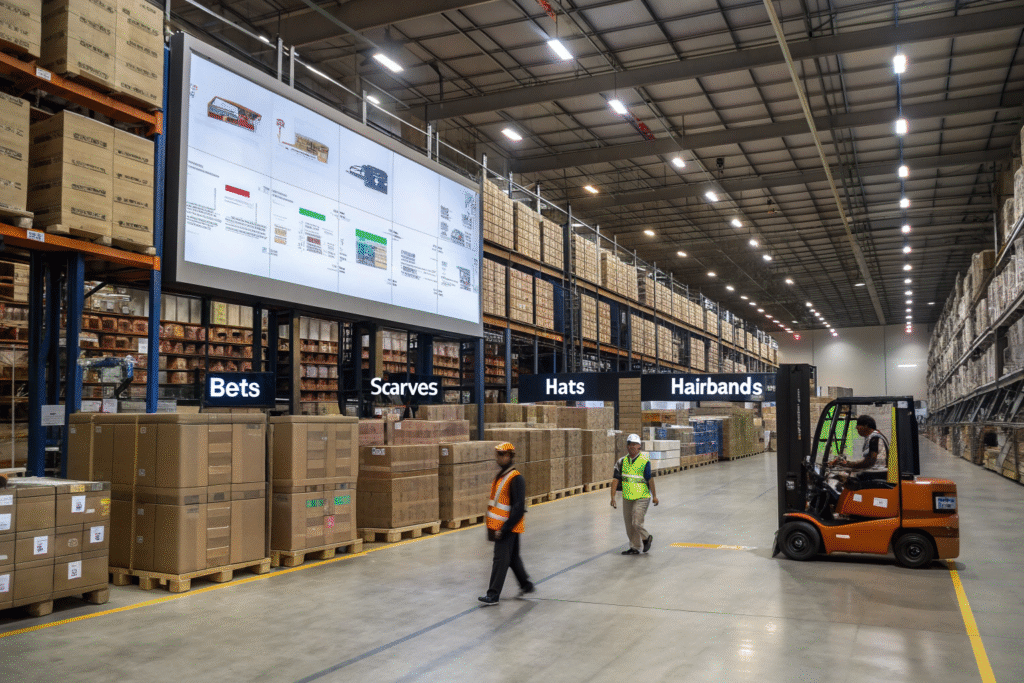

ERP systems give buyers like you direct benefits: lower errors, faster lead times, and transparent order tracking. Instead of juggling phone calls and endless emails, you can get accurate production data, inventory status, and shipping updates in real time. For accessories like hair clips, belts, scarves, and hats, where styles change quickly, ERP-driven factories help you stay ahead of seasonal trends.

By the end of this article, you’ll see why choosing a factory with ERP isn’t just about technology — it’s about getting peace of mind, better pricing, and consistent quality in every shipment.

How Does ERP Improve Production Efficiency?

ERP transforms production from a guessing game into a controlled process. Without ERP, accessory production often involves delays from miscommunication between departments. Fabric orders get lost, production lines stop, and deadlines are missed. This can damage your sales season, especially for trend-sensitive items like fashion scarves or seasonal hats.

ERP centralizes all production data, from material purchasing to quality checks, in one platform. This means fabric supply delays trigger instant alerts, enabling quick adjustments. It also optimizes machine schedules so every production step flows without idle time.

How Can Real-Time Data Reduce Delays?

Factories without ERP often depend on verbal updates or outdated spreadsheets. This leads to slow reaction times. With ERP, I can see exactly when a hairband order enters sewing, when belts are in inspection, and when scarves are packed. By integrating logistics updates, ERP even predicts delivery times more accurately. I once avoided a shipment delay for a large US department store because ERP flagged a material shortage a week early.

Can ERP Help Scale Orders Without Losing Quality?

Yes. Scaling from 10,000 to 50,000 pieces of belts or hats without ERP usually causes chaos. With ERP, work orders expand automatically, and quality control teams get notified to adjust inspection capacity. This prevents defects from slipping through during peak season.

Why Is ERP Critical for Quality Control?

In the fashion accessories industry, one defective shipment can hurt your brand. ERP adds structure and traceability to quality control. Every inspection result, photo, and report is logged in real time. This allows fast identification of which batch or material supplier caused an issue.

How Does ERP Make Quality Checks More Reliable?

Traditional QC processes rely heavily on manual notes, which can be incomplete or lost. With ERP, each QC checklist is digital and linked to specific orders. This way, if a hair clip shipment has a color mismatch, I can instantly trace it back to the dye batch and supplier.

Can Buyers Access QC Data Directly?

Yes, some ERP-enabled factories, including ours, can grant buyers limited portal access. This means you can view QC photos of your scarves or belts before they are shipped. One of my European clients reduced returns by 30% after using our ERP-based QC review system because they could approve products remotely before loading.

How Does ERP Support Better Inventory and Supply Chain Management?

ERP doesn’t just manage production; it controls the supply chain end-to-end. From raw material stock to finished goods ready for export, everything is visible in real time. This is especially important for accessories with seasonal demand peaks, like summer straw hats or winter knit scarves.

Can ERP Prevent Overstock and Stockouts?

Yes. ERP uses demand forecasting tools that match material purchasing with confirmed orders. For example, if belt orders drop, ERP automatically slows leather procurement to avoid excess inventory.

How Does ERP Help with Multi-Location Warehousing?

If you have distribution in both the US and Europe, ERP can split shipments and track them separately. I once managed a project where hats were sent to two regional DCs, and ERP ensured both received correct SKUs without mix-ups.

Why Does ERP Create Better Buyer-Supplier Communication?

Clear communication reduces risk in international sourcing. ERP bridges the gap between buyer expectations and factory execution. Instead of long email chains, ERP-based communication tools log all updates in one place — accessible to both sides.

Does ERP Replace the Need for Frequent On-Site Visits?

Not entirely, but it reduces them. Many buyers used to visit factories monthly to check progress. With ERP, you can monitor order status, QC reports, and shipping updates remotely. For example, one of my US wholesale clients cut travel costs by 50% after integrating ERP with our production flow.

Can ERP Integrate with Buyer’s Own Systems?

Yes. Some ERP systems support API integration, meaning your own order management platform can receive direct updates from the factory’s ERP. This reduces manual data entry errors and keeps your sales team aligned with actual factory output.

Conclusion

ERP transforms how accessory factories operate and how buyers like you experience sourcing. From production efficiency to quality control, inventory planning, and real-time communication, the benefits are clear: fewer errors, faster deliveries, and better transparency.

If you want your accessories — whether belts, scarves, hats, or hair clips — delivered with precision and speed, partnering with a factory that uses ERP is a strategic move. At AceAccessory, we’ve built our ERP-driven operations to match the needs of demanding buyers in the US and Europe. To start your own ERP-powered sourcing project, contact our Business Director Elaine at: elaine@fumaoclothing.com.