Energy costs represent one of the largest operational expenses in fashion accessory manufacturing. Between sewing equipment, injection molding machines, lighting systems, and climate control, factories consume substantial electricity and water. Traditional energy management often relies on manual readings and periodic audits, missing real-time optimization opportunities.

IoT technology transforms energy management in accessory manufacturing by providing real-time monitoring, automated control systems, predictive maintenance, and data-driven optimization across all energy-consuming processes.This connected approach can reduce energy costs by 15-30% while improving production efficiency and sustainability metrics.

Let's explore practical IoT applications that accessory manufacturers can implement to optimize their energy usage and reduce environmental impact.

How can IoT monitoring systems track energy consumption?

Most manufacturers only see energy usage through monthly utility bills, missing the detailed insights needed for meaningful optimization. Without granular data, identifying waste patterns and improvement opportunities becomes guesswork rather than science.

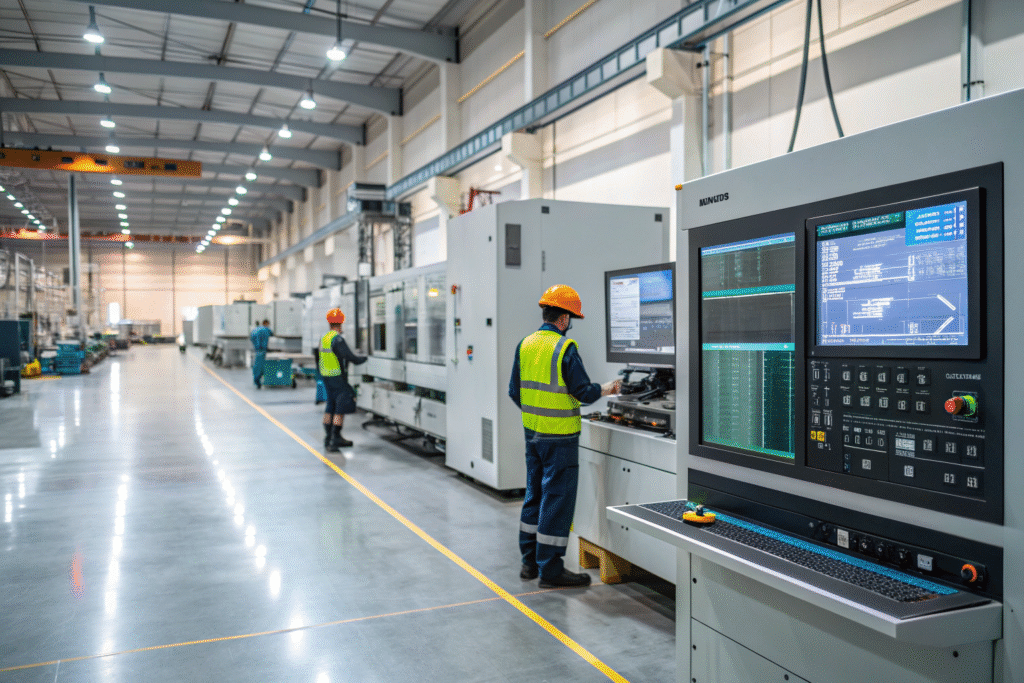

IoT energy monitoring installs connected sensors on individual machines, production lines, and facility systems to provide real-time visibility into exactly when, where, and how energy is consumed throughout manufacturing operations.

What types of IoT sensors are most valuable for energy management?

Smart meters on main power lines provide overall consumption patterns, while sub-metering sensors on individual machines like injection molders for hair clip production reveal specific energy hotspots. Temperature and humidity sensors optimize HVAC usage in different factory zones, and vibration sensors detect equipment inefficiencies that increase energy draw. Our implementation of wireless IoT sensors across our scarf knitting department identified that 40% of energy was consumed during non-production hours by idle equipment.

How does real-time data visualization drive energy savings?

IoT platforms transform raw sensor data into intuitive dashboards that show energy usage by department, machine, and shift. Color-coded alerts highlight abnormal consumption patterns immediately, allowing quick intervention. For example, when our accessory production line shows unexpected energy spikes during lunch breaks, supervisors can investigate whether equipment was left running unnecessarily. This visibility creates accountability and enables data-driven decisions rather than assumptions about energy use.

How can IoT automate energy control systems?

Manual energy management relies on human rememberance and consistency, which often fails due to production pressures and shifting priorities. Workers focused on meeting quotas may overlook energy-saving practices like turning off unused equipment.

IoT systems automate energy control through smart scheduling, occupancy-based operation, and optimized equipment sequencing that reduces consumption without compromising production output.

What automated control strategies deliver the best results?

Smart lighting systems with motion sensors ensure lights only operate in occupied areas, reducing electricity waste in warehouses and less-frequented production zones. Automated power management schedules non-essential equipment to power down during breaks and between shifts. For our sewing operations for fabric accessories, we implemented IoT-controlled machine sleep modes that activate after 15 minutes of inactivity, reducing idle energy consumption by 65% without impacting worker productivity.

How can IoT optimize manufacturing process sequencing?

IoT systems analyze production schedules and energy pricing data to sequence equipment operation for maximum efficiency. Energy-intensive processes like plastic injection for hair band production can be scheduled during off-peak electricity rate periods. The system can also stagger equipment startup to avoid demand charges from simultaneous high-power draws. This intelligent sequencing reduced our peak demand charges by 22% while maintaining the same production output.

How does IoT enable predictive maintenance for energy efficiency?

Equipment degradation silently increases energy consumption long before complete failure occurs. Worn bearings, dirty filters, and misaligned components force machines to work harder, consuming more energy for the same output.

IoT predictive maintenance detects these efficiency losses early by monitoring equipment performance indicators and scheduling maintenance only when needed, preventing both energy waste and unexpected downtime.

What IoT parameters indicate declining energy efficiency?

Vibration sensors detect misalignments and bearing wear in motor-driven equipment like looms for scarf production. Thermal imaging identifies overheating components that indicate friction or electrical resistance increases. Power quality analyzers detect phase imbalances and power factor issues that reduce electrical efficiency. By addressing these issues proactively, our textile printing equipment maintains optimal energy efficiency, using 18% less electricity than similar non-monitored machines.

How does predictive maintenance reduce energy waste?

Traditional maintenance schedules either waste resources on unnecessary servicing or allow equipment to degrade into inefficient operation. IoT-enabled predictive maintenance intervenes precisely when efficiency begins declining but before significant energy waste occurs. For example, our monitoring system detected abnormal energy patterns in our embroidery machines two weeks before visible performance issues emerged, allowing maintenance that prevented 240 hours of inefficient operation and 15% excess energy consumption.

How can IoT optimize HVAC and facility energy usage?

Heating, ventilation, and air conditioning often represent 40-60% of a manufacturing facility's energy consumption, yet most systems operate on fixed schedules without considering actual production needs or external conditions.

IoT creates dynamic HVAC control that responds to production schedules, occupancy patterns, weather conditions, and specific process requirements to minimize energy waste while maintaining optimal working conditions.

What IoT strategies optimize climate control energy usage?

Occupancy sensors adjust temperature setpoints in unused areas, while production scheduling integration ensures proper climate conditions are maintained only when needed. Weather forecasting integration pre-cools or pre-heats facilities based on expected conditions, reducing peak energy demands. In our accessory assembly areas, we implemented zone-based climate control that reduced HVAC energy usage by 31% while maintaining comfort in occupied workstations.

How can IoT manage ventilation based on actual needs?

Traditional ventilation systems often operate continuously regardless of air quality. IoT air quality sensors monitor CO2 levels, humidity, and particulate matter, adjusting ventilation rates to actual requirements. In areas like our leather processing for belts and bags, this demand-controlled ventilation reduced fan energy consumption by 45% while improving air quality through more precise control. The system also detects filter condition, indicating replacements only when needed rather than on fixed schedules.

Conclusion

IoT technology offers fashion accessory manufacturers a powerful toolkit for transforming energy management from periodic concern to continuous optimization. The combination of detailed monitoring, automated control, predictive maintenance, and facility optimization creates substantial cost savings while reducing environmental impact. As energy costs continue to rise and sustainability becomes increasingly important to consumers, these technologies provide competitive advantages beyond simple cost reduction.

Manufacturers who embrace IoT energy management position themselves as industry leaders in both efficiency and environmental responsibility, appealing to increasingly eco-conscious brands and consumers.

If you're interested in implementing IoT energy solutions for your accessory production or want to partner with a manufacturer committed to sustainable operations, we invite you to contact our Business Director, Elaine. She can discuss our energy optimization initiatives and how we're reducing environmental impact while maintaining competitive pricing. Reach her at: elaine@fumaoclothing.com.