You’ve finalized your design, approved your belt samples—and then the real challenge begins: sourcing at scale, getting it out of China, and clearing customs before your customer cancels their order.

Sourcing custom woven belts from China is about more than just selecting a factory—it’s about choosing the right region, balancing MOQ and lead times, optimizing shipping, and planning ahead for customs.

As the owner of AceAccessory, I’ve helped global brands—from retailers to distributors—source woven belts efficiently. This guide shares what I’ve learned through hundreds of successful exports.

Top Chinese Regions for Woven Belt Manufacturing?

Designs look good on paper, but quality comes down to where you produce—and who you partner with.

The top woven belt manufacturing hubs in China are Zhejiang, Fujian, and Guangdong. These regions offer advanced weaving infrastructure, experienced workers, and mature logistics.

Why location matters in sourcing

Just like how Italian suits come from Milan or Chinese silk from Suzhou, woven belt quality is often region-specific. The right location ensures material availability, skilled labor, and shorter lead times.

Breakdown of top regions:

| Region | Key City | Strengths |

|---|---|---|

| Zhejiang | Yiwu, Shaoxing | Large-scale woven tape factories, custom patterns |

| Fujian | Quanzhou | Affordable pricing, strong in sports/fashion belts |

| Guangdong | Guangzhou | Trend-sensitive, fast sampling, high-end materials |

We’ve based our factory in Zhejiang for a reason—it’s where we source strong webbing yarns, quality buckles, and fast weaving lines under one roof. Clients benefit from consistent quality and consolidated shipments.

Questions to ask your supplier:

- Where do you source your polyester or cotton yarn?

- Can I visit your weaving lines or dye house?

- What finish do you offer (e.g. silicone-wash, anti-fray)?

- Are your materials REACH or PROP 65 compliant?

MOQ and Lead Time for Custom Belt Orders?

You don’t want to overcommit your inventory. But you also don’t want to get stuck with high MOQs you can’t sell.

For custom woven belts in China, the typical MOQ ranges from 500 to 1,000 pieces per design, and lead time is about 15 to 30 days after sample approval.

Understanding the variables

Several things affect both MOQ and production lead time:

| Factor | MOQ Impact | Lead Time Impact |

|---|---|---|

| Custom yarn dyeing | Higher MOQ (min 20kg) | Adds 3–5 days |

| Printed logos on belts | MOQ > 1,000 | Adds setup and QC time |

| Custom hardware | Increases mold/setup | May extend to 30–35 days |

| Off-season production | Easier to lower MOQ | Faster turnaround possible |

Tips for small buyers:

- Use shared dye lots: We often batch multiple clients’ orders using standard Pantone yarns, reducing your MOQ.

- Start with stock materials: Choose from our in-house yarns, buckles, and widths to get 500 MOQ without customization.

- Pre-book your line: We let repeat clients reserve a weaving slot in advance, shortening delays.

At AceAccessory, we balance MOQ flexibility with quality assurance. Our clients can launch new designs without betting their whole budget on inventory.

Best Shipping Methods for Fast & Cost-Effective Delivery?

Even the best-made belts are useless if they’re stuck at port or delivered weeks late.

The best shipping method depends on your order volume and urgency. Air freight is fastest, while sea freight (LCL or FCL) is more cost-effective for bulk woven belt orders.

Shipping method comparison:

| Method | Delivery Time | Best For | Notes |

|---|---|---|---|

| Air Express | 5–8 days | Urgent samples, 20–100 belts | Higher cost, door-to-door |

| Air Cargo | 7–12 days | Launch orders < 500kg | Needs clearance agent on arrival |

| Sea (LCL) | 25–35 days | Small bulk 2–8 CBM | Consolidated, lower cost |

| Sea (FCL) | 28–40 days | Bulk orders > 10 CBM | Full control, lower per-unit shipping |

| Rail (EU only) | 15–25 days | To Europe, belts + other accessories | Greener than air, faster than sea |

Our advice:

If you're preparing for Black Friday, Spring drops, or gifting seasons, don’t leave logistics to chance.

We offer:

- Multi-port origin (Ningbo, Shanghai, Guangzhou)

- Pre-packing QC with weight declarations

- Partnered forwarders for LDP/DDU service

- Split shipping (air for samples, sea for bulk)

A well-packed woven belt order can avoid crushing, tangling, and miscounts—all while hitting the dock just in time.

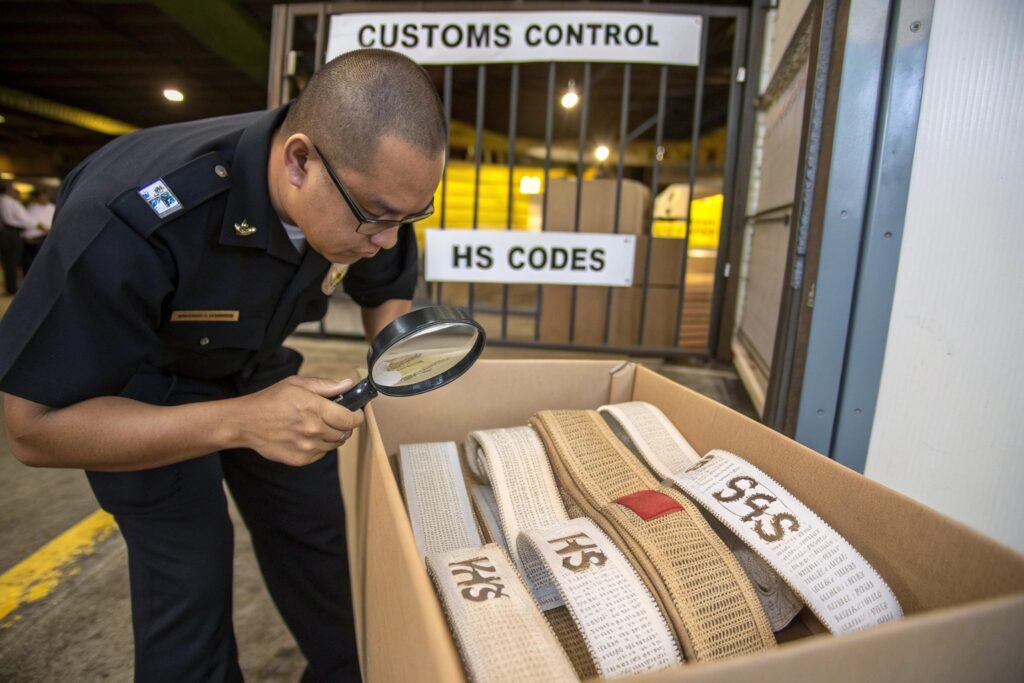

How to Ensure Smooth Customs Clearance for Belts?

Your belts are ready to go—but can they clear customs without delays or penalties?

To clear woven belts into the U.S. or EU smoothly, ensure correct HS codes, fiber labeling, and declaration of metal or leather components.

Common customs triggers for belts:

| Problem Type | Impact | Example |

|---|---|---|

| HS Code misclassification | Extra duties or reinspection | Declaring cotton belt as nylon |

| Missing fiber label | Fines or repacking | Skipping % breakdown label |

| Undeclared buckle metal | Delay or seizure | Zinc alloy marked as "plastic" |

| Leather parts | Require Lacey Act / CITES docs | PU vs. real leather confusion |

Our solution at AceAccessory:

- We provide correct HTS codes, based on fiber content and use (e.g., fashion vs. work belts).

- All belts are shipped with fiber composition tags and packaging markings.

- We assist in preparing US Lacey Act or EU REACH compliance statements.

- Our packaging team includes customs-friendly invoice templates and weight declarations for every master carton.

By treating customs as part of the product journey—not an afterthought—we help clients avoid surprise fees, port hold-ups, or destroyed shipments.

Conclusion

Sourcing custom woven belts from China is only efficient when you combine design, production, shipping, and customs strategies into one workflow. At AceAccessory, that’s what we deliver: woven belt manufacturing with real-world logistics solutions—designed for global success.