When sourcing accessories that involve UV printing and complex shipping logistics, buyers often face a maze of technical and operational challenges. From choosing the right supplier to ensuring the quality of printed designs, every step requires attention to detail. Add international freight, customs clearance, and delivery timelines into the mix, and the complexity grows even further.

The key is preparation. By understanding the UV printing process, supplier evaluation, and efficient shipping strategies, you can avoid costly mistakes. Many importers from the US and Europe have increased their profits simply by choosing the right partners in China with strong production capacity and logistics support.

When you work with an experienced manufacturer like ours, the entire journey—from product design to final delivery—is smoother and faster. Let’s break down the process into practical steps that ensure quality, timeliness, and cost-efficiency.

Understanding UV Printing for Accessories

UV printing is a game changer in accessory customization. It allows designs to be printed directly onto the surface of various materials—plastic, fabric, leather—without requiring labels or transfers. The result is vibrant, durable prints that resist fading and scratching.

The advantage of UV printing is speed and flexibility. It is ideal for short production runs or seasonal collections. Brands no longer need to invest in massive inventories. They can test new designs in small batches, receive them quickly, and respond to market trends in real time.

How does UV printing improve product quality?

UV printing uses ultraviolet light to cure ink instantly, creating a sharper and more durable finish than traditional printing. The process works on flat and curved surfaces, enabling intricate details on items like custom printed belts or UV-printed hats. This flexibility makes it perfect for brands looking to differentiate their collections.

Why is UV printing ideal for small batch orders?

With UV printing, setup time is minimal compared to screen printing or embroidery. This means even small runs can be done cost-effectively. Many buyers prefer this for promotional products or seasonal accessory lines that don’t justify large-scale production. It helps manage inventory risk while still delivering unique, high-quality products.

Finding the Right UV Printing Accessory Supplier

Choosing the right supplier goes beyond price comparison. A reliable factory must have both the equipment and the expertise to meet your quality and delivery requirements. This is especially true for UV printing, where technical skill directly impacts the final product.

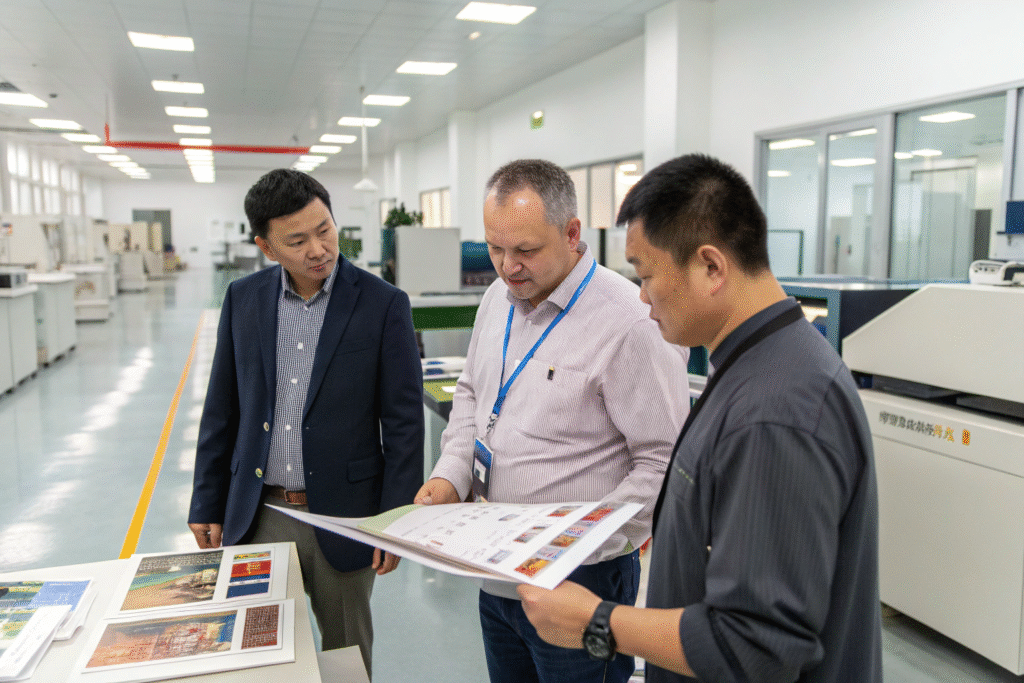

We recommend visiting trade shows, browsing verified supplier profiles online, and requesting samples. A professional factory will provide detailed specifications, testing reports, and clear communication about production capacity.

What certifications should a supplier have?

Look for suppliers with ISO 9001 certification for quality management and REACH compliance for chemical safety. These certifications ensure that the accessories are safe for consumers and that the production process is well-controlled.

How to verify a supplier’s UV printing capability?

Request a sample print test on your actual product materials. Many buyers skip this step and regret it later. You can also ask for a virtual factory tour or visit the facility in person to see their printing machines and quality control systems in action.

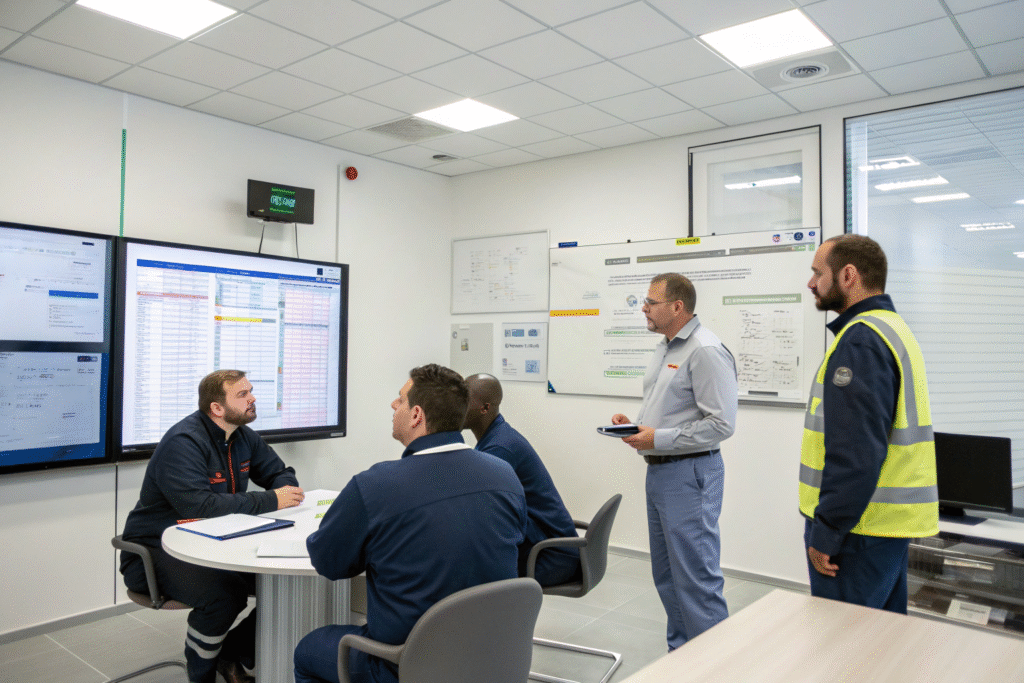

Managing International Shipping for Accessories

Shipping accessories from China to the US or Europe involves multiple steps—factory dispatch, port handling, customs clearance, and last-mile delivery. Each stage requires coordination to avoid delays.

Working with a manufacturer that also manages logistics can save you time and reduce costs. They can advise on the best shipping methods—air freight for urgent orders, sea freight for bulk shipments—and provide accurate timelines.

Which shipping method is best for UV-printed accessories?

For small, urgent batches, air freight is the fastest. Companies like DHL Express offer delivery in under a week. For larger, cost-sensitive orders, sea freight via Maersk can save significantly, though it takes 25–35 days.

How to avoid customs delays and extra tariffs?

Partner with a supplier who understands your target market’s regulations. For the US, Section 321 entry can exempt low-value shipments from tariffs. Your supplier should also provide accurate HS codes to avoid misclassification.

Reducing Costs and Lead Times in Accessory Sourcing

The right sourcing strategy can significantly cut costs while speeding up production. Factors such as batch size, material choice, and shipping method all affect the bottom line.

Negotiating terms early and maintaining open communication with your supplier is key. Many buyers gain discounts by consolidating shipments or scheduling production during low-demand seasons.

What are effective ways to lower UV printing costs?

One method is to use standardized accessory bases—like plain hats or belts—and only customize the print. This reduces setup costs. Also, working with suppliers who buy materials in bulk, such as wholesale accessory suppliers, can lower your per-unit price.

How can lead times be shortened without sacrificing quality?

Pre-booking production slots and choosing faster curing inks can help. Some factories use automated UV printers that can print multiple items at once, reducing production days. Good planning with your supplier is essential to avoid last-minute rush fees.

Conclusion

Sourcing accessories with UV printing and managing their shipping logistics requires a blend of technical knowledge and operational planning. By working with experienced manufacturers who offer both printing and logistics services, you can ensure consistent quality, timely deliveries, and competitive pricing.

If you are looking to produce your own line of UV-printed accessories, we at Shanghai Fumao can help. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your project and receive a tailored sourcing plan.