When buyers in the United States or Europe look for accessories manufacturers in China, they often face the same problem. They want suppliers who can handle custom closures like buckles, snaps, zippers, or Velcro, but many factories are slow in development, limited in options, and weak in quality control. This causes delays, price inefficiency, and missed opportunities in retail seasons.

The good news is that sourcing accessories with custom closures and fastening systems is possible if you know how to identify the right partners. By focusing on quality, design flexibility, and supply chain reliability, brands can find Chinese manufacturers that deliver on speed, cost, and innovation.

That is why in this article, I want to explain how to source fashion accessories with advanced fastening options. I will also share how we at AceAccessory in Zhejiang Province provide solutions that meet the expectations of big retailers, department stores, and online sellers worldwide.

What are the Most Popular Closure Types in Accessories?

When sourcing accessories, most buyers care about which closure types are available and how they affect both design and practicality. Customers in North America and Europe expect not only fashion but also reliability in wear and daily use.

The most popular closure systems for accessories today include zippers, magnetic snaps, hook-and-loop (Velcro), buttons, and buckles. Each closure offers unique benefits in style, durability, and function, and understanding these can help buyers choose the right solution for their market.

Why Are Zippers and Snaps Still Leading Choices?

Zippers and snaps dominate because they are versatile and reliable. High-quality zippers from suppliers like YKK ensure smooth operation and long-term durability. Snaps, whether metal or plastic, are widely used in hats, belts, and bags for their ease of use. Many U.S. and European buyers request these because they balance cost efficiency with a polished look. For functional outdoor products, snaps paired with weather-resistant materials are particularly popular.

Are Magnetic Closures and Velcro Becoming More Trendy?

Yes, especially in lifestyle and children’s products. Magnetic closures, available from brands like MagSnap, are elegant and quick to use. Velcro, while sometimes considered casual, is still a major option for sports caps, gloves, and even belts. Customers value these options because they allow fast production and meet demand in fast-fashion cycles. For sourcing, it is key to find factories that can integrate these closures seamlessly into accessories without compromising quality.

How to Ensure Quality in Custom Fastening Systems?

Every buyer fears receiving accessories with weak closures that break during retail sales. This not only damages brand trust but also causes heavy losses in logistics and returns.

Ensuring quality in fastening systems starts with raw materials, continues through testing and certification, and ends with final inspection before shipping. Buyers must work with factories that have strong QC teams and can provide reliable documentation.

What Role Does Material Certification Play?

Material certification is a critical step. For example, international buyers often request OEKO-TEX certification to guarantee fabric safety. When it comes to metal fasteners, SGS Testing ensures they meet safety and durability standards. Buyers who partner with factories that understand these requirements gain confidence that their closures will last and pass customs inspections without issues.

How Important is In-House Quality Control?

It is essential. At AceAccessory, we have a dedicated QC team that checks each production batch. We test buckles, zippers, and Velcro for strength, durability, and smoothness. Buyers can also request third-party inspection through services like Intertek. This provides transparency and helps clients avoid unnecessary risk. Having these systems in place means fast problem solving, less waste, and on-time deliveries.

Why is Fast Development Capacity Critical for Buyers?

Global buyers, especially in fashion retail, work with strict seasonal calendars. If a factory is slow in sampling or cannot adjust closure designs quickly, the buyer risks missing the launch date.

Fast development capacity is critical because it allows brands to test new markets, meet fashion trends, and react to consumer demand without delay.

How Can Prototyping Speed Up the Process?

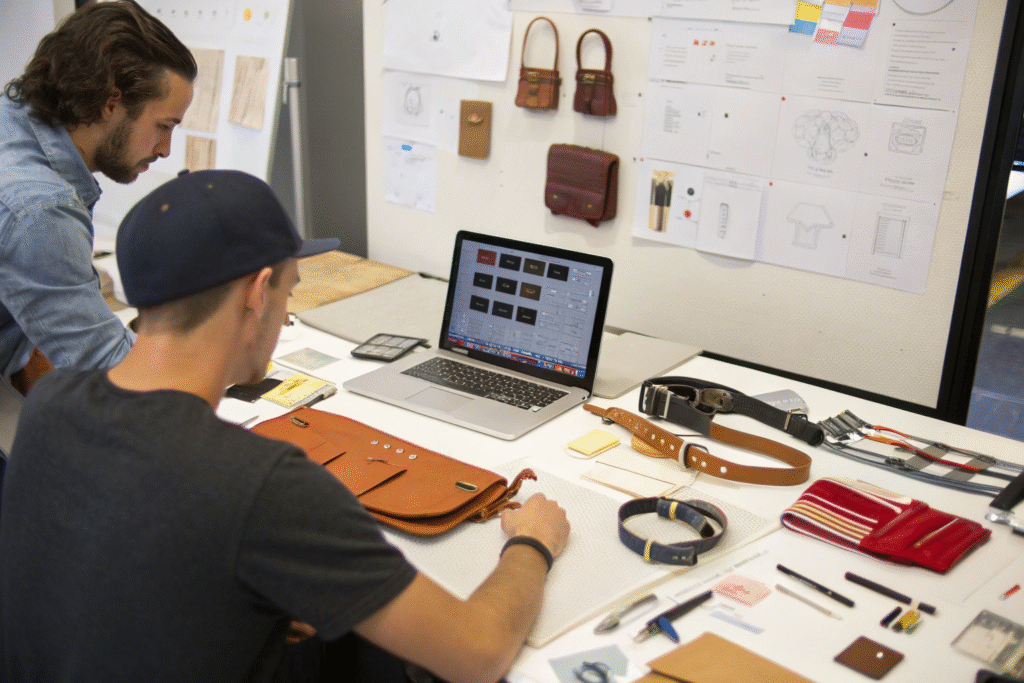

Prototyping shortens the communication gap. Using CAD software and sample machines, factories can produce functional prototypes within days. For example, platforms like CLO 3D help visualize accessories with different closure systems. Buyers who source from factories with these tools avoid long back-and-forth emails. They see the product quickly and make adjustments before bulk production starts.

Does Customization Affect Lead Time?

Customization can add time, but with the right supplier, delays are minimal. For example, a belt with a unique buckle design can be prototyped within 7–10 days if the factory has in-house mold-making. Suppliers without such capability may take 3–4 weeks, losing valuable market time. Working with manufacturers who invest in fast mold and sample development ensures timely delivery to markets like the U.S. or Europe, where seasons change quickly.

What Logistics Solutions Help Avoid Delays and Tariff Risks?

Even if closures and fastenings are perfect, logistics can ruin a deal. Buyers worry about shipping delays, rising tariffs, and customs risks. A strong sourcing plan includes reliable logistics support.

The best factories provide integrated logistics solutions that cover packaging, customs clearance, and tariff-friendly routing. By doing so, they save buyers time, reduce cost, and prevent stress.

Can Factories Help with Customs and Tariff Management?

Yes. Many Chinese manufacturers work with logistics partners to manage customs paperwork. Some even ship under HS codes that are not affected by U.S. tariffs, giving buyers a clear advantage. Resources like U.S. Customs and Border Protection provide guidelines, but having a supplier who already understands how to apply them saves time.

How Important is Flexible Shipping for Retail Buyers?

It is very important. For fast-fashion retailers, shipping by air is sometimes necessary. For big-box stores, sea freight is the best option. Companies like Maersk offer flexible solutions that can be adapted based on budget and timeline. Buyers who partner with factories that provide flexible shipping options avoid unnecessary bottlenecks. This ensures accessories with custom closures arrive on time and within budget.

Conclusion

Sourcing accessories with custom closures and fastening systems does not have to be difficult. Buyers who understand closure types, insist on quality control, and demand fast development will succeed in working with the right partners. Logistics planning and tariff management add another layer of protection.

At AceAccessory in Zhejiang, we combine strong design teams, experienced project managers, and professional QC systems to deliver accessories that meet global standards. Whether you need belts, hats, scarves, or bags with custom zippers, snaps, or buckles, we are ready to support your brand. To start your project, contact our Business Director Elaine at elaine@fumaoclothing.com and explore how we can produce your next successful accessory collection.