Baseball caps are lightweight—but they can lose shape or get crushed during shipping if packed incorrectly.

To ship baseball caps without damage, use firm boxes, cap inserts, and careful stacking to prevent crushing or deformation during transit.

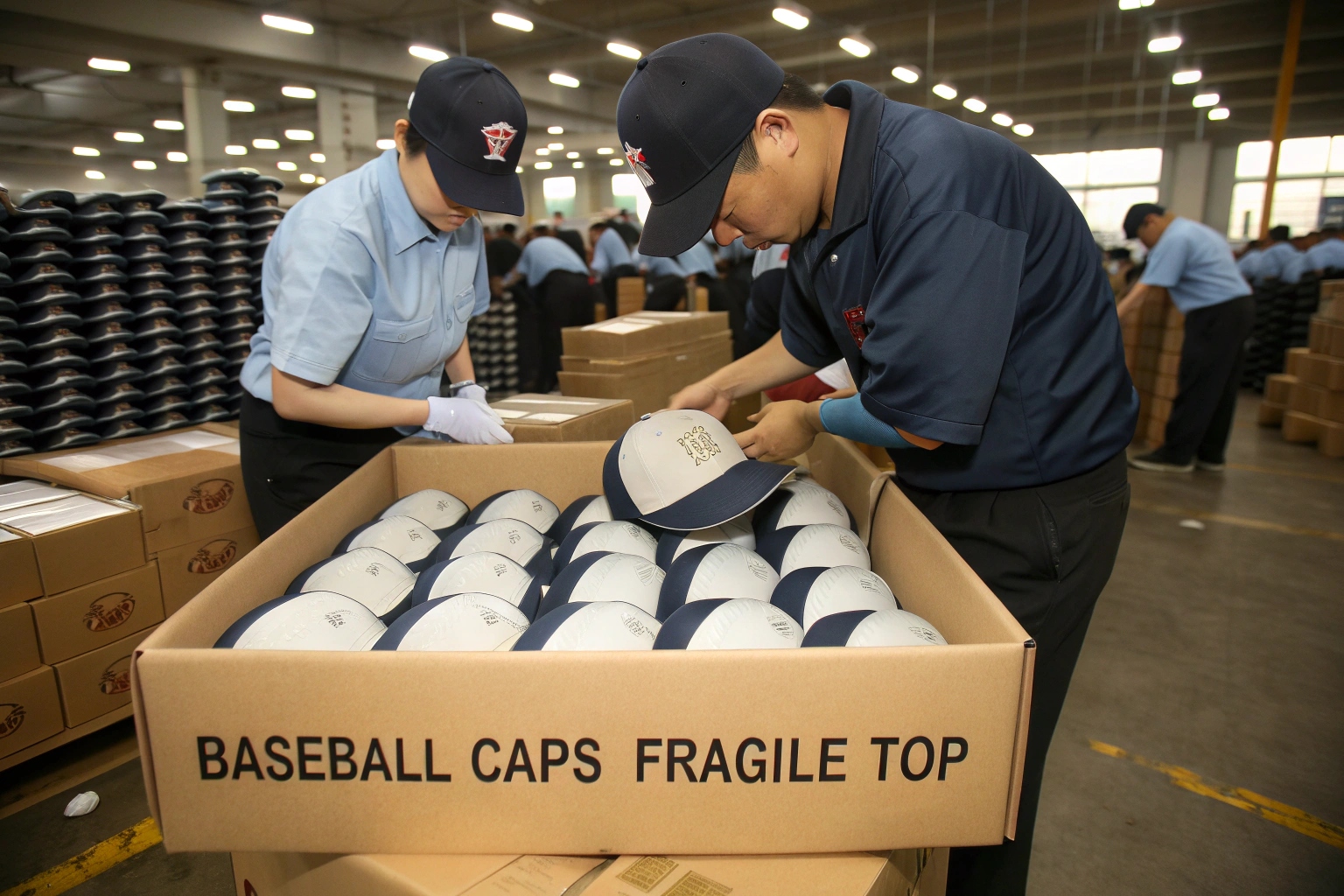

As the owner of AceAccessory, I’ve helped many U.S. and European clients receive bulk shipments of hats in perfect condition. In this article, I’ll explain our proven packing and shipping strategies—whether you’re sending one piece or one thousand.

What's the best way to ship a baseball hat?

Baseball hats can easily bend, flatten, or lose structure if you pack them like regular garments.

The best way to ship a baseball hat is to use structured packaging—rigid boxes, crown fillers, and tight stacking—to protect shape and form.

How do we protect cap structure when shipping in bulk from China?

At AceAccessory, we’ve shipped tens of thousands of caps overseas—from cotton dad hats to structured 6-panel promo caps. What we’ve learned is simple: the brim and crown need form protection. Here’s what we do:

- Insert foam domes or cardboard cups inside each cap to hold the crown upright.

- Stack hats nested inside each other—carefully, and usually in stacks of 12 to 24.

- Place the entire stack in firm double-wall cartons with at least 1.5" of padding on all sides.

- Use dividers for multiple stacks to avoid movement during transit.

For higher-end hats with embroidery, metal logos, or firm front panels, we use vacuum-formed plastic molds for added shape integrity.

If you're shipping hats via sea freight, the added pressure from container stacking requires even more care. We ship pallets with corner guards, shrink-wrap them tight, and use moisture-proof liners inside each carton—because ocean containers can sweat.

| Shipping Type | Recommended Packaging | Damage Risk | Notes |

|---|---|---|---|

| Small Parcel | Box with single cap insert | Low | Ideal for DTC / e-com |

| Air Freight | Stacked with crown fillers | Medium | Balance weight and volume |

| Sea Freight | Nested stacks, firm cartons, wrap | Low | Best for bulk import orders |

No matter the method, structure and protection are more important than volume. Damaged hats are unsellable—especially if you're delivering to retail stores or brand partners.

What are the cost implications of using professional packaging vs. standard packing?

Good question. Some importers want to cut packaging cost—but cheaping out on hat packaging can cost more in losses. Here's an example we saw with one client:

| Packaging Type | Per Cap Cost | Delivery Damage Rate | Return Rate | Overall Loss |

|---|---|---|---|---|

| Polybag Only | $0.02 | 18% | 12% | High |

| Box + Foam Insert | $0.18 | 1.2% | 0.6% | Very Low |

The better option saved them thousands by protecting brand image and avoiding refunds. Smart buyers consider total landed cost—not just shipping fees.

How do I send a cap in the post?

Sending a single cap sounds easy—but many arrive crushed or bent because of poor packaging.

To mail a cap safely, place it in a firm box with crown support and fill empty space to stop movement. Never use a soft mailer.

What’s the ideal box type for sending a single cap to the U.S.?

If you’re selling caps DTC (direct to consumer) or shipping samples to partners, the right box matters. We recommend:

- Box size: 7" x 7" x 5" (or close)

- Material: Corrugated cardboard, 32 ECT or better

- Interior: Foam dome or air pillow inside crown + kraft filler paper

- Label: Flat on top, avoid folding over side seams

You can even brand the box with your logo. We do this for brands that want a luxury unboxing feel.

If you're dropshipping, we can pack each cap in branded boxes with barcode and SKU stickers for your 3PL.

| Cap Type | Suggested Box Size | Cushioning Needed | Typical Weight |

|---|---|---|---|

| Dad Hat | 7" x 7" x 5" | Light | 120–140g |

| Flat Brim | 8" x 8" x 6" | Medium | 180–200g |

| Foam Trucker | 8" x 10" x 6" | High | 160–190g |

Avoid mailer bags unless you're shipping ultra-soft fabric hats with no form. Customers expect clean, firm shapes—especially if sold on Amazon or Shopify.

Can I use envelope mailers or padded bags to send baseball caps?

In short: you can—but you shouldn't. While a bubble envelope might protect soft brims, any structured cap will get squashed flat during transit.

We’ve tested it. When mailing test samples to U.S. clients using soft mailers, the return rate jumped 15%. Using boxes brought that down to under 1%.

Your brand experience is part of the value. Boxed caps show care, and protect the unboxing moment.

What size box to ship a baseball hat?

Shipping box size matters. Too small, and the hat gets crushed. Too big, and you waste volume and pay higher dimensional weight.

A 7" x 7" x 5" box is ideal for most baseball caps, allowing secure placement without movement or pressure.

How do we calculate the best box size for caps based on shape and material?

At AceAccessory, we size boxes based on:

- Crown height

- Brim stiffness

- Material compressibility

- Quantity per shipment

Let’s break it down:

| Cap Type | Crown Height | Brim Type | Box Size (Per Cap) |

|---|---|---|---|

| Soft Cotton | 4.5" | Curved, soft | 7" x 7" x 5" |

| Trucker Mesh | 5" | Curved, foam | 8" x 8" x 6" |

| Snapback | 5.5" | Flat, stiff | 8" x 10" x 6" |

| Fitted Hat | 5" | Flat/curved | 8" x 8" x 6" |

For bulk shipments, we use boxes like 22" x 18" x 16" to stack 48–60 caps securely. Every box includes stacking guides and side labels for U.S. warehouse scanning.

Should I choose box size based on carrier pricing or cap size?

Both. If you're shipping single caps via FedEx or UPS, make sure the box is under the carrier’s dimensional pricing threshold. But never sacrifice structure for size.

For example, USPS charges based on "DIM weight" after 1 cubic foot. Our 7x7x5 box is under that, and avoids oversized fees.

In contrast, squeezing a hat into a 6x6x4 box might reduce cost by $0.20—but causes 5x more returns. Not worth it.

How much does a baseball cap weigh?

Weight affects not just shipping cost—but also how many caps you can pack per carton or pallet.

Most baseball caps weigh between 120g and 200g depending on material, design, and accessories.

What factors affect a cap’s shipping weight and packaging strategy?

The cap’s weight varies based on:

- Fabric type (cotton, mesh, wool, etc.)

- Lining or underbrim features

- Closure hardware (metal buckle vs. plastic snap)

- Decorations (embroidery, patches, rhinestones)

Here’s a quick guide:

| Cap Type | Material | Typical Weight |

|---|---|---|

| Cotton Dad Hat | Cotton twill | 120–130g |

| Trucker Hat | Polyester + foam | 160–180g |

| Snapback | Wool blend | 180–200g |

| Luxury Branded | Heavy cotton + logo | 210–240g |

We weigh each cap during final QC and update our packing lists accordingly. For air freight, every 10g matters. It affects your total landed cost, especially when shipping hundreds of units.

How does cap weight affect international freight choices?

Heavier caps mean higher air shipping cost. That’s why many clients choose sea freight for large orders, even if it takes longer.

If you're shipping 5000 caps at 160g each, that’s 800kg—not counting cartons and pallets. Here’s a comparison:

| Mode | Lead Time | Cost (per kg) | Notes |

|---|---|---|---|

| Express Air | 5–7 days | $6–9 | Best for small runs or samples |

| Air Freight | 8–12 days | $3–5 | Better for 300kg+ |

| Sea Freight | 22–35 days | $0.5–1.2 | Best for 500kg+ |

We help clients choose the best mix. Some ship 200 caps by air for urgent launch, and the rest by sea. We label and split the inventory as needed—so you stay agile.

Conclusion

Baseball caps are simple in design—but hard to ship well without care. Whether you’re a brand buyer or an importer, you want every hat to arrive ready for retail. At AceAccessory, we offer professional packaging, QC, and shipping that guarantees shape and quality—every time.