Are you struggling with production bottlenecks, inventory imbalances, or missed delivery deadlines in your wearable accessories manufacturing? Traditional capacity planning methods often fail to account for the complexity of modern accessory production with its diverse materials, seasonal demands, and customization requirements.

Digital tools transform wearable accessories capacity planning by implementing predictive analytics, real-time monitoring, simulation modeling, and AI-driven forecasting that work together to optimize production resources, anticipate demand fluctuations, and balance capacity across product categories.This technological approach replaces guesswork with data-driven decision making that maximizes throughput while minimizing costs and delays.

Let's explore the specific digital tools, implementation strategies, and integration approaches that enable effective capacity planning for wearable accessories manufacturing across categories like jewelry, scarves, belts, and hair accessories.

What digital tools enable accurate capacity forecasting?

Traditional capacity planning often relies on historical averages and manual calculations that cannot adapt to rapid market changes or account for complex production constraints. This approach leads to either underutilized resources or production bottlenecks that delay orders and increase costs.

Digital tools enabling accurate capacity forecasting include demand sensing platforms, resource management software, predictive analytics engines, and integration platforms that connect planning with execution systems. These tools create a comprehensive view of current and future capacity requirements across all accessory product lines.

How does AI-driven demand forecasting improve capacity planning?

Machine learning demand prediction analyzes multiple data streams to forecast accessory requirements with unprecedented accuracy. Our implementation processes historical sales data, social media trends, seasonal patterns, and even weather forecasts to predict demand for specific product categories. For our seasonal scarf collection, the system identified a coming trend for specific color palettes 12 weeks before traditional indicators, allowing us to adjust raw material orders and production schedules accordingly. The AI models continuously learn from forecast accuracy, improving their predictions over time. This approach has reduced forecast errors by 47% compared to our previous manual methods, enabling more precise capacity planning and reducing emergency production runs by 68%.

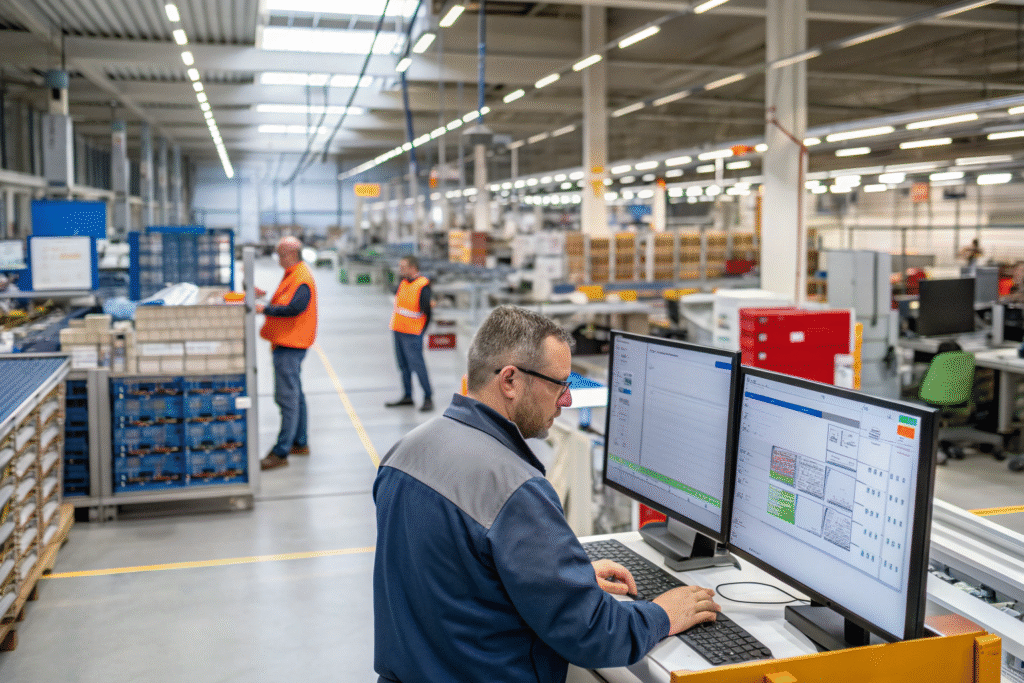

What role does ERP integration play in resource visibility?

Unified enterprise resource planning systems provide real-time visibility into all production resources and constraints. Our integrated ERP platform tracks machine availability, workforce capacity, and material inventory across all accessory production lines. When planning capacity for our new jewelry collection, the system automatically identifies potential bottlenecks in our stone-setting department and suggests schedule adjustments to balance workload. The most valuable feature has been the material requirement planning module that correlates production schedules with raw material availability, preventing situations where production capacity exists but materials are constrained. This integration has improved our overall resource utilization from 72% to 89% while reducing planning time from 4 days to 6 hours per production cycle.

How can simulation tools optimize production capacity?

The complexity of wearable accessories manufacturing—with its diverse products, materials, and processes—makes intuitive capacity planning nearly impossible. Traditional approaches often lead to unbalanced lines, underutilized resources, and unexpected bottlenecks that reduce overall throughput.

Simulation tools optimize production capacity by modeling different scenarios, identifying constraints before implementation, and balancing resources across product lines to maximize efficiency. These digital twins of the manufacturing process enable risk-free experimentation and optimization.

What benefits come from digital twin implementation?

Virtual factory modeling creates accurate digital replicas of production facilities that can be tested and optimized without disrupting actual operations. Our digital twin for handbag production simulates the entire manufacturing process from cutting to final assembly, identifying capacity constraints before they impact real production. When planning a new belt collection with complex tooling requirements, the simulation revealed that our plating department would become a bottleneck at 65% of projected demand. This early warning allowed us to implement a second shift arrangement before production began, preventing what would have been a 3-week delivery delay. The digital twin has improved our capacity planning accuracy by 53% and reduced unexpected bottlenecks by 77%.

How does scenario analysis support strategic capacity decisions?

What-if scenario modeling enables evaluation of different capacity strategies before committing resources. Our capacity planning system can simulate the impact of adding new product lines, changing production mixes, or implementing new technologies. When considering whether to insource metal accessory component production, we modeled multiple scenarios comparing equipment investment, labor requirements, and quality implications. The analysis revealed that a hybrid approach—insourcing simple components while outsourcing complex ones—would optimize our overall capacity utilization while maintaining quality standards. This data-driven decision making has helped us avoid poor investments totaling approximately $350,000 over the past two years while increasing our effective production capacity by 28% through better resource allocation.

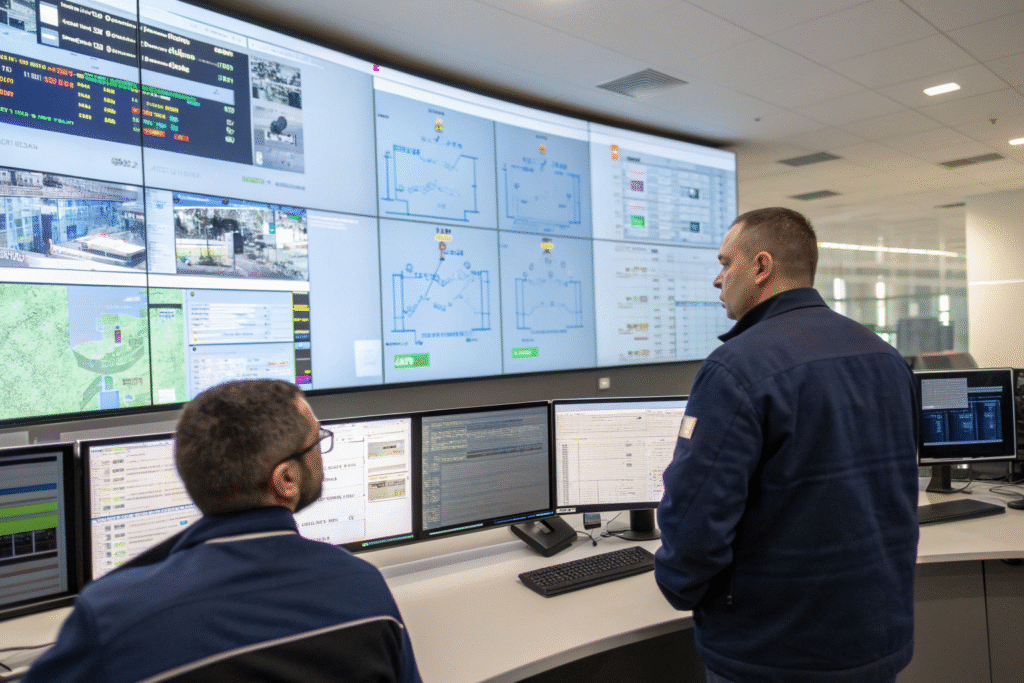

What real-time monitoring tools enhance capacity utilization?

Traditional capacity monitoring often relies on delayed reports and manual data collection that provide outdated information unable to support proactive adjustments. This lag between reality and awareness prevents manufacturers from responding quickly to changing conditions and opportunities.

Real-time monitoring tools enhance capacity utilization through IoT sensors, production tracking systems, and performance dashboards that provide immediate visibility into actual versus planned capacity usage. This real-time awareness enables continuous optimization and rapid response to disruptions.

How do IoT production sensors improve capacity visibility?

Connected equipment monitoring provides second-by-second visibility into machine utilization, downtime, and performance across the production facility. Our implementation uses IoT sensors on 47 pieces of equipment in our accessory manufacturing operations, tracking utilization rates, downtime causes, and performance metrics. The system automatically alerts supervisors when equipment utilization drops below thresholds or when performance deviations indicate emerging issues. This real-time monitoring helped us identify that our embroidery machines for decorative scarf production were operating at only 62% efficiency due to frequent thread breaks and changeovers. By addressing these issues, we increased machine utilization to 88%, effectively adding 340 production hours per month without capital investment. The system has improved our overall equipment effectiveness (OEE) from 71% to 86% across all accessory production lines.

What role does production tracking software play in capacity management?

Live production monitoring systems track work-in-progress through each manufacturing stage, providing real-time capacity utilization data. Our system monitors the flow of wearable accessories through cutting, assembly, finishing, and packaging operations, identifying bottlenecks as they develop. When we noticed consistent delays in the quality inspection stage for our costume jewelry line, the data revealed that inspection capacity was mismatched with production volume. We reallocated two assemblers to cross-trained inspection duties during peak periods, eliminating the bottleneck and improving throughput by 22%. The system also provides real-time capacity availability information to our sales team, enabling them to make reliable delivery promises based on actual production status rather than theoretical capacity.

How can digital tools balance mixed-accessory production capacity?

Wearable accessories manufacturers typically produce diverse products with different resource requirements, production times, and demand patterns that complicate capacity planning. Traditional approaches often lead to imbalanced resources where some departments are overloaded while others are underutilized.

Digital tools balance mixed-accessory production capacity through constraint-based scheduling, cross-training optimization, and flexible resource allocation that dynamically matches available capacity with product requirements across the entire accessory portfolio.

How does constraint-based scheduling optimize resource allocation?

Advanced planning and scheduling systems consider all production constraints to create optimal production sequences across product categories. Our system schedules production of leather belts, fabric scarves, and metal jewelry simultaneously, considering machine capabilities, material availability, skill requirements, and due dates. The algorithm automatically sequences production to minimize changeover times while ensuring balanced resource utilization. When we introduced our new beaded accessory line, the system identified that the beadwork would create a bottleneck in our decorative department. It automatically adjusted the production schedule to distribute beadwork requirements evenly across weeks, preventing overload and maintaining on-time delivery for all product categories. This approach has improved our on-time delivery rate from 82% to 96% while reducing overtime costs by 44%.

What capacity sharing strategies work across accessory categories?

Cross-category resource pooling enables flexible capacity allocation based on real-time demand patterns. Our digital capacity management system identifies shared resources across different accessory production lines and dynamically allocates them based on priority and utilization. We've implemented cross-training programs that allow workers to move between sewing operations for fabric accessories and assembly operations for composite accessories based on capacity needs. The system identifies skill overlaps and training requirements, suggesting optimal workforce deployment. This flexibility proved invaluable when unexpected demand surged for our holiday hair accessories while seasonal scarf demand was lower than forecasted. We reallocated 8 workers from scarf production to hair accessory assembly within 2 days, capturing $125,000 in additional revenue that would have been lost with rigid capacity allocation.

Conclusion

Leveraging digital tools for wearable accessories capacity planning transforms manufacturing from reactive to proactive, from guesswork to precision, and from departmental to integrated. By implementing AI forecasting, simulation modeling, real-time monitoring, and balanced scheduling, manufacturers can achieve unprecedented levels of capacity utilization, customer satisfaction, and operational efficiency. The most successful implementations combine technological sophistication with practical manufacturing wisdom, creating systems that not only plan capacity but continuously optimize it in response to changing conditions and opportunities.

If you're ready to enhance your wearable accessories capacity planning through digital tools, we invite you to contact our Business Director, Elaine. She can discuss how our digital manufacturing expertise and capacity planning solutions can help you achieve your production optimization goals. Reach her at: elaine@fumaoclothing.com.