Are you constantly facing inventory shortages or overstock situations with your shawl collections? The seasonal nature of shawl demand and fluctuating fashion trends make traditional supply chain methods inadequate. These challenges lead to lost sales, markdowns, and operational inefficiencies that impact your profitability.

Predictive supply chain management for shawls utilizes advanced analytics, machine learning algorithms, and real-time data integration to forecast demand accurately, optimize inventory levels, and proactively address potential disruptions before they impact your business. This data-driven approach transforms how you manage shawl production, distribution, and inventory across seasonal peaks and changing consumer preferences.

Let's explore the practical steps to implement a predictive supply chain system specifically designed for shawl manufacturing and distribution.

What data sources are needed for accurate shawl demand forecasting?

Many shawl businesses rely on historical sales data alone, missing crucial market signals that affect demand. This limited approach often results in inaccurate forecasts, especially for seasonal items and trend-driven designs.

Accurate shawl demand forecasting requires integrating multiple data sources including historical sales patterns, weather data, social media trends, economic indicators, and competitor activities. This comprehensive data integration creates a holistic view of market dynamics that drives more reliable predictions.

How does weather data improve seasonal shawl predictions?

Weather pattern analysis significantly enhances seasonal shawl demand forecasting, particularly for transitional periods and regional climate variations. Our predictive systems integrate historical weather data and meteorological forecasts to anticipate demand spikes for specific shawl materials and weights. For example, unexpected cold snaps in early fall can trigger immediate demand for warmer wool shawls, while unseasonably warm winters may increase interest in lighter linen wraps. By correlating temperature trends, precipitation patterns, and regional climate data with sales performance, we can adjust production schedules and inventory distribution before weather-driven demand materializes.

Why integrate social media trends into inventory planning?

Social media analytics provide early indicators of emerging shawl trends, color preferences, and style directions that traditional sales data cannot capture. Our systems monitor platforms like Instagram, Pinterest, and fashion blogs to detect rising interest in specific patterns, materials, or design elements. When we notice increasing engagement with bohemian-style fringed shawls or certain color combinations, we can adjust production priorities and raw material purchases accordingly. This proactive approach allows us to have trending items in production before peak demand, ensuring your collections align with current consumer preferences and maximizing sales opportunities.

How to set up inventory optimization for seasonal shawl demand?

Maintaining optimal inventory levels for seasonal shawl collections presents significant challenges. Overstocking ties up capital and leads to markdowns, while understocking results in lost sales and dissatisfied customers during peak demand periods.

Inventory optimization for seasonal shawl demand involves implementing dynamic safety stock calculations, establishing multi-echelon inventory distribution, and creating responsive replenishment triggers. These systems work together to ensure the right shawls are in the right locations at the right time throughout the demand cycle.

What is dynamic safety stock modeling for shawls?

Dynamic safety stock modeling continuously adjusts buffer inventory levels based on changing demand patterns, supply lead times, and service level targets. Unlike static safety stock approaches, our system recalculates optimal levels weekly using latest demand data, supplier performance metrics, and upcoming promotion plans. For cashmere shawls with longer production lead times, we maintain higher safety stocks during peak season, while for faster-turnaround acrylic blends, we optimize for leaner inventory. This approach typically reduces overall inventory carrying costs by 20-30% while improving in-stock rates to 98% during critical selling periods.

How does multi-echelon distribution optimize shawl availability?

Multi-echelon inventory distribution creates a hierarchical system where shawls are strategically positioned across central warehouses, regional distribution centers, and retail locations based on demand patterns and service requirements. Our predictive system determines optimal stock levels at each node, ensuring popular evening wrap styles are adequately distributed before holiday seasons while managing slower-moving designer shawls through centralized locations. This approach minimizes total system inventory while maintaining high service levels, reducing logistics costs, and improving overall supply chain responsiveness to regional demand variations.

What technology infrastructure supports predictive shawl supply chains?

Many businesses struggle with outdated systems that cannot handle the data processing requirements of predictive supply chain management. Legacy systems often operate in silos, preventing the integrated view needed for accurate predictions.

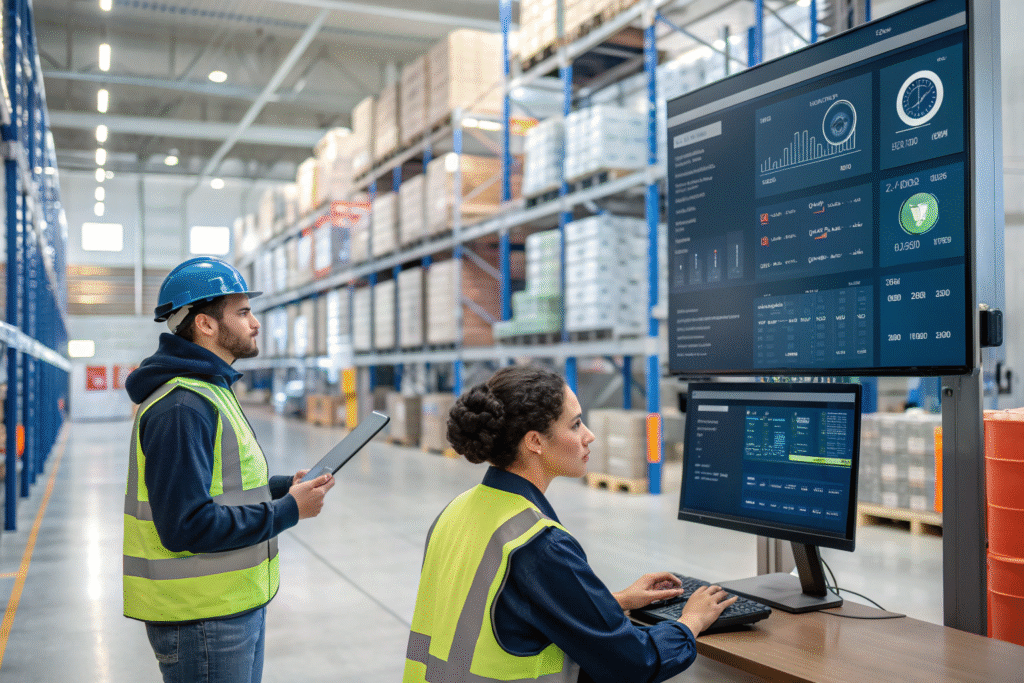

A robust technology infrastructure for predictive shawl supply chains requires cloud-based platforms, IoT sensors, API integrations, and advanced analytics capabilities. These technologies work together to collect, process, and analyze data from multiple sources in near real-time.

How do cloud platforms enable real-time shawl supply chain visibility?

Cloud-based supply chain platforms provide the foundation for real-time visibility across the entire shawl production and distribution network. Our implemented system connects raw material suppliers, manufacturing facilities, logistics partners, and distribution centers on a single platform. This enables continuous monitoring of shawl production status, inventory movements, and potential disruptions. When delays occur in embroidery material shipments or customs clearance, the system automatically alerts relevant stakeholders and suggests alternative actions. The cloud infrastructure ensures all parties access the same updated information, facilitating collaborative problem-solving and faster decision-making.

What role do IoT sensors play in shawl inventory management?

IoT sensor technology transforms physical inventory management by providing real-time visibility into stock levels, location tracking, and environmental conditions. Our warehouses utilize smart shelves with weight sensors that automatically update inventory counts as printed shawls are picked or replenished. GPS trackers monitor shipments in transit, while environmental sensors ensure proper storage conditions for delicate materials like silk shawls. This continuous data stream feeds our predictive models, enabling more accurate demand sensing and automated replenishment triggers. The system can even predict potential quality issues by monitoring storage conditions, preventing inventory losses before they occur.

How to measure predictive supply chain performance for shawls?

Implementing predictive systems without proper performance measurement leads to uncertainty about ROI and missed optimization opportunities. Traditional supply chain metrics often fail to capture the full value of predictive capabilities.

Measuring predictive supply chain performance for shawls requires tracking forecast accuracy, inventory turnover, service levels, and cost metrics specifically tailored to assess predictive system effectiveness. These measurements provide insights for continuous improvement and justify ongoing investment in predictive technologies.

What are key forecast accuracy metrics for shawl collections?

Forecast accuracy measurement focuses on tracking prediction performance across different shawl categories, time horizons, and geographic regions. We monitor Mean Absolute Percentage Error (MAPE) for seasonal shawl demand predictions, Bias for systematic over or under-forecasting, and Forecast Value Added (FVA) to quantify improvement over simpler forecasting methods. By analyzing accuracy at SKU-level for items like pashmina shawls versus category-level for casual wraps, we identify where predictive models deliver most value and where they need refinement. This detailed measurement approach typically improves overall forecast accuracy by 25-40% compared to traditional methods.

How to calculate ROI of predictive systems for shawl businesses?

Predictive system ROI calculation considers both tangible and intangible benefits specific to shawl operations. We quantify reduced inventory carrying costs from better demand matching, decreased markdowns from improved seasonal planning, and increased sales from better in-stock positions. For a typical shawl collection, the ROI analysis includes measuring reduction in safety stock requirements, decrease in expedited shipping costs, and improvement in customer satisfaction scores. Most businesses achieve full ROI within 12-18 months through a combination of increased revenue, reduced costs, and improved operational efficiency across their shawl product lines.

Conclusion

Implementing predictive supply chain management for shawls transforms how you plan, produce, and distribute your collections. By leveraging advanced data analytics, optimizing inventory across seasonal patterns, building robust technology infrastructure, and continuously measuring performance, you can achieve significant improvements in profitability, customer satisfaction, and operational efficiency.

If you're ready to implement predictive supply chain solutions for your shawl business, we invite you to contact our Business Director, Elaine. She can discuss how our manufacturing expertise and supply chain capabilities can support your specific needs. Reach her at: elaine@fumaoclothing.com.