The fusion of fashion and technology in smart textile accessories—think heated scarves, UV-sensing hats, biometric-monitoring headbands, or LED-integrated bags—represents one of the most exciting and challenging frontiers in manufacturing. For entrepreneurs and brands, finding the right partner to bring these innovative concepts to life is a critical and complex task. Unlike traditional accessory manufacturing, this requires a unique hybrid of soft goods expertise, electronics engineering, software development, and regulatory compliance knowledge. So, how do you navigate this specialized landscape to find a manufacturer capable of turning your smart accessory vision into a reliable, market-ready product?

As the owner of AceAccessory, while our core expertise is in traditional fashion accessories, we have cultivated a network of specialized partners and invested in R&D to meet the growing demand for integrated tech. The journey to find the right smart textile manufacturer is less about searching a broad B2B directory and more about identifying a collaborative partner with a proven interdisciplinary skill set. Success hinges on a methodical approach that evaluates technical capability, supply chain maturity, and project management rigor specific to this niche.

This guide will provide a structured roadmap for finding and vetting a manufacturer for smart textile accessories. We'll cover how to define your technical requirements, where to search for specialized suppliers, the critical factors for evaluation beyond basic manufacturing, and how to manage the prototyping and production process to de-risk your project. By the end, you'll have a clear action plan to identify a partner who can bridge the gap between circuit boards and couture.

How to Precisely Define Your Technical and Compliance Requirements?

Before you contact a single manufacturer, you must have absolute clarity on what you are building. Ambiguity is the enemy of innovation, especially when it involves multiple engineering disciplines. A precise product definition acts as your blueprint and filters for suitable partners. This goes far beyond a mood board; it requires a Technical Specifications Document (Tech Spec) that details both the textile and electronic components.

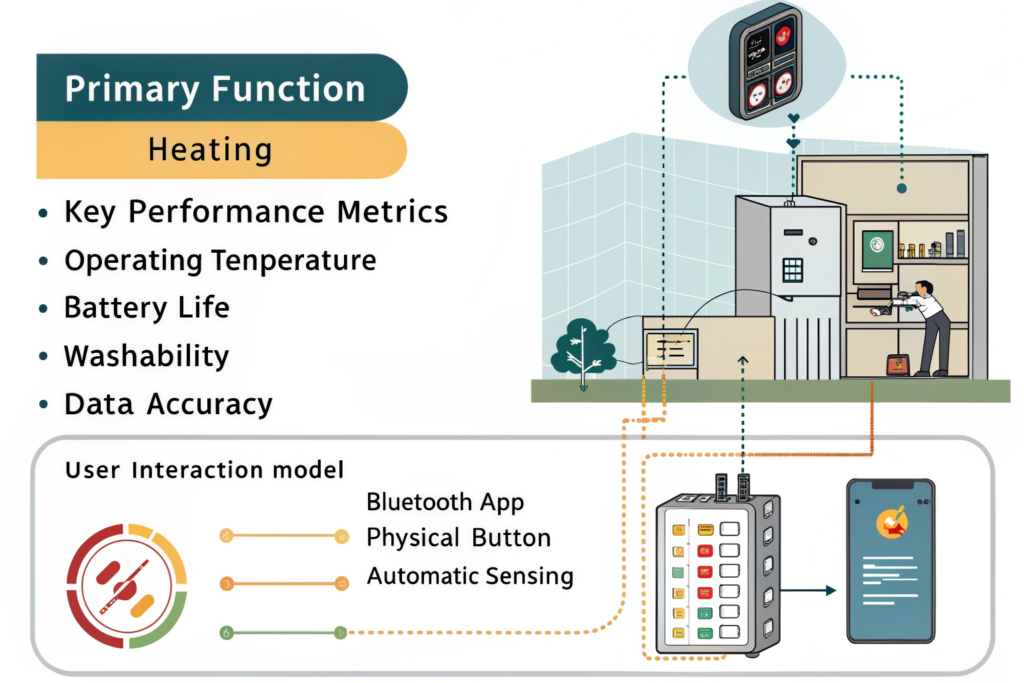

Start by answering fundamental questions: What is the primary function? (Heating, lighting, sensing, data collection). What are the key performance metrics? (Operating temperature, battery life, washability, data accuracy). What is the user interaction model? (Bluetooth app, physical button, automatic sensing). This clarity allows potential manufacturers to assess feasibility, identify challenges, and provide realistic timelines and cost estimates from the outset. For example, specifying that your heated glove must maintain 40°C for 4 hours on a single charge and survive 20 wash cycles sets clear engineering goals.

What should be included in a smart accessory Tech Spec?

Your document should cover these core areas:

- Textile & Industrial Design: Materials (e.g., moisture-wicking polyester, merino wool blend), construction details, dimensions, colorways, and intended fit.

- Electronics & Firmware: Detailed list of components (flexible PCB, LiPo battery, temperature sensor, Bluetooth Low Energy (BLE) module), schematic diagrams, power requirements, and firmware feature set.

- Software & Connectivity: App functionality requirements, data protocols, cloud integration needs (if any), and user interface design.

- Performance & Compliance: Target battery life, charging time, water resistance level (IP rating), washability standards, and relevant safety certifications (e.g., FCC, CE, RoHS for electronics).

- User Experience: How the user charges the device, pairs it, and interacts with it daily.

This document demonstrates your seriousness and enables manufacturers to conduct a meaningful initial assessment.

Why is regulatory compliance a primary early concern?

Smart accessories are often considered consumer electronic devices. This brings them under the scope of various international regulations covering electromagnetic emissions, battery safety, and material restrictions. Understanding the target market's compliance landscape (e.g., FCC for USA, CE for Europe) is crucial. A qualified manufacturer will have experience navigating these certifications and should be able to outline the testing process (often with third-party labs) and associated costs and timelines. Failure to plan for compliance can lead to blocked shipments, legal issues, and product recalls.

Where to Search for Specialized Smart Textile Manufacturers?

This is not the domain of general apparel factories. Your search must be targeted towards ecosystems where electronics manufacturing and textile innovation converge. Casting too wide a net with generic terms will yield irrelevant results and waste time.

Focus your search on the following channels:

- Tech & Wearable-Focused Trade Shows: Events like CES (Consumer Electronics Show), Wearable Technology Show, or Techtextil are prime venues. Here, you meet manufacturers who are marketing their smart textile capabilities directly.

- Specialized B2B Platforms and Directories: Use platforms like Global Sources or HKTDC with advanced filters for "wearable technology," "smart textiles," or "electronic accessories." LinkedIn can be powerful for finding and connecting with company engineers or project managers in this field.

- University and Research Institute Spin-offs: Many cutting-edge smart textile technologies originate in academic labs (e.g., MIT, Fraunhofer Institute). These often spin off into commercial entities or partner with manufacturers.

- Partnership Ecosystems: Consider a "split" partnership—a traditional accessory factory (like Shanghai Fumao) that manages the textile construction and partners with a specialized electronics assembly house. We often act as the system integrator and project manager for such collaborations, handling the seamless marriage of the two components.

How to vet a manufacturer's true interdisciplinary capability?

A website claiming "smart textile" capability is not enough. You must dig deeper:

- Request Case Studies: Ask for specific examples of past smart textile projects they have brought to mass production. What was the product? What were the technical challenges and solutions?

- Ask for Team Structure: Do they have in-house electrical engineers, firmware developers, and textile engineers who collaborate? Or do they outsource key functions?

- Inquire About Supply Chain: Where do they source key components like flexible batteries, conductive yarns, or waterproof connectors? A mature supply chain is critical for quality and scalability.

- Visit or Virtual Audit: If possible, visit the facility. A virtual tour can also reveal if they have dedicated SMT (Surface-Mount Technology) lines for small electronics, textile testing labs, and ESD (Electrostatic Discharge) protected areas for electronics assembly.

What Are the Critical Evaluation Factors Beyond Basic Manufacturing?

For smart accessories, standard factory audits for social compliance and stitching quality are necessary but insufficient. You must evaluate their technical development process, quality assurance for electronics, and post-production support.

The development cycle for a smart product is iterative and involves constant problem-solving. You need a partner with a structured Stage-Gate Process that moves from concept validation to functional prototypes (Proof-of-Concept), to engineering prototypes (looks-like, works-like), to pre-production and finally mass production. At each gate, there should be clear deliverables and testing criteria.

How is quality assurance different for smart textiles?

Quality control must be multi-layered:

- Component-Level Testing: Incoming inspection of electronic components and specialized fabrics.

- In-Process Testing: Checking solder joints on flexible PCBs, testing circuit functionality before encapsulation in textile.

- Assembly Integration Testing: Ensuring the electronic module integrates correctly with the textile component (e.g., no pinching wires, seals are waterproof).

- Final Product Testing: 100% testing of key functions (power-on, connectivity, sensor calibration) and statistical sampling for durability (bend testing, wash testing).

- Firmware/Software QA: Dedicated testing for the app and firmware to ensure a bug-free user experience.

Ask potential manufacturers to detail their QC protocols specifically for electronics-in-textiles. Do they have automated test jigs? What is their Mean Time Between Failures (MTBF) analysis?

What about firmware updates, repairs, and lifecycle management?

Smart products are "alive" with software. Your manufacturer should have a plan for:

- Firmware Update Distribution: How will end-users receive critical updates? (OTA - Over-The-Air updates via an app are standard).

- Repair and Return Logistics: What is the policy for defective units? Can they be repaired, or are they replaced? Is the product designed for disassembly?

- End-of-Life Support: How long will they support the product with software updates and spare parts?

A manufacturer that thinks about the entire product lifecycle is a true long-term partner.

How to Manage the Prototyping and Production Process?

The path from idea to mass production is paved with prototypes. Each stage serves a distinct purpose and de-risks the project. Expect to pay significant upfront costs for prototyping, as it involves custom tooling, small-batch PCB fabrication, and extensive engineering time.

A typical prototyping journey includes:

- Proof-of-Concept (POC): A rough, non-aesthetic prototype that validates the core technology works (e.g., the heating element heats, the sensor reads data).

- Engineering Prototype (Alpha): Integrates electronics into a more refined textile form. Used for functional testing, battery life optimization, and firmware debugging.

- Design Validation Prototype (Beta): Looks and works like the final product. Used for user testing, compliance pre-tests, and final design tweaks.

- Pre-Production Run (Pilot): A small batch (50-200 units) made on the actual production line with mass-production components and processes. This is the final check for manufacturing quality and consistency before the full order.

Why is the DFM (Design for Manufacturing) review crucial?

A DFM Review is where the manufacturer's engineers analyze your design for producibility, cost, and reliability. They will suggest changes to simplify assembly, improve durability, and reduce cost. For example, they might recommend a different method of encapsulating the electronics or a more readily available battery cell. Being open to this collaborative engineering phase is essential for a successful and scalable product.

How to plan for scalable production and inventory?

Discuss Minimum Order Quantities (MOQs) early. For smart accessories, MOQs are often driven by electronic components (custom PCB orders) and can be higher than for plain textiles. Plan a phased production strategy: a smaller initial run to test market response, followed by larger reorders. Ensure your manufacturer has a clear plan for sourcing long-lead-time electronic components to avoid production delays. Their role extends beyond making the product to managing a high-tech bill of materials (BOM).

Conclusion

Finding a manufacturer for smart textile accessories is a specialized quest that demands a partner with hybrid DNA—one that embodies the precision of an electronics engineer and the artistry of a textile master. Success requires moving beyond traditional sourcing playbooks to a process centered on technical vetting, interdisciplinary collaboration, and rigorous lifecycle planning.

The key is to start with crystal-clear technical specifications, target your search in tech-textile ecosystems, and evaluate partners on their integrated development and quality systems. Embrace the iterative, prototype-driven journey, and choose a manufacturer who acts as a true co-developer invested in your product's success from the first line of code to the final customer update.

If you are developing a smart textile accessory and seek a manufacturing partner with the technical network, project management rigor, and quality focus to bring it to life, we are positioned to facilitate that partnership. At Shanghai Fumao, we connect innovative brands with our vetted ecosystem of electronics specialists and manage the integrated development process. To discuss your smart accessory project, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build the intelligent future of fashion, together.